Weld Seam Monitor For Existing Seam Welders

The VeriWeld-SE™ Weld Seam Monitor from Taylor-Winfield records, analyzes and stores machine operating and weld schedule parameters using customer defined preset variables to validate weld quality.

Posted: May 20, 2014

The VeriWeld-SE™ Weld Seam Monitor from Taylor-Winfield Technologies, Inc. (Youngstown, OH) is designed in response to customer demands for continuous “real-time” feedback of machine performance and welder operation validation for new and existing coil joining welders.

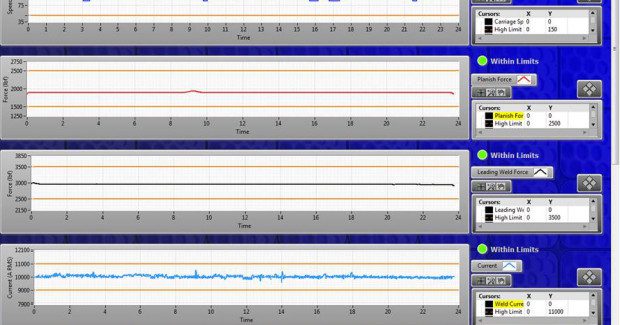

The goal of the VeriWeld-SE™ is to prevent costly weld breaks by identifying potential problems before the weld is released into the processing line. As a secondary benefit, the monitor also assists in identifying items on the machine, such as weld head bearing failure, secondary shunting, shear blade wear, and other preventative maintenance issues that should be addressed for optimal machine performance. Full integration is available for any existing manufacturer’s welders.

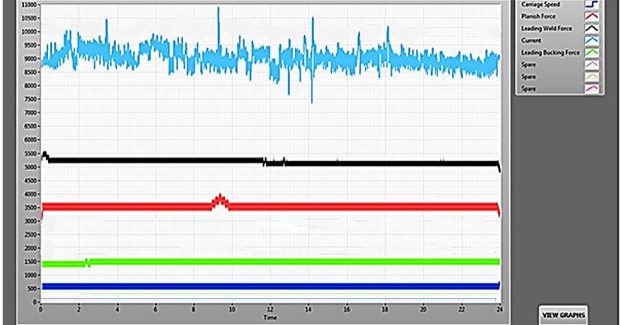

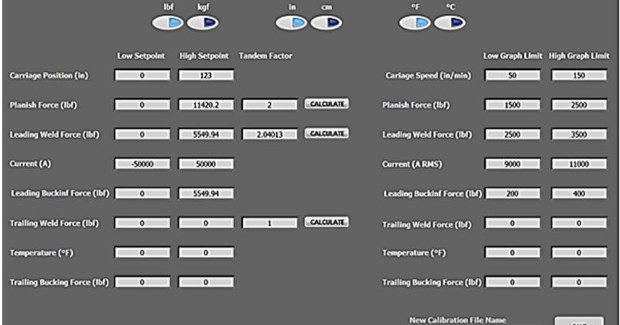

The VeriWeld-SE™ Weld Seam Monitor records, analyzes and stores machine operating and weld schedule parameters using customer defined preset variables to validate weld quality. The weld data is read at 2,000 samples per second and the results are archived within the system and transferable to MS Excel and “upper level” SPC and SQC systems. This technology was developed in the company’s Research & Development Laboratory in collaboration with several major steel producers.