IMTS 2014: Controls & CAD/CAM

Here is the world of custom automation and the latest software that is needed to extract the maximum efficiency from your machine tool and optimize your plant operations with cost efficiency.

Posted: August 4, 2014

CNC TECHNOLOGY PUSHES THE ENVELOPE

From the job shop to the retrofit operation, moldmakers to mass production departments at the world’s leading auto, aero and medical manufacturers, Siemens Industry, Inc. (Elk Grove Village, IL) continues to push the envelope on CNC technology in Booth E-5010.

http://youtu.be/Rrq19uoQrpM

Ann overview of the Intelligent solutions for machine tools by Siemens.

With the introduction of the 808 at IMTS in 2012, we took a bold step into the job shop world, as this basic CNC brings the power, flexibility and reliable performance of Siemens technology to the job shop. Already accepted as an OEM component by numerous mill and lathe builders, the 808 provides job shops the unique opportunity to apply advanced and unmatched CNC power to their existing machines, breathing “new life into old iron,” as the saying goes. Simply put, nobody matches the muscle of Siemens. Come to and see the difference. Productivity in Motion! www.siemenscnc.com

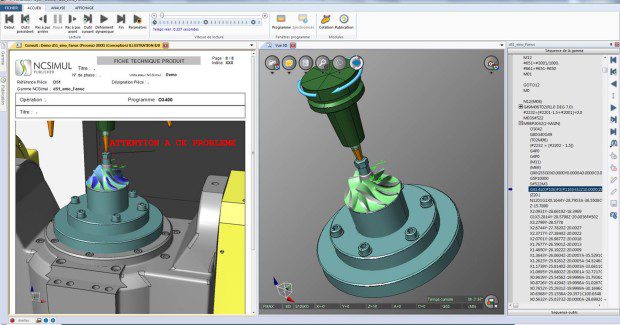

MOBILE AND SYNCHRONIZED NC SIMULATION SOLUTION – FIRST TIME IN U.S.

In Booth E-3267, SPRING Technologies Inc. (Cambridge, MA), the developer of software solutions that enable manufacturers to optimize their CNC machines will highlight the latest features, benefits, and applications of company’s flagship simulation software, NCSIMUL Machine and NCSIMUL Player 9.2. Specifically, with the growing adoption of remote and mobile software accessibility, SPRING will demonstrate its recently introduced mobile system called WYSIWYC® (What You See Is What You Cut).

“What WYSIWYC means to manufacturers is that we at SPRING Technologies are changing the way operators interact with CNC machines and rethinking the way procedures are accomplished on the shop floor,” explains Philippe Solignac, the corporate marketing director for SPRING Technologies. “We’re offering a unique user experience, which is very attractive to Generations Y and Z, with true shop floor-dedicated mobility with the ultra-rugged Toughpad tablet PC. It’s fun, it uses touch technology, and everything is digitized, including worksheets. It’s also a very effective methodology for conducting training modules without an additional large investment.”

According to Solignac, customers are achieving at least 25 percent higher productivity using the combined three technologies comprising WYSIWYC. He credits that because so much information about the program and process is immediately available, there are fewer errors, better decision making, smoother changeover between shifts, and easier multi-machine supervision. Also on display at the show:

Software: NCSIMUL Machine and NCSIMUL 9.2 Player – requires Windows 7 or 8

- Realistic preview of the process and real time 3D simulation of machines and machining showing what is really cut and operations currently in progress.

- Can extend to DNC machine status monitoring, ERP, MRP

- 100 percent Touch – smartphone type with NCSIMUL HUB apps / Multi-machine selection

- Instruction / Worksheets – NCdoc module

Hardware: CNC Control, such as Fanuc, and Panasonic Toughpad Tablet PC IP65 standard, 10 in format for readability, Intel Core 15 for 3D computing power.

A demonstration and overview of the power of CNC simulation with NCSIMUL Machine.

