The Cutting Edge of Fiber Laser Processing Technology

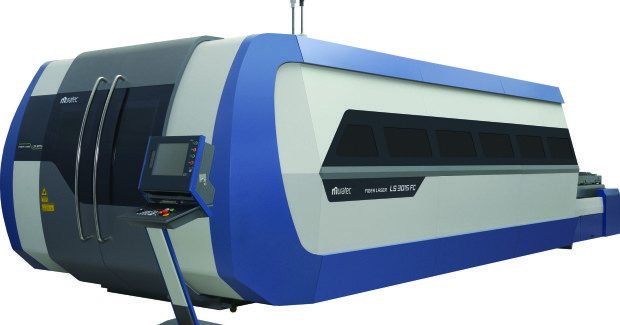

The LS3015FC Fiber Laser from Murata Machinery USA advances precision cutting with a solid state fiber laser beam that enhances the ability to process sheet metal and highly reflective materials such as copper and aluminum while significantly reducing maintenance and operating costs.

Posted: May 5, 2014

Murata Machinery USA, Inc. (Charlotte, NC), a world leader in the manufacturing and design of high-productivity metal fabrication machines and automation, offers a Fiber Laser for manufacturing operations that value high-precision cutting. The LS3015FC Fiber Laser advances precision cutting with a solid state fiber laser beam that enhances the ability to process sheet metal and highly reflective materials such as copper and aluminum while significantly reducing maintenance and operating costs.

“Today, we have installations worldwide using the LS3015FC Fiber Laser, including systems that incorporate our automated material handling systems,” said Rob Collins, the laser sales manager for Murata Machinery USA. Muratec’s advanced, proprietary technology integrates software and hardware, creating a system that maximizes the fiber laser’s cut quality, reliability, and productivity.

The LS3015FC Fiber Laser incorporates resonators from IPG, the world’s leading provider of high-powered fiber laser resonators and amplifiers. This fiber laser uses approximately one-third less power than conventional CO2 lasers which helps reduce operating costs while eliminating mirror cleaning, laser gas, and other CO2 consumables. The LS3015FC also allows operators to monitor power and gas consumption and material processing rates in real time to provide accurate operating cost analysis and true job-cost feedback.

The LS3015FC is engineered to maximize the fiber laser’s capabilities. The machine can be set to the operator’s choice of three cutting modes: high quality, for the best possible cut; economy, which reduces gas consumption and operational costs; and high-speed, for the fastest production time.

The machine features linear drives on all axes for precise, high-speed processing. A dual-pallet system preps new material and eliminates parts and scrap from falling onto the material during exchange. The cutting area of the LS3015FC is fully enclosed and is equipped with a re-circulating ventilation system that enhances safety and provides a clean working environment. The system’s rigid frame design provides high-speed, high-precision processing capabilities, with double sliding doors that provide 53 in of open access.

The Muratec-designed MVHS laser output control system helps maximize the potential of the LS3015FC. This proprietary Muratec system adjusts to changes in the laser’s output within milliseconds to promote high-quality cutting. A beam-monitoring system oversees machine stability and optics to optimize cutting conditions, extend productivity, and avoid downtime. Its light-monitoring system helps prevent reflected light that could damage the laser and continually monitors for processing parameters outside of the normal range.

If abnormal cutting parameters are detected, the machine will stop processing to avoid damage to the machine or wasted material. The fiber beam output control also produces high-quality marking for adding legible part numbers and reference marks.

Two additional monitoring and programming systems help operators further optimize the performance of the Muratec LS3015FC. The ProcessNet Monitor i software system monitors the laser’s operating conditions and power consumption. This data can be obtained remotely from a PC or mobile device connected to the system’s network and can be used to improve productivity and cost analysis.

An automatic programming system also helps improve operator efficiency and provides consistent, high-quality production. The entire system is supplemented by Muratec’s efficient, user–friendly, automated material handling systems, which are engineered to provide a stable, prolonged production cycle and help ensure maximum productivity.

Murata Machinery USA is a subsidiary of Murata Machinery Ltd. (Kyoto, Japan). From its headquarters in Charlotte, the company specializes in applications, service and sales of turret punch presses, fiber lasers and automation for those machines. Its Fabrication business unit, formerly Murata Wiedemann, supplies mechanical and servo-driven turret punch presses.

The Muratec dealer network throughout the United States, Canada and Mexico also distributes and services a complete line of turret punch presses, automated stockers, loaders, and sorting equipment.

Murata Machinery USA, Inc., 2120 Queen City Drive, Charlotte, NC 28208, 704-875-9280, [email protected], www.fiberlasermachines.com.