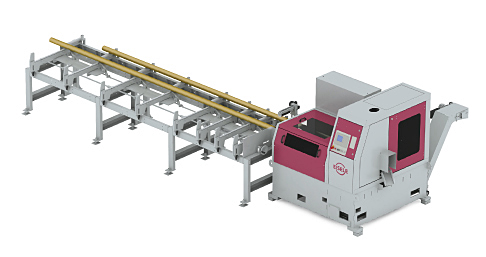

Carbide Circular Cold Saw with Fully Automated Inclined Magazine

For shops that need bulk cutting capabilities with minimal labor, the HCS-90E carbide circular cold saw from Behringer Saws meets high volume production demands with unattended operations.

Posted: June 28, 2014

Behringer Saws, Inc. (Morgantown, PA), a world-class provider of bandsawing machines, circular cold saws and structural fabricating equipment, has added an automated inclined magazine to its HCS-90E carbide circular cold saw. The newly packaged HCS-90E now meets high production demands while minimizing the need for operator attendance. “Behringer has designed the HCS-90E saw for customers that literally need bulk cutting output in the thousands of pieces per day range,” said Joe Suydam, a Behringer sales and marketing associate.

A fully automatic high-performance circular cold saw, the HCS-90E is designed for cutting ferrous material at 90 deg in maximum yield applications. High throughput performance is facilitated by the saw’s inclined magazine which holds up to 3500 lb of 12 in long material. An optional extension expands material capacity to 20 in long pieces and load capacity to 5250 lb.

Once loaded with bundles, the machine will run without interruption, cutting pre-programmed lengths, ejecting trim and remnants and channeling good cut pieces to a holding bin. This functionality is fully automatic without requiring operator standby. “Depending on raw bar lengths, the number of bars on the inclined magazine and the finished cut lengths,” said Suydam, “it’s entirely possible that an operator who loads a bundle of material at the beginning of a shift would not need to attend the machine for the remainder of that shift.”

The saw is equipped with a PLC-controller which permits programming the number of pieces to be cut, length, discharge handling and other parameters. Integrated sensor technology helps assure virtually non-stop throughput by detecting the leading and tail edge of the material being cut and automatically managing the feed rate. In this process, the back end of the material being cut travels past a light barrier in the machine. This signals the magazine to automatically load and stage the next bar onto a roller conveyor for entry into the saw. The machine will repeat this process until the supply of stock in the magazine has been exhausted.

The feed gripper unit is powered by a servo-driven ball screw spindle and encoder. This provides an infinitely variable feed or reverse feed rate of up to 39.3 in per second. Single stroke capacity is 0.314 in to 39.3 in and multiple stroke is up to 393.6 in (32.8 in). To assure optimum alignment of material entering the gripper clamping area, Behringer added a material shifting device to the gripper feed unit. This facilitates smooth handling of material to help prevent marking or scratching and is beneficial for high volume jobs.

The HCS-90E blade diameters measure from 9.8 in (250 mm) to 12.4 in (315 mm). The saw uses long lasting carbide-tipped disposable blades to provide fast, precision cutting of round stock up to 3.5 in (90 mm) diameter. A 10.7 hp frequency controlled saw motor enables blade speeds of 25 rpm to 215 rpm which facilitates cutting high-alloyed heat resistant steels and other ferrous materials. The entire sawing head is mounted on pre-tensioned linear ways angled at 25 deg and the worm gear driving the saw blade has been engineered for backlash-free motion. This enhances smooth cutting action and promotes long blade life.

Pressure-balanced, controlled blade movement helps maintain consistent production rates and improves cutting accuracy on both solid and tubular material. There is also an automatic material retract feature on the input side, and an automatic material release on the output side. This protects the carbide blade when the saw head returns to its “Home” position after completing a cut. Behringer’s robust machine design helps assure long blade life. Vibration absorbers mounted between the machine base and the sawing unit further enhance long blade life by eliminating vibrations which also enhances cut quality.

Behringer Saws provides a full range of sawing and turnkey pre- and post-cut material handling productivity-enhancing products by suppling world-class quality automatic bandsaws to corporations, service centers, job shops and manufacturers throughout the world. The company also offers the Behringer Eisele brand of manual, semi-automatic and automatic miter circular cold saws, high performance circular cold saws utilizing bi-metal or carbide saw blades and CNC miter circular sawing systems.

Also, the Vernet Behringer line of structural fabricating equipment includes high performance drilling, punching, shearing, notching and marking machines along with beam coping and drilling and sawing lines.

Behringer Saws, Inc., 721 Hemlock Road, Morgantown, PA 19543, 888-234-7464, www.behringersaws.com.