A 90-year Evolution from Hupmobile to High-Tech

From selling engine service tools out of the back of the Hupmobile in 1924 to the development of a basic honing device, Sunnen Products is today the world’s largest vertically integrated manufacturer of precision honing systems.

Posted: May 7, 2014

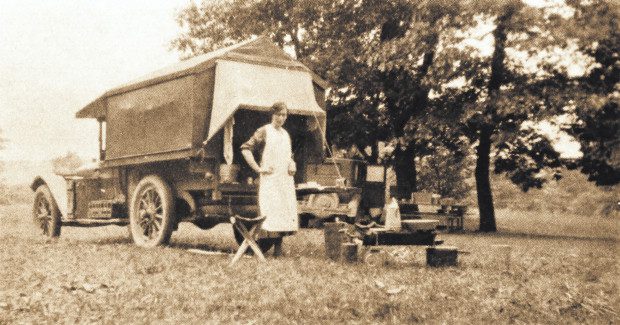

Founder Joe Sunnen’s quest to sell his honing inventions started 90 years ago with cross country sales calls made from the back of his “RV,” a 1916 Hupmobile. Today, his technology has evolved and is used worldwide to make energy exploration equipment, chain saws, aerospace components, gears, fuel injectors, fluid-power components and more. And Joe’s Hupmobile still has a place of honor in St. Louis.

Joseph Sunnen’s entrepreneurial spirit drove him to start a “mobile” business, selling his engine servicing tools out of the back of his Hupmobile truck in 1924. Early success led him to develop and patent his manual cylinder hone for auto garages. Decades later, his basic honing device has been evolved into a highly capable CNC machining process by the company he founded.

Sunnen Products Company (St. Louis, MO) is now the world’s largest vertically integrated manufacturer of precision honing systems, employing more than 650 people at 11 worldwide facilities and holding dozens of technology patents.

“As we celebrate our ninetieth anniversary, my grandfather would be proud to see that his spirit of innovation lives on in our drive to develop new products and techniques,” said Matthew Sunnen Kreider, the company president. “The Hupmobile is still on display at our St. Louis headquarters, and it reminds us not only of where we came from, but also what we can accomplish.”

What’s honing all about?

Automotive, marine and air race winners learned in the 1930s that their engines got a nice performance boost from precisely sized and finished cylinder bores made with Sunnen hones. Today, pressure for more speed, power and accuracy – with lower noise, emissions and fewer maintenance problems is leading manufacturers to use these honing systems for an ever-expanding range of products, in more industries than ever before.

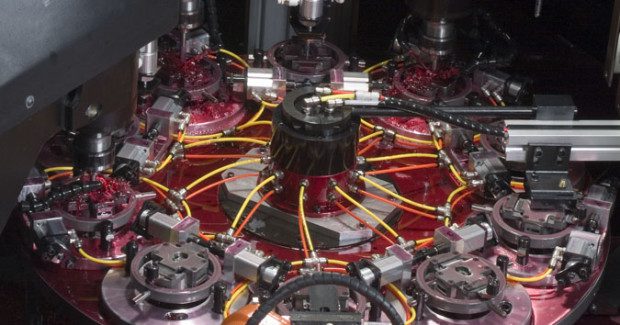

The company’s latest generation of automated honing systems provides a unique capability to control hole size with accuracy of ten millionths of an inch (0.000010 in/0.25 µm), correct geometric (shape) errors in the bore, and produce a specific surface finish to enhance lubrication and sealing properties.

The result is gearboxes and transmissions that run quieter, smoother and longer. Hydraulic systems that are more precise, responsive, efficient and leak-resistant. Chainsaws and weed trimmers that deliver higher power densities with lower emissions, and firearms that are more accurate and easier to clean.

Sunnen controls all R&D, manufacturing, service and support of its products, including specialized abrasives and tooling. This allows development of end-to-end processing systems that are custom designed and single-sourced to ensure they meet customers’ required quality and production levels. In addition to its U.S. headquarters, Sunnen has operations in Switzerland, France, Italy, the U.K., China, Russia, Brazil, Belgium, the Czech Republic, and Poland.