Understanding the Basics of Flux-Cored Wires

As with any filler metal, welders must weigh out the advantages and disadvantages of gas-shielded and self-shielded FCAW wires to determine if these are the best choice for their specific application.

Posted: May 12, 2014

With all the filler metal options there are, it’s no surprise that there is often confusion about making the right choice for a given application. From stick electrodes to tubular wires, every type of filler metal offers unique welding characteristics, operator appeal and results. Flux-cored arc welding (FCAW) wires are no exception. And while these wires certainly aren’t new (they’ve been around since the 1950s), many questions seem to arise about the two varieties and their best uses. To help understand this type of tubular wire, consider some of the following basics.

FCAW WIRE TYPES

FCAW wires are available in two varieties: gas-shielded and self-shielded. Both types of wires have an outer sheath and contain a compound called flux. Flux includes a mixture of alloys and deoxidizers that help protect the weld from contaminants that could lead to defects such as cracking or porosity.

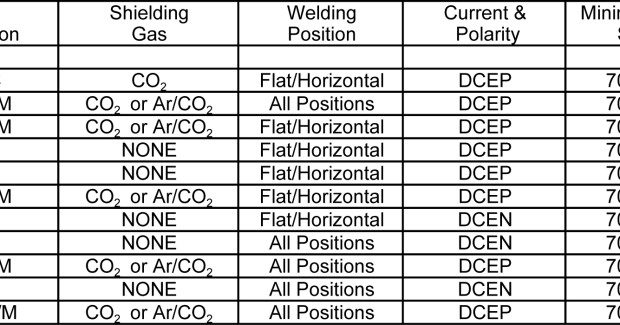

Gas-shielded FCAW wires, as their name implies, require an external shielding gas supply to protect the molten metal during the welding process. They use either CO2 or a mixture of Argon/CO2 as the shielding gas. CO2 provides good penetration, but may create more spatter and generate a less stable arc.

Conversely, a mixture of Argon/CO2 reduces spatter levels and provides good arc stability. Argon/CO2 shielding gas mixtures also reduce the fume generation rate of the wire. These mixtures, however, also lower the penetration capability of the electrode and therefore, are not always a suitable option.

An overview and demonstration of Hobart Element™ Low Manganese Flux-Cored Wires.

Because these FCAW wires rely on the shielding gas to protect the molten metal from the atmosphere, welding operators must remember to protect the arc from wind and drafts that could blow the shielding gas away from the molten weld puddle. Common applications for gas-shielded flux-cored wires include general fabrication, pressure vessels, petro-chemical piping and heavy equipment manufacturing.

Self-shielded FCAW wires do not require an external shielding gas; instead the flux within the wire generates the shielding to protect the weld pool. Self-shielded FCAW wires work well for outdoor welding applications such as structural steel, equipment repair and bridge construction because welding operators do not need to transport gas cylinders to use them. Also the shielding provided by the wire is less susceptible to the windy conditions often encountered in the field.

Both gas-shielded and self-shielded FCAW wires are available for joining a variety of base materials, including mild and low-alloy steel, and stainless steel. FCAW wires are also available for various build-up and hard surfacing applications, and for welding in the flat/horizontal position or in all positions.

WIRE DIAMETER AND CONTACT-TIP-TO-WORK DISTANCE (CTWD)

Filler metal manufacturers offer both gas-shielded and self-shielded FCAW wires in multiple industry standard diameters, generally ranging in diameter from .030 in to 1/8 in. Each wire classification or type, however, is typically available in a smaller range of diameters. As an example: all-position, gas-shielded FCAW wires are typical produced in diameters ranging from .035 in to 1/16 in diameters.

Recommended contact-tip-to-work distance for FCAW wires range from as low as 1/2 in to as much as 2-3/4 in. Wire manufacturer’s recommendations for CTWD depend on the wire classification or type and the wire diameter. It is important to always follow the recommendations for both types of wires.

POWER SOURCE CONSIDERATIONS

FCAW wires operate using straight polarity (DCEN or Direct Current Electrode Negative) or reverse polarity (DCEP or Direct Current Electrode Positive) according to the specific wire. Most can be used with either constant voltage (CV) or constant current (CC) systems, but there are self-shielded FCAW wires that are not recommended for CC systems, as well as codes that do not allow a CC system to be used for code work. Always check with the wire manufacturer and consult the welding code before attempting to use CC welding systems with these wires.

The composition of the specific wire also determines whether it can be used for single- or multiple-pass welding. It is best to consult with the filler metal manufacturer or distributor and read the packaging label and/or the wire’s specification sheet for exact operating parameters.

ADVANTAGES AND DISADVANTAGES

Both gas-shielded and self-shielded FCAW wires have advantages and disadvantages. Both types of wires can provide higher deposition rates than solid wire or stick electrodes and are relatively easy to use, making them a more productive filler metal choice for many applications. These wires also are capable of welding thick materials, while providing a good weld bead appearance, high-strength welds and strong impact values. They can also be alloyed to match different base materials and tend to be tolerant of contaminants such as dirt or mill scale, which can help welding operators reduce their pre-cleaning activities.

The biggest disadvantage of FCAW wires is that they produce slag, which welding operators must remove between passes or after the final weld placement by chipping or wire brushing. In some cases, these wires can also be more expensive per pound than other filler metals, particularly solid wires.

As with any filler metal, welding operators will need to weigh out the advantages and disadvantages of gas-shielded and self-shielded FCAW wires to determine if these are the best choice for the application.