Coolants, Lubricants, Metalworking Fluids

Take a look at some of the coolant, lubricant, and metalworking fluid technology being used by shops to increase their metalworking productivity, keep their machine tools clean, and reduce their cost of operations.

Posted: June 7, 2014

Trends regarding the condition of the fluid can be analyzed over a long period of time to calculate consumption and top-up volumes. The app can be utilized as a troubleshooting guide source. And with consistent use of the app combined with a proactive maintenance approach, overall system performance can be optimized thereby helping customers improve productivity. What’s more, the app is easy to navigate and user-friendly. It remains advertisement-free so shops can enjoy uninterrupted usage. CoolanTool™ is available in English, Chinese and Russian.

“We are committed to providing solutions to a global customer base, so developing an app was a show of ingenuity,” states Jon Plawchan, the Quaker global product manager for metalworking. “By adding the CoolanTool™ mobile app to the marketplace, we’ve made it extremely easy for users to gather information and access troubleshooting tips.” For more information about this new app, visit quakerchem.com/haveyouseenourapp.

Quaker Chemical Corporation, One Quaker Park, 901 E. Hector Street, Conshohocken, PA 19428-2380, 610-832-4000, Fax: 610-832-8682, quakerchem.com.

FIRST SYNTHETIC LUBRICANT FOR AUTOMOTIVE ELECTRO GALVANIZED AND GALVANEALED METALS

IRMCO® Advanced Lubricant Technologies (Evanston, IL), a manufacturer of oil-free metal forming and tube bending lubricants, has formulated the first ever synthetic stamping lubricant for automotive electro galvanized and galvanealed metals. Traditional oil, pigmented and fatty-based products and the mess they create are no longer required to be used on Zinc coated sheet metal.

IRMCO® invented the first synthetic lubricant 32 years ago in 1982 and has continued to focus on and improve the non-oil lubricant category for the last 30+ years, specializing in only polymer synthetic, non-oil stamping and tube bending alternatives. This new line of 892 and 313 series lubricants have shown great results on automotive zinc coated sheet metals. No longer is staining or increased corrosion a result of non-conforming lubricants. Both IRMCO® product series remove these barriers and allow technologically advanced products to increase tool performance and many other production processes.

The company also provides LeanGreen® non-oil metal-forming fluids and gels as well as engineering services to help shops optimize in more than 80 manufacturing, assembly, and environmental areas. With operations in over 35 countries, IRMCO technology is used in manufacturing many critical components in automobiles, light and heavy trucks, exhaust systems, seating, class ‘A’ trim, aircraft, turf maintenance, recreational vehicles, motorcycles, appliances, pressure vessels, and other products.

IRMCO Advanced Lubricant Technologies, 2117 Greenleaf Street, Evanston, IL 60202, 847-864-0255, www.irmco.com.

TAPPING FLUID FOR DEMANDING TAP AND THREADING APPLICATIONS

TapRite™III Tapping Fluid, a high performance tapping fluid manufactured by JTM Products, Inc. (Solon, OH), features an advanced formulation for demanding tapping and threading applications in ferrous metals. It provides increased tap life and excellent lubricity in steel alloys and other severe uses as well as mild steels.

TapRite III is an ideal replacement for the popular Moly-DEE™ tapping fluid, which has been discontinued by its manufacturer. Free samples are available to qualified personnel. To get a sample, please call JTM for the distributor nearest you. TapRite III fluid is available in 16 oz bottles as well as 1 gal and 5 gal pails.

JTM Products has over 119 years of experience in manufacturing industrial lubricants, including KoolRite™ Long Life Coolants for metalworking.

JTM Products, Inc., 31025 Carter Street, Solon, OH 44139, 800-229-6744, Fax 440-287-3095, [email protected], www.jtmproductsinc.net.

PEDESTAL LUBRICANT SYSTEM FOR STAMPING OR DRAWING APPLICATIONS

Patented Spra-Rite lubrication systems from Industrial Innovations Inc. (Grandville, MI) precisely regulate the volume and placement of lubricant at specific areas of stamping or drawing tools, or the stock, at predetermined press stroke intervals. Use of these systems will improve production rates, reduce lubricant consumption for improved environmental conditions and, most importantly, save money.

