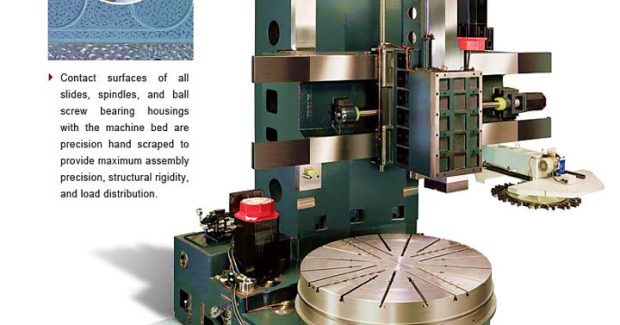

Vertical Turning Centers for Large, Heavy Parts

GV-1200M and GV-1600M vertical turning centers from Yama Seiki use highly rigid construction to easily overcome horizontal turning centers’ problems when machining large diameter, heavy weighted and non-symmetrical work pieces.

Posted: September 21, 2014

Packed with industry leading technology and top quality components, GOODWAY GV-1 series vertical turning centers from Yama Seiki USA, Inc. (Chino, CA) combine incredible power, strong constructions, and heavy duty cutting capabilities to bring you The Ultimate Machining Power.

These maximum performance machines will easily accomplish the demanding turning applications of today and tomorrow. GV-1 Series includes two different models with live turret, GV-1200M and GV-1600M. With GV-1200M and GV-1600M’s maximum turning diameter up to 1,350 mm and 1,800 mm, maximum weight load up to 5,000 kg and 8,000 kg accordingly, and available live tooling spindle and CF-axis capabilities, turning, milling, contour milling and drilling applications may be completed in one single machine.

The GV-1 series is built to endure years and years of rigorous high production turning; the heavily ribbed, thermally balance, high-rigidity bed and column are of Meehanite casting. It is capable of withstanding much greater stress without deforming, and it provides maximum vibration dampening, which result in a machine that will outlast and outperform the competition.

http://youtu.be/DnM1FudRnUI

A demonstration of the GV-1600 VTL.

By using Finite Element Methods (FEM), optimal reinforce ribbings are directly cast into the bed and column structure. Mechanical rigidity has been increased by more than 30 percent when compared to conventional designs. The GV-1 series is capable of performing super heavy-duty turning and maintain long-term super high-precision accuracy.

More rigidity also means extended tool life. The contact surfaces of all slides, spindles, and ball screw bearing housings with the machine bed are precision hand scraped to provide maximum assembly precision, structural rigidity, and load distribution.

Crossrail is mounted with 4 sets of up/down-positioning mechanism providing strong locking-positioning at each point which strengthens the overall rigidity of the crossrail and tooling spindle, thus assuring high accuracy for these series. The extremely rigid crossrail is designed with box-shaped structure to prevent thermal displacement and assure machine stability during turning operations.

W-axis travel is up to 800 mm for better machining flexibility. Pretension on all ground ball screws with extra wide ground box ways provide high rigidity for heavy-duty cutting. Crossrail can be moved up and down as desired to meet your requirements while the column is adopted with the high-low box way design to firmly support the crossrail to minimize structural distortion.

Instead of using partial belts, the GV-1200M and 1600M series uses all gears to connect the spindle motor and work table. With the standard high-speed ratio, high-torque 2-speed gear box mated with a 40/6,000i series spindle motor provides more output for heavy duty cutting. The optional CF-axis and disk brake system available on the GV-1 series provide the most rigid and powerful type of C-axis on the market today.

It adopted with worm gear drive system for high accuracy transmission and easy backlash adjustment. The indexing accuracy is up to 0.001 deg. Working with the live tooling turret, the CF-axis and disk brake system enables the machine to perform multiple tasks, such as drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations.

The GV-1 series uses overall highly rigid vertical turning center construction which can easily overcome horizontal turning centers’ problems when machining large diameter, heavy weighted and non-symmetrical work pieces.

YAMA SEIKI, 5788 Schaefer Avenue, Chino, CA 91710, 909-628-5568, 909-993-5378, [email protected], www.yamaseiki.com.