Dual Tube Cutting and Finishing in One Setup

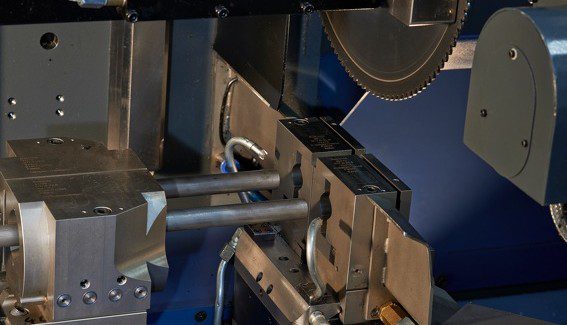

Equipped with a specially-designed twin machining head that fits onto the standard head, the ACS® + CFMtwin from Rattunde can cut two tube or bar sections simultaneously, then machines both ends of both workpieces, also simultaneously.

Posted: May 5, 2014

Rattunde Corporation (Grand Rapids, MI), a German-based manufacturer of finished length tube and solid bar production, introduces the ACS® + CFMtwin machine, the newest member in the company’s family of tube production systems. Equipped with a specially-designed twin machining head that fits onto the standard head, this machine can cut two tube or bar sections simultaneously, then machines both ends of both workpieces, also simultaneously.

This system can produce up to 5,000 finished pieces per hour. The option also exists for single tube or bar production on the same machine. The ACS® + CFMtwin machine, when in twin mode, can process two workpieces of 10 mm to 41.5 mm OD each into finished lengths from 10 mm to 1,500 mm. For example: 21 mm OD x 3.5 mm wall x 45 mm length cut from a 6.5 m mill length of stock material, based on carbon steel. When the twin head is removed, the standard machining head can process a single workpiece up to 105 mm OD.

In addition to the twin workpiece processing, this machine offers the OEM or production house all the capabilities found on the ACS® family of tube and bar production systems, including secondary brush deburring, end machining (chamfering and facing), inspection, washing, drying and robotic packaging.

The entire machine and all auxiliary workstations are motion-controlled by CNC from a single operator station for maximum efficiency. The ACS® + CFMtwin is built on the same platform as the existing and popular ACS® + CFM and ACS + CFMcurve systems.

Other standard features on this machine include data management on all workpiece parameters (approximately 10,000 workpieces), data logging of every part produced for full part traceability, material lead and end edge detection for minimized crop cut and tag end. All operating limits are set from the control panel, with continuous tool break monitoring for the saw blade and all cutting tools.

Even when processing in twin mode, the setup time for a new job can be under 15 minutes, according to Rattunde engineering. Alec Banish, the director of business development at the company, states, “This machine clearly gives us a decided advantage in the market for high-production requirements. Plus, with the standard machining head still in place on the machine, the ACS® + CFMtwin can be a highly flexible, adaptable production system for many types of manufacturing operations as well as a wide variety of end product producers.”

Because the machine offers essentially double the production in the same machine footprint, up to 40 percent energy savings have been documented on a 2 5mm OD x 3 mm wall x 42 mm long piece from a stock length of 6 m in a typical batch count of 45,000.

Rattunde Corporation, 4980 Kendrick Street SE, Grand Rapids, MI 49512, 616-940-3340, Fax: 616-940-2771, [email protected], www.rattunde-corp.com.