Turn Digital Tool Knowledge Into Machining Productivity

Take a look at how NOVO from Kennametal expands machine shop capabilities by efficiently turning digital tool knowledge into real-world productivity improvement.

Posted: July 29, 2014

Manufacturing is experiencing a global renaissance in developed and emerging economies around the world as major industries such as aerospace, automotive, energy and others consistently demand new and better products.

Manufacturing technology providers have responded with computer-driven machine tools, digital-based computer-aided design and manufacturing software (CAD/CAM), and significant advances in tooling. Yet behind this positive outlook lies a major barrier threatening this scenario: a significantly widening skills gap as older workers retire and new workers fail to engage in manufacturing careers.

“To effectively meet the skills gap for our customers, we need a better way to distribute our collected knowledge,” states Francois Gau, the vice president of strategic marketing and new business development at Kennametal Inc. (Latrobe, PA). “More than a catalog, NOVO brings users into a community — all of our ongoing expertise, delivered in a digital means of accessing process knowledge quickly. The result empowers users by providing the right solutions specifically tailored to their operations. It solves problems instead of managing data.”

Seamlessly interfacing with tool management, e-commerce, and other programs, NOVO powers shop systems that are hungry for accurate, timely tool knowledge. This is an advanced digital tool selector and process planner with real-world productivity results.

A webinar introducing NOVO and how it works in PC and tablet applications.

Since its groundbreaking launch in 2013, this digital tool and process planning application has continued growing by adding process capability constantly. Now, Version 1.3 is connecting via the cloud to tool management, e-commerce, and other shop systems, reducing data errors and making non-value-added data-transfer efforts things of the past

“Our vision from the beginning is to provide an open-source system that interacts seamlessly with shop systems needing to leverage cutting tool data and machining knowledge for productivity improvement,” says John Jacko, the vice president and chief marketing officer at Kennametal. “This is only the beginning of delivering the promise of the digital factory. Connecting to our ToolBOSSTM tool-management system via the cloud and streamlining input into our e-commerce system, that vision is quickly becoming reality.”

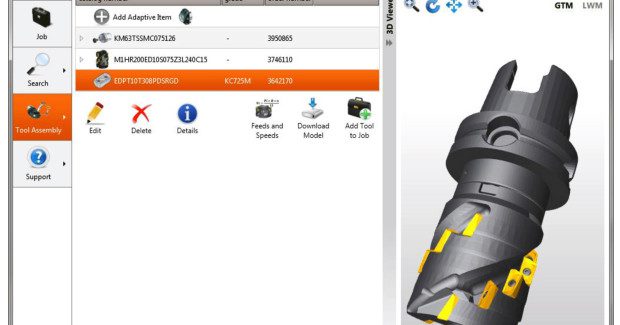

Customers expect continuous fast development of technology platforms to deliver more value. Since the original launch of the Tool Selector, Tool Configurator, Tool Advisor and Job functions, NOVO has added connectivity to E-commerce, easy ISO 13399 exports, and seamless integration to the ToolBOSS tool management system via the Machining Cloud.

Specifically, users can request a price quote from their local Kennametal distribution partners by transferring their shopping cart list to them via the “Request Quote” button. The distributor will receive a notification with complete detail of the items and requestor information to respond. A new pop-up also makes it easy to add spares and other individual items to existing shopping carts. Spare parts are clearly identified as “included” or “non-included” on bills of material.

ToolBOSS users on the cloud with the latest software version can now use the system to see if an item proposed for a process plan is already available in their ToolBOSS inventory, making both plans and budgets more efficient. Customer part numbers are automatically populated in Tool Advisor results and Tool Availability pop-ups via the ToolBOSS database.

“By adding ToolBOSS credentials to their user profile, customers easily check the inventory in their local ToolBOSS units with their developing process plans,” says Chris Merlin, the marketing manager for the Virtual Machining initiative at Kennametal. “They´re better able to visualize items already in their shop.”

NOVO can be used in a number of intuitive ways, from “I need to make a ½ in hole by 1½ in deep in ANSI 4140″ to “I need a ½ in by 5xD solid-carbide drill in grade KC7315.”

In the first case, the system helps users define machining features to drill a blind hole and then immediately reduces the product set to those that can do the job, taking into account the constraint requirements such as material, tolerance, and machining sequence for both single tools and multi-tools. The system then ranks the results — based on knowledge-based rules — to best meet the challenges of the application as defined by the customer´s operating environment and user preferences, providing far more useful process knowledge than any online catalog alone, all obtained in a fraction of the time.

In the second case, when a customer already has preferred tool and grade in mind, smart-attribute filters not only quickly select the products available to do the job but also gives the options on what cutting item and adaptive item fits and also works with the selected solution. These smart filters take the task of selecting all cutting tool components from hours to minutes, while users get the assurance that the list is both comprehensive and correct.

In both cases, the Tool Configurator then provides all CAD files and graphic support for all tool components and their assembly — a major time savings for customers.

“NOVO thinks like a process planner,” explains Thomas Long, the head of the newly formed Virtual Machining RDE department at Kennametal. “It works from the feature back to the tooling strategy. In addition, each order number is tied to application data gleaned from hundreds of subject matter experts and decades of our experience. Request a part number and you also get pictures, assemblies, spare parts lists, as well as inserts that fit. Not only does it accomplish in minutes what formerly took hours, it yields an optimized solution, backed by our expertise, every time”

Even further, the Job Functionality option is a cloud-based repository linked to a user by a unique ID where tool lists can be stored for future use, editing, copying, and sharing. These can be easily downloaded into standard report formats and include tooling commercial and dimensional data and weights, speeds and feeds, and photo or CAD model images.

Users can leverage NOVO via the tablet of their choice. “Mobility is no longer a luxury. With Android and Windows Tablet versions of the system now available, it brings an element of added mobility and access to your tool list no matter which device you log onto,” adds Merlin. “This also makes it easy for people working on the shop floor with tablets to collaborate with the process planners in other departments.

“Being “device agnostic,” NOVO avoids the “which app do I choose and use” or even the need to evaluate among multiple apps,” notes Merlin. “And once you log in, all your jobs data transfer is over, making organizations and teams much more powerful by extending process knowledge to those who need it.”

Celebrating more than 75 years as an industrial technology leader, Kennametal delivers productivity to customers seeking peak performance in demanding environments. The company provides innovative wear-resistant products, application engineering and services backed by advanced material science, serving customers in 60 countries across diverse sectors of aerospace, earthworks, energy, industrial production, transportation and infrastructure.

With approximately 14,000 employees and nearly $3 billion in sales, the company realizes half of its revenue from outside North America, and 40 percent globally from innovations introduced in the past five years.

Kennametal Inc., 1600 Technology Way, Latrobe, PA 15650, 724-539-5000, Fax: (724) 539-5022, www.kennametal.com.