A job shop testimonial of the Spra-Rite airless spray application from Industrial Innovations.

Spra-Rite system precision is enabled by independently-controlled, electrically- operated, efficient injector valves. These injector valves are micro-processor controlled, eliminating the need for any poppets, O-rings or check valves found in less effective application devices. Key to the system’s precision is the independent programming capability of each injector in terms of lubricant applied. There is ability to store and recall up to 200 spray pattern profiles with easy editing of existing programs as well as BCD-capability to communicate with most press controls. Additionally, press cycles can be skipped based upon pre-programmed stroke counts.

The pedestal systems come with a minimum Two-Injector Manifold to a maximum 48- Injector Manifold assembly with a choice of air-over-lubricant or air-driven-pump pressurization and delivery. Spra-Rite controls include a PLC and a data display with alpha-numeric programming of the valves, nozzle purge or test, and dual alarm outputs for management of the safety features. Spra-Rite’s design allows customers the ability to custom design a system to meet their specific process requirements.

Industrial Innovations is a leading manufacturer of industrial lubrication equipment for operation in the metalworking industries, including die casting, metalforming, machining and stamping. The company is known for its comprehensive approach to lubrication solution development, supported by the effective engineering principles, reliable components and quality construction of its equipment.

Industrial Innovations, Inc., 2936 Dormax Street SW, Grandville, MI 49418, 616-249-1525, Fax: 616-249-0983, [email protected], www.industrialinnovations.com.

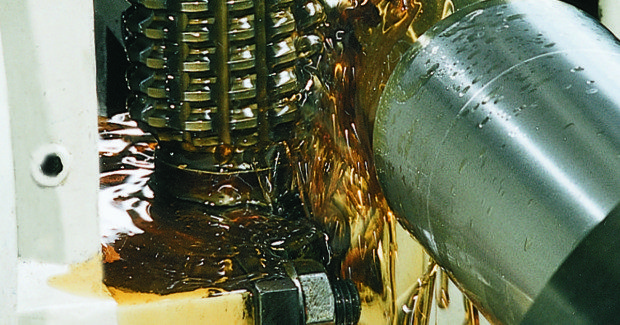

HIGH-PRESSURE COOLANT SYSTEMS EXTEND TOOL LIFE, IMPROVES FINISHES, CONTROLS CHIPS

HP Cool Tech, Inc. (Oxford, MA) manufactures Power Pump high pressure coolant systems for manufacturing processes. Systems include non-reservoir and reservoir pumps for CNC machine tools including Swiss screw machines, turning centers and milling machines. Integrating the HP Cool Tech’s compact Power Pump saves floor space and eases installation to a simple moveable unit with neat precise hose routing.

The Power Pump series are designed to allow the filter bag to be changed in five minutes or less. All the series systems alert the operator when the filter bag is approximately 75 percent full so the filter bag change can be scheduled at an opportune time.

Power Pump has an infinitely adjustable output by port with the HMI touch screen option. The HMI visually displays the Power Pump operating conditions at all times. All the coolant flow goes directly to the designated tool at the pressure selected and no flow is diverted across a relief valve, reducing the generation of heat in the coolant. Machining experts themselves developed and engineered Power Pump coolant solutions technology for optimal use in the manufacturing environment.

HP Cool Tech, Inc. was formally known as D.P. Tech, Inc., founded in 2004 and has grown into a full service High Pressure Coolant (HPC) systems manufacturer, located in the Oxford Industrial Park in Oxford. The company operates a 4,000 sq ft manufacturing facility specializing in high pressure coolant systems, replacement parts and related tool holders. HP Cool Tech’s products are sold and distributed throughout North America.

HP Cool Tech, Inc., 15 Industrial Park Road East, Oxford, MA 01540, 508-326-6922, Fax: 401-568-2428, [email protected], www.hpcooltech.com.