ITAMCO Engineer Wins Prize for Google Glass Application

Joel Neidig has been awarded a $75,000 prize for his research project titled “Expanding Manufacturing’s Vision: MTConnect® and Google Glass.”

Posted: May 6, 2014

Joel Neidig, an engineer at Indiana Gear (Plymouth, IN), (a division of ITAMCO), has been awarded a $75,000 prize for his research project titled “Expanding Manufacturing’s Vision: MTConnect® and Google Glass.”

Neidig’s winning project was his contribution to the MTConnect Challenge 2. The National Center for Defense Manufacturing and Machining (NCDMM), the Office of the Secretary of Defense (OSD), Defense-wide Manufacturing Science and Technology (DMS&T), the Association for Manufacturing Technology (AMT) and the U.S. Army Benét Labs sponsored the contest.

Participants were asked to develop innovative and unique software applications using the MTConnect standard that could be easily adopted by manufacturing enterprises, especially lower-tier producers. MTConnect is an open, royalty-free set of communication standards intended to foster greater interoperability and information sharing between manufacturing equipment, devices, and software applications.

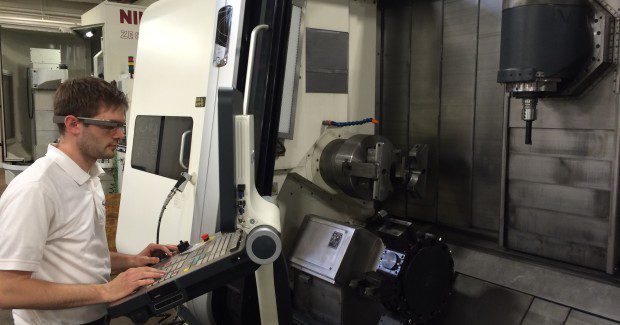

Neidig coupled MTConnect functionality with Google Glass — a camera, touchpad, microphone, email and Internet connection built into a spectacle frame. Neidig’s application, called the MTConnect Glassware app, will reveal a view of the manufacturing process that has never been seen before. The app user will be liberated from laptops and hand-held smart devices and be able to travel the entire shop floor, gathering and sharing machine data provided by MTConnect, and accessing the Internet for more information.

“We’re using the MTConnect Glassware app on our shop floor at Indiana Gear and have received inquires from companies that want a customized solution. We plan to use the prize money to develop the next generation of the app which will be available in safety glasses,” said Neidig.

The award-winning product benefits every department in a manufacturing facility, from the shop floor to the management suite. Getting and sharing information will be as intuitive and non-threatening as using a smartphone or playing a video game, but glasses do not distract from a task like handheld devices.

For example, a new machine operator watches YouTube training videos while at the machine, supplementing his training program. A machine operator sends an email to the maintenance staff as soon as he sees a problem. The chief executive officer travels the shop floor, getting accurate real-time machine data and comparing it to the company’s accounting, quality control, sales and engineering data.Project managers evaluate workflow and machine readiness before scheduling future work.

They will access 100 percent accurate data and share information with their customers to ensure smooth delivery between vendors. The maintenance staff becomes even more astute at monitoring machines and they respond quicker to problems while developing stronger preventative maintenance programs.

With Google Glass, they can “see” instruction manuals overlaid on the equipment when installing or repairing machinery. The sales staff provides guided Google Glass tours, impressing prospects with the capabilities of the facility and helping them visualize the final product.

A demonstration of the MTConnect Glassware app is available here.