IMTS 2014: Gear Generation

Take a closer look at gear cutting, forming and finishing, as well as broaching, shaping and slotting machines for traditional auto, construction, mining and ship-building applications, plus the emerging alternative energy and wind power sectors. You’ll find advancements in abrasive machining to improve dressable tooling applications and increased multi-functional, automated solutions to minimize workpiece movements to improve overall production time.

Posted: August 5, 2014

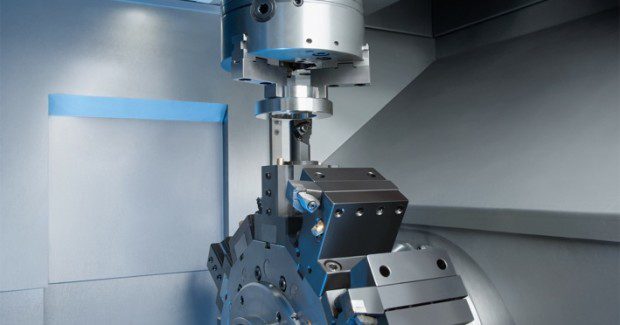

AUTOMATED SINGLE TABLE GEAR GRINDING SYSTEMS

In Booth N-6930, with a one-table design and a new-design grinding head, the new LGG 180 and LGG 280 machines from Liebherr Gear Technology, Inc. (Saline, MI) greatly reduce grinding times for twist-free profile and generating grinding.

The machines are designed to deliver consistent high large-scale production quality in automotive applications, including conical gearing. According to a Liebherr spokesman, “With this series of space-saving machines, vehicle manufacturers can develop a complete production line, in which all gearing components for a passenger vehicle transmission can be ground: planetary and sun gears, bore-type gears, as well as drive and pinion shafts with lengths up to 500 mm.

The new grinding head allows for rotation speeds up to 10,000 rpm and has spindle power of 35 kW. With this performance data, the head enables high cutting speeds and high feed rates. The new grinding machine can exploit the considerable potential of the innovative 3M abrasiveCubitron II. Changing the grinding arbor with HSK-C 100 tool holder is a fast and simple process. Also available is a second grinding head for featuring a small worm diameter for collision-critical parts.

The machine will enable undulations to be applied specifically to gear wheel flanks for noise optimization purposes for the first time. The ability to produce sub-µ range waviness cost-effectively gives designers a whole new range of optimization options. The touch screen user interface on the machine control permits easier, intuitive programming and machine operation and incorporates an integrated webcam. The control also can incorporate substantial additional documentation, such as fixture layouts and tool mounting instructions.

The LGG machines are easily coupled with Liebherr automation solutions to create a fully automated production line for the highest quality gears in the least possible cycle times. For example, at the show the company willdemonstrate a smart part handling solution that can remove randomly placed items from a container and place them accurately in a machine or production line, utilizing 3D image recognition system software, a robot, and a sophisticated handling strategy.

This intelligent removal of items, such as the automated picking of unsorted components, is referred to as random bin-picking. Specially developed grippers with additional axes enable collision-free access and the removal of items from the container, and subsequently allows for precise positioning of the item into a fixture or pallet.

The advantages of this scalable automation process include increased productivity, improved machine utilization rates, reduction of the need for additional machines to achieve desired plant production volumes, and more consistent production quality. Liebherr has created complete systems for, among other sectors, for the automotive industry. This includes the efficient channeling of non-rotationally symmetrical components which arrive randomly inside a bin and can be placed into production lines and hardening ovens. The beginning of a production line is the key point where picking from the bin is necessary.

An important breakthrough occurred with the object recognition system. The 3D laser scanner precisely recognizes the components for picking. Outside light of any type in the production building has zero effect on the ability to pick a part. It will even recognize black, brown and rusty parts. The accompanying software segments identify and select information about items and constraints in the bin provided. www.liebherr-us.com

MODULAR MANUFACTURING SYSTEMS

In Booth N-6846, EMAG LLC (Farmington Hills, MI) will feature Manufacturing Systems for Precision Metal Components with multiple machines from its new modular standard VL and VT product families on display. These Modular Standard Machines offer a systematic approach that is advantageous to establishing a highly efficient manufacturing process, with different operations offered on the same platform, allowing for easy interlinking and eliminating any great capital investment for automation.

The smallest lathe of the VL product family, the VL 2, machines workpieces with a maximum diameter of 4 in and a length up to 6 in. Increasing in size, the VL 4, VL 6 and VL 8 offer a number of different turning and milling operations within the framework of a single closed-loop production process. Specially designed for the handling of large components, the largest vertical turning machine of the series, the VL 8, ideal for commercial vehicle production, handles workpieces up to 16 in diameter and 12 in length.

An overview and demonstration of the VL 2 vertical turning machine.

Built within the same modular concept is the VT-Series for machining large quantities of shaft components. With four axes, a self-loading turret and integrated automation, the VT 2-4 machines shafts with a max diameter of 2.5 in and 16 in length. Spindle speeds of up to 6,000 rpm achieve extremely short cycle times as the shaft is clamped vertically between workspindle and tailstock and machined from two sides. The vertical alignment of the workpiece ensures process integrity, where the unhindered chip flow prevents the build-up of chip nests in the machining area.

All machines of the VL and VT product families offer the same advantages for every size workpiece:

- A pick-up spindle/turret loads the machine itself, picking up the raw parts from the integrated conveyor and returning the finish machined component.

- A 12-station tool turret known for very short indexing times. For drilling and milling operations, it can also be equipped with driven tools in all 12 stations.

- Service units that are quickly and freely accessible, making for short set-up and change-over times.

- A machine base made of MINERALIT® polymer concrete to ensure stability through outstanding damping qualities, resulting in exceptional surface finishes.

- Optional Y-axis.

Integrating the technologies of the EMAG Group into these new modular standards, the VLC 200 H will make its North American debut at the show. The VLC 200 H hobbing machine integrates EMAG-KOEPFER technology into the EMAG vertical platform, including the pick-up design, where the main spindle removes the raw part from the conveyor belt, transfers it to the tailstock flange and removes it from the machining area after the completion of the hobbing cycle.

EMAG will also present its entire portfolio of production technologies, from turning, hobbing and grinding to those that complement traditional metalworking processes, such as its production Laser Welding, Heat Shrink Technology and Electro-Chemical Machining (ECM) capabilities. ECM processes offer non-contact machining with no heat affected zone or mechanical stress to components with no tool wear. An ECM machined blisk will also be on display. EMAG invites manufacturers to visit and meet with technology experts to discuss production solutions for the automotive and commercial vehicle, aerospace and oilfield industries. www.emag.com