Fast, Flexible Parts Transfer for High Speed Press Automation

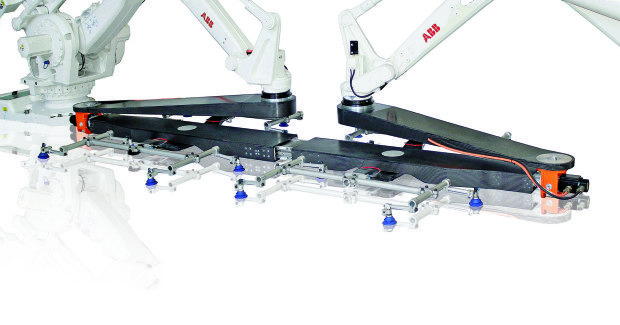

With a flexible robot-based solution, trouble-free change over and user-friendly programming interface, the Twin Robot Xbar from ABB Robotics is a cost efficient and reliable system for transferring big panels in tandem press lines.

Posted: July 2, 2014

ABB Robotics, Inc. (Auburn Hills, MI), which has been developing innovative robot-based press automation solutions for nearly two decades, has introduced the Twin Robot Xbar (TRX), a fast and flexible parts transfer system with an output rate of up to 16 parts per minute for big panels in tandem press lines. The TRX can be retrofitted to existing press lines, setting it apart from similar systems which require additional space between the upright and bolster.

“The TRX raises the bar in press automation, providing end-users increased speed and greater flexibility with the proven robotic technology that has served them well,” said Enrique Pano, the press automation manager of ABB Robotics, North America. “Customers benefit from improved performance with familiar technology. They maintain valuable consistency in terms of availability, spare parts, service, support and programming knowledge.”

Utilizing two robots optimally distributes the total power and load while minimizing the inertia in demanding press automation applications. With ABB’s MultiMove™ technology, a single robot cabinet controls all ten TRX axes, comprised of two four-axis robots plus two crossbar axes, simplifying programming without adding to the system footprint.

The system can accommodate a wide range of crossbar types and lengths to assure the right fit for different line configurations. Crossbar changes for new production have been fully automated on the press bolster or at the inter-press.

“Cost efficient and reliable, the TRX can tilt in three different axes and allows dynamic reconfiguration of part distance when moving double parts (side-shifting), eliminating the need for additional actuators,” adds Pano.

The TRX runs on StampWare, a proprietary software package from ABB designed to facilitate interaction between operator and press cell. Available on the robot FlexPendant for maximum sim¬plicity, flexibility and cost effectiveness, StampWare includes a graphical programming wiz-ard that helps operators easily program the robots with¬out having to master the programming language. It is currently running in more than 1,000 robots worldwide.

The ABB Group of companies, which operate in around 100 countries and employ about 145,000 people, are leaders in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact.

ABB Robotics is a leading supplier of industrial robots that also provides robot software, peripheral equipment, modular manufacturing cells and service for tasks such as welding, handling, assembly, painting and finishing, picking, packing, palletizing and machine tending.

Key markets include automotive, plastics, metal fabrication, foundry, electronics, machine tools, pharmaceutical and food and beverage industries. A strong solutions focus helps manufacturers improve productivity, product quality and worker safety. ABB has installed more than 200,000 robots worldwide.

ABB Robotics, Inc., 1250 Brown Road, Auburn Hills, MI 48326, 248-391-9000, [email protected], www.abb.com/us.