Parts, Cameras, Scan!

Unprecedented speed, accuracy and ease-of use, combined with the fastest paths ever from art to part, make it tough for progressive shops to ignore an investment in 3D scanning.

Posted: June 6, 2014

The new generation of 3D scanners is setting unprecedented standards in inspection and measurement that lift them to a category of their own with respect to speed, accuracy and ease-of use, and with ever faster paths from 3D scan data to CAD and machine tool or 3D printing/additive manufacturing workflows. This major leap in performance means shops are not only getting the ultimate, easy-to-use precision solution for 3D scanning, but also the ability to reduce their total cost of ownership for the system by getting up and running without the complexity of learning additional third party software. Let’s take a closer look at some of the capabilities these latest 3D scanning systems offer to your quality program.

AUTOMATED LASER SCANNING

Steinbichler Optotechnik GmbH (Neubeuern, Germany), a worldwide leading provider of optic measuring and sensor technology, has partnered with Metrologic Group S.A. (Inovallée, France) to mount their T-SCAN CS hand-guided laser scanner on the flexible Metrolog X4 i-Robot for automated measurements both on and off the production line. Metrolog X4 i-Robot measuring software operates with a multi-axle robot arm. The robot serves merely as the tool holder, with no requirements on specific precision, manufacturers or types.

Measurement precision is assured by means of a separate tracking camera that follows the T-SCAN CS, which is equipped with positioning LEDs. This system is ideal for inspection on production lines in the automotive, aeronautics and space industries and their suppliers, where Metrolog X4 i-Robot opens the door to adaptive measurements that make any robot programming as simple as a CMM.

http://youtu.be/Gd-FWblbs20

An overview and demonstration of the T-SCAN CS system from Steinbichler.

Steinbichler also offers their innovative combination T-SCAN LV / T-TRACK LV scanning and tracking system for large-volume measurement with consistently high precision. The tracking volume handles up to 35 m³ for the greatest possible freedom of movement and an efficient measuring process. Non-fatiguing work is assured through the compact dimensions of the T-SCAN LV scanner. The overall modular concept, with its controller box and the easy-to-connect central wiring, is ready to use in only a few minutes. Combining the T-SCAN LV hand-guided laser with the ergonomic T-POINT LV touch probe makes individual point measurements quick and uncomplicated and enables precise 3D data recording for nearly all applications – particularly the inspection of large objects.

An overview and demonstration of the T-SCAN LV / T-TRACK LV scanning and tracking system from Steinbichler.

With the ‘Dynamic Referencing’ function, the T-TRACK LV precisely measures moving objects or objects in an unstable environment. Connecting multiple T-TRACK LV trackers provides even greater freedom of movement for measuring large objects. This makes changing the position of a tracker superfluous and measuring speed is increased, even with complex shapes.

Another highlight from Steinbichler is the ‘Intelligent Light Control’ (ILC) used to detect highly reflective parts with their COMET 6 high-end sensor. Through the innovative and consistent advancement of strip light projection, ILC makes it possible to dispense with the common spraying of various measurement parts. Due to the automatic recognition of components, required parameters adjust automatically and elaborate correction and adaption of various factors, such as component length or illumination time, can be omitted. The result is increased measurement speed and simplified handling of the system.

ILC independently analyzes the recordings of the COMET 6 sensor. In areas where there is excessive exposure or radiation due to an excessive influence of light on the component, the amount of projection light is automatically reduced. With the digital projection unit, the COMET 6 sensor can project a multitude of gray values and thus project a special gray value for each area of the component.

Strip light sensors like the COMET 6 enable quick and highly precise measuring and scanning of a variety of parts. Particularly with highly reflective components, such as sheets, reflections and thus overexposure or underexposure of individual areas of components can occur, which can then result in a potentially diminished data quality. In ILC, a process with so-called adaptive projection, Steinbichler has developed a solution to this challenging problem for the first time.

Steinbichler also offers their latest 8 megapixel sensor COMET L3D 8M. The development of this device makes use of continuously improved one-camera technology. In comparison to competing systems on the market, the COMET L3D 8M offers detailed results in the premium segment and remains true to the COMET L3D series in terms of pricing, resulting in an unbeatable price-performance ratio.

http://youtu.be/nmTHnTObOoY

An overview and demonstration of the COMET L3D scanning system from Steinbichler.

The package, consisting of the COMET L3D 8M sensor and COMETplus software, offers all the necessary functions for easy and efficient work processes. COMETplus software and the integrated correction models enable the COMET L3D 8M to render impressive data quality and density. Single and multi-axis rotary tables are available as accessories that fully enable automated measurements in connection with the COMETplus software and, therefore, also a very comfortable entry-level solution in automated optical measurement technology. The COMET L3D 8M is particularly convincing with its high degree of detail, providing high resolution structures even for larger measurement fields.

Steinbichler Optotechnik GmbH, Georg-Wiesböck-Ring 12, 83115, Neubeuern, Germany, +49-8035-8704-769, Fax: +49-8035-1010, [email protected], www.steinbichler-cs.de.

TACTILE PIPE MEASURMENT

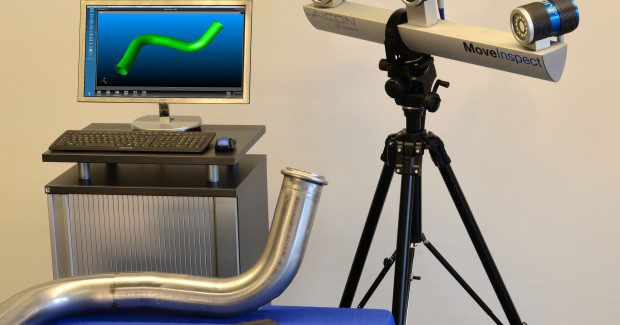

For all operators in the field of piping, AICON 3D Systems GmbH ((Braunschweig, Germany) offers an easy-going, convincing quality control: the new software platform BendingStudio, together with the optical 3D measuring system MoveInspect HR and the handheld MI.Probe – the ideal solution for tactile pipe measurement! BendingStudio connects all data and processes around the production of bended parts so that manufacturers can monitor, quantify, visualize and document all changes in various process steps. MoveInspect HR is easy to handle, portable, flexible and highly reliable and works with constant process reliability under difficult conditions on production floors with dirt, dust or vibrations.

An overview and demonstration of BendingStudio from AICON being used to measure large tubes.

Since the beginning of 2013, BendingStudio and MoveInspect HR has been successfully used at a customer’s site for daily technical inspection. Measuring tasks are the acquisition of data regarding the main dimensions of the tube, ovality of the curve, torsion angles as well as bending radius and bending angles. Besides tube measurement, other measuring tasks are also possible, such as measuring profiles and free-form bended tubes. It is extendable for further inspection tasks.