SPRING Technologies enables the optimal use of CNC machine tools, maximizing their productivity. Its “smart” solutions are integrated, intelligent, instrumented, and based on its “NCEXPERIENCE” philosophy. The NCSIMUL SOLUTIONS portfolio integrates the complete machining process, in real time, including cutting and tool libraries, post-processing, NC simulation, technical content publishing and DNC Monitoring.

Based in France, Germany, PR China and the U.S., the company, established in 1983, collaborates with manufacturers in aerospace and defense, transportation, energy, industrial equipment and medical devices sectors worldwide. NCSIMUL, NCEXPERIENCE, Optitool and NCdoc are registered trademarks of SPRING Technologies. www.springplm.com

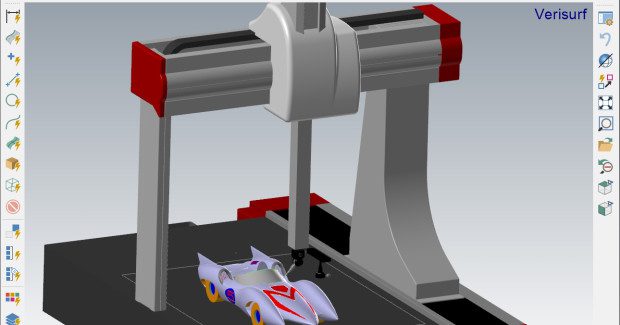

CMM AUTOMATION SOFTWARE MAKES PROGRAMMING FASTER, EASIER

In Booth E-3345, Verisurf Software, Inc. (Anaheim, CA) announces Verisurf AUTOMATE, a new CMM programming software that is revolutionary in its approach to inspection automation. It programs and operates CMMs faster, easier and at a lower cost with a 3D CAD measurement platform that automates all types and brands of coordinate measuring machines with an intuitive 3D experience, graphical object oriented programming and open standards that increase freedom of choice.

Verisurf AUTOMATE users are immediately productive with a rich 3D environment that includes an object oriented operations manager, CAD feature extraction, and solid model associativity. Ease of use and user productivity is enhanced with file recognition, logical right mouse click options, customizable user configurations and drag and drop operations reordering. Attention to the intuitive 3D experience helps users learn quicker, program their CMM faster and automate their CMM operation.

Verisurf AUTOMATE is a complete coordinate measurement CAD system, with 3D surface and solid modeling, traditional 2D drafting and 3D model associative GD&T that can accept any CAD model from your customers, including ACIS, AutoCAD, IGES, Inventor, KeyCreator, Mastercam, Parasolid, Rhino, Solid Edge, SolidWorks, SpaceClaim, STEP, STL, and VDA. Optional CAD formats include CATIA with FTA, Siemens NX, and Pro/E. AUTOMATE can even create CMM inspection plans to standard STL files to automate the inspection of 3D printed prototypes and additive manufactured parts.

CMM inspection plans created in AUTOMATE are compatible with all brands and models of Portable CMM Arms, Scanners, Laser Trackers, and Optical Trackers and programmable stationary CMM. In fact, the same measurement plan used to run a programmable CMM can be used with a portable arm. Whether the measurement job is on the shop floor or in the QA lab, this high level of interoperability empowers the technician to choose the ideal measurement device for the job.

Verisurf AUTOMATE complies to current and emerging non-proprietary, open standards, including DMIS and I++ DME Protocol for CMM communication supported by NIST, Renishaw and European automotive manufacturers Daimler, Audi, BMW, Opel, Volkswagen, Porsche, Volvo. Verisurf supports I++ DME to empower quality managers with inspection plan interoperability and freedom to inspect their parts with any brand or model of CMM and ultimately reduce recurring maintenance, training and support costs.

The software constantly maintains associativity between sequence tree objects and their corresponding 3D graphics display objects such as CAD model features, probe points, and probe paths. AUTOMATE extends Verisurf’s open 3D measurement platform strategy with inspection plans that can be executed on any supported stationary or portable CMM increasing flexibility, eliminating inspection bottlenecks and reducing training and support costs. Verisurf AUTOMATE is currently available to select customers and will be available to the general manufacturing community in August, prior to the show. www.verisurf.com