Boost Workhorse Press Brake Productivity

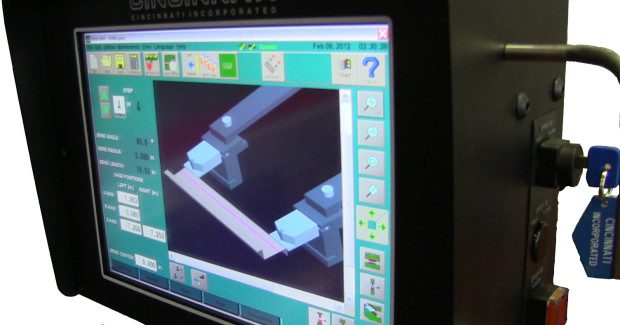

Touchscreen control and advanced bend simulation software from Cincinnati Incorporated enables 3D rotational viewing of part shape and gage fingers to be retrofitted to the company’s Autoform, Formaster, Formaster II, CB, CBII and AutoShape press brakes.

Posted: May 7, 2014

Cincinnati Incorporated (Harrison, OH) makes the productivity advantages of its latest touchscreen control and bend simulation software available to customers with popular vintage model press brakes.

The control and advanced software, which enable 3D rotational viewing of part shape and gage fingers, can be retrofitted to the company’s Autoform, Formaster, Formaster II, CB, CBII and AutoShape press brakes. The control aids operators with automatic bend simulations, graphic displays of parts before and after the bend, part orientation, setup notes and a tool library. It can access jobs from its high-capacity internal flash drive, USB or Ethernet. New part programs are easily created on the control or by using the optional offline Bend Simulation software.

“These press brakes are workhorses and are still very durable, very accurate and have many decades of use ahead of them,” said Mike Seall, the vice president of sales and service for Cincinnati Incorporated. “Controls, like computers, get outdated quickly so this is an easy, affordable way to stay current and be more productive without having to purchase a new press brake.”

The powerful, user-friendly control reduces programming and setup time through fast data entry via the touchscreen interface with large target buttons. Job setup pages display tool names and locations, segment lengths, and operator notes to further reduce setup time and ensure important instructions are displayed each time a job is recalled. After selecting the bend sequence and tools from the graphical tool library, part programs are created with one touch. Automatic Gage Allowance calculation reduces trial and error at the machine.

http://youtu.be/Y4mfxb2QCSY

A webinar on Programming a Cincinnati Press Brake with Graphics.

The new control also allows users the option of purchasing Bend Simulation Software that includes CAD file import, 3D forming simulations and automatic flat blank calculation. The software also allows for off-line programming for increased machine utilization, and checks for part interference to reduce handling errors and scrap. Optional Unfolder software allows for easy part importation from a solid model to the Bend Simulation software.

Control upgrades are conducted in the field by Cincinnati service representatives using the existing pendant arm and enclosure. A limited Planned Maintenance Service inspection, control demonstration and one-year parts and labor warranty are all included in the upgrade. Cincinnati’s technical support staff can provide remote support via Team Viewer software if the control is networked to the internet.

Cincinnati Incorporated, 7420 Kilby Road, Harrison, OH 45030-8915, 513-235-1399, Fax: 513-367-7552, [email protected], www.e-ci.com.