Advanced Safety Upgrade for Stainless Steel Rolling Mill

A new PLC and touchscreen operator panels create a networked control architecture of six safety zones, so that parts of a precision strip steel line can remain operational while an operator gains safe access to other zones under disabled power.

Posted: June 19, 2014

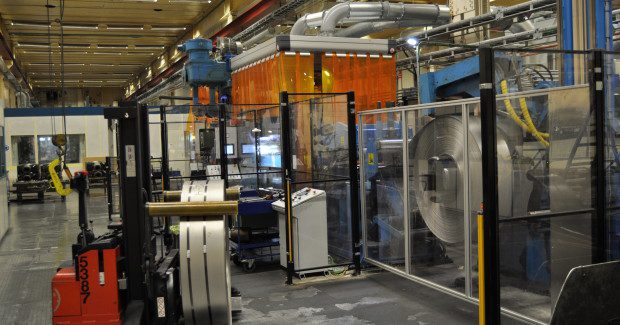

A new safety PLC from ABB Ltd. (Zurich, Switzerland) has provided the platform for Sandvik Materials Technology to add zoned safety guarding to a large cold rolling mill at its Sandviken plant in Sweden. The mill is a key part of the production line for precision strip steel at the plant.

The company’s cold rolling mill has been upgraded a number of times throughout its life – including recent changes that added servomotors, and new machine control, using ABB’s standard AC500 PLC and touchscreen operator interface panels.

The latest upgrade adds safety PLC modules from ABB’s AC500-S PLC to the machine control system to enhance the safety of the 20 m long mill with a networked architecture using the PROFIsafe protocol over PROFINET to provide independent control of six separate safety zones. The zoned arrangement means that parts of the machine can remain operational while an operator gains safe access to some other zone – where safety is assured by disabling power.

A basic course in how to commission the AC500 safety PLC onsite.

Some 50 safety PLC I/O channels are employed to link to gate switch and light curtain guarding, and emergency stop buttons. The I/O also monitors pressure switches to sense that hydraulic power is disabled so that maintenance can take place, and controls power supplies to the motor drives. Safe speed control is another aspect of the safety control provided by the new PLC – to ensure that hands or fingers cannot be trapped between the mill’s belt and rollers.

Sandvik chose ABB’s AC500-S safety PLC for this application because of good experience of the standard non-safety AC500 PLC architecture on both this machine and other machinery control projects. The AC500-S safety PLC also offered Sandvik the possibility of using floating point numbers, which simplified the safety programming required for this project for tasks such as calculating speed.

The fact that the standard version of the ABB PLC was already used on the mill measurably simplified the safety upgrade. This is because the safety PLC hardware shares the same look and feel as standard AC500 PLCs, allowing safety and non-safety functions to be mixed in the same system. This compatibility includes identical dimensions to CPU and I/O modules, and the same mounting and wiring scheme.

The new dual-processor safety CPU module and the safety I/O channels have been integrated alongside the machine’s existing AC500 PLC, which controls a total of six DC and AC drives and motors. The DC motors drive the main steel belt and rollers. The AC motors adjust roller position to achieve the desired pressure during strip steel processing. The standard PLC also links with four operator interface panels from ABB’s CP600 series.

Programming the safety solution was made simple by the fact that ABB’s integrated PLC development tool, Automation Builder, included support for safety PLC programming in its CODESYS-based integrated development environment – and support for the PLCopen Safety Library. ABB also provided its own safety code analyzer tool, SCA, which verifies the safety programming rules.

The familiarity of the programming environment and the sophistication of these tools helped Sandvik’s developers to quickly understand safety PLC programming concepts. This allowed them to develop the enhanced machine safety architecture in a very short time – meeting the company’s tight timescales set for this upgrade project – and quickly bring the enhanced mill into operation.

This project also took place before ABB had actually launched the AC500-S safety PLC. Prior to commercial release, the new PLC was extensively field tested in a large number of pilot applications. Sandvik was one of ABB’s pilot customers and developed this safety control system before the product and tools were launched, formally. This was made possible by good support from ABB’s product development team. Since this application, Sandvik has gone on to use the safety PLC on three other machine refurbishment projects.

“We were very pleased to find such an easy-to-apply solution for adding state-of-the-art protection, in the form of the ABB’s safety PLC – which integrated directly with the machine’s existing PLC,” says Torbjörn Pettersson, an engineering development specialist with Sandvik Materials Technology.

“The fact that ABB could supply the spectrum of machine control components required for this project, from the non-safety and safety variants of the PLC, to the operator panels, motor drives, contactors and safety hardware, both simplified and speeded this upgrade,” says Jonas Rehnberg of ABB Sweden. “The modularity of the new safety solution also means that it is now very easy to upgrade or modify safety functionality in the future, to enhance the safety of the mill even further, or to integrate additional aspects of the production process.”

The safety PLC – the AC500-S – is a recent addition to ABB’s well-known AC500 PLC range and features a dual processor architecture that complies with SIL3 (IEC 61508:2010 and IEC 62061)/PL e (ISO 13849-1) functional safety levels.

The integrated AC500-S safety PLC can run even if the non-safety PLC is stopped for maintenance. This means that personnel still easily can move within the machine during the maintenance phase, because the safety PLC will continue monitoring the state of the machine’s safety sensors and executing its safety function.

ABB Ltd., Affolternstrasse 44 CH-8050 Zurich, Switzerland, +41 (0)43 317 7111, Fax: +41 (0)43 317 4420, www.abb.com