Retooling at MAG Undergoes a Complete Overhaul

The German manufacturer can now retool Boehringer, Ex-Cell-O, Cross Hüller and Lamb machine tool and system overhauls and retrofits with state-of-the-art technology to meet the increased productivity requirements of customers.

Posted: June 24, 2014

"To make sure retooling projects do not produce any unexpected follow-up costs, we make sure that all the required information is included right from the start from all the segments concerned. Transparency and documentation always play an important role for us in the decision-making process and to ensure cost control."

"After a retrofit, retooling is absolutely essential because what is the point of an updated machine if it is going to be run with the same set of tools and use the same processes afterwards? - that would simply hinder the new productivity potential."

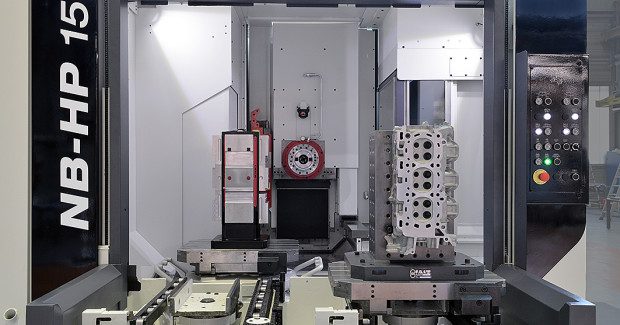

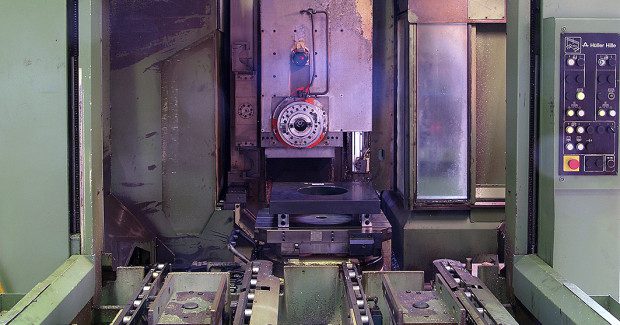

As a traditional service expert, tool manufacturer MAG IAS GmbH (Eislingen, Germany) is expanding its retooling activities. In connection with its machine tool and system retrofits, MAG is offering retooling mainly for its brands Boehringer, Ex-Cell-O, Cross Hüller and Lamb, but also for other brands.

This means that the machine tools are not only fitted with state-of-the-art technology afterwards but are also equipped to meet increased productivity requirements. From complete rebuilds to the machining of new components, subsequent retooling is part of the company’s core business.

Following a complete overhaul or rebuild, MAG retools the machine. This can take place either in MAG’s own plant in Göppingen or on site at the customer’s premises. The machine may then have more powerful drives and spindles and improved tool handling capabilities, it may be able to handle completely different feed rates and machining options: a machine that was previously only used for traditional machining methods may now be equipped for high-speed cutting.

The tools may have previously limited the number of workpieces and retooling opens up a whole host of new possibilities. The entire machining process is carefully scrutinized in the process, including NC programs, control, tool supply and travelling distances. The quality is just as good but the cycle time is reduced and productivity increases.

“After retrofits and rebuilds, we carry out retooling so that manufacturing plants can make the most of their refurbished machine,” says Jochen Wiedmann, the director of operations at MAG in Göppingen. “This makes new procedures and cutting patterns possible which can significantly raise machine efficiency and greatly increase the quantity produced. When we carry out a machine rebuild to process new components, it is fully retooled anyway.”

MAG is also able to carry out extensive work at the customer’s premises if the transport routes for the machine tools are too long and transport would be costly. The retrofit machines are also equipped with the most appropriate precision tools at the customer’s premises and commissioning of programmes and processes is carried out there too.

“To make sure retooling projects do not produce any unexpected follow-up costs, we make sure that all the required information is included right from the start from all the segments concerned,” says Axel Moch, the sales director of service at MAG in Göppingen. “Transparency and documentation always play an important role for us in the decision-making process and to ensure cost control.”

Due to MAG’s long-standing experience, especially in crankshaft machining on Boehringer machines, the company has become a competent partner in the automobile industry in particular. The machine builder supports companies from the planning and development stage through to implementation of an idea and on to pilot production. In this way, customers can use the latest technology right from the start with optimal system configuration.

For example, if a rotating function can also be integrated into a deep-hole boring machine, the customer can save himself a whole line. He would then only need one machine instead of two which not only considerably reduces purchase and maintenance costs but also means less space is required in the production halls. This has a particularly positive impact in industrial conurbations.