ERW Pipe Ovality Measurement

The Profile360 In-Line Profile Measurement System from Starrett-Bytewise automatically measures pipe diameter and ovality for ERW pipe from 6 in up to 24 in OD at two locations: in-line before cutting, and in final inspection.

Posted: April 2, 2014

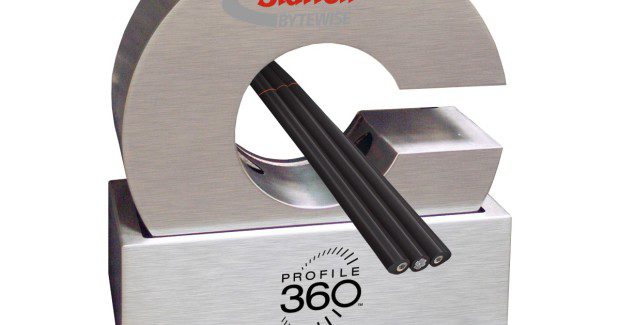

Starrett-Bytewise Measurement Systems (Columbus, GA), a global leader in on-line profile measurement systems, is pleased to announce the introduction of a new size of the Profile360TM In-Line Profile Measurement System to serve the oil & gas pipe manufacturing market. Profile360-600 automatically measures pipe diameter and ovality for ERW pipe from 6 in up to 24 in OD at two locations: in-line before cutting, and in final inspection.

Profile360 utilizes non-contacting CrossCheck Line-Laser Sensor Technology with no moving parts to deliver the highest system reliability. The system is sealed and temperature controlled for tough environments. A single measurement cycle instantaneously acquires about 5,000 data points in-plane for a 24 in pipe and can report up to 180 diameter values, one per degree. For final inspection the software displays maximum and minimum OD, ovality magnitude and angle at positions along the body and at each end.

First introduced in 2002 and now in its third design generation, Profile360TM is in use monitoring key dimensions in continuous complex profiles such as rubber, plastic, and wood-plastic composite extrusions, roll-formed metal profiles, profiled wire, and now oil & gas pipe.

An overview of Starrett Bytewise Profile360 Laser In-Line Inspection system.

Profile360 has gained popularity as an alternative to periodic off-line checking because it assures 100 percent inspection with no operator required to prepare samples, measure, and record the data. Profile360 provides a precise and automated quality audit trail for all measurements. It can also alarm for operators to intervene any time key measurement parameters go near their control limits. Users report reduced cost of scrap, improved quality, improved yield, and faster startups.