Breathe New Life Into New and Existing CMMs

By retrofitting a manual CMM to run Verisurf software, a shop adds additional functionality and productivity features that are quickly becoming requirements of manufacturing and quality engineers.

Posted: April 30, 2014

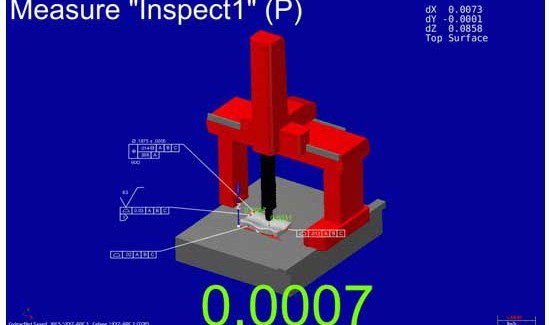

Verisurf Software, Inc. (Anaheim, CA) offers complete manual CMM retrofits that transform any manual CMM into a high performance 3D Model Based Inspection System by adding the power of Verisurf X6 Software and new USB communications. “Verisurf software has been powering portable CMMs for 20 years. We now offer the same ease of use and productivity for thousands of manual CMM’s, many which struggle with old, outdated or unsupported computers, interfaces and software,” said Terry Wear, the CMM business manager.

The surface plates and structures of manual CMMs are designed to last a very long time however the communications interface and operating software can become quickly outdated, lowering the devices effectiveness in today’s production environment. By retrofitting a manual CMM to run Verisurf software, a shop adds additional functionality and productivity features that are quickly becoming requirements of manufacturing and quality engineers.

- Model Based Definition/Inspection with associative GD&T read directly from CAD or create your own

- Share the same software as your portable CMMs

- Read in all native CAD formats

- Create rapid CAD alignments – With NO Iterations

- Create HTML, PDF, Excel or AS9102 reports including InspectionXpert

- Easily create real time display of complex profile deviations

- Digitize, reverse engineer and create solid models

- Operate in Windows 7 32 bit or 64 bit

- Use hard probes for digitizing and scanning

The Verisurf Retrofit of the CMM comes complete with a new USB interface along with Verisurf software configured to the customer’s specific requirements. Any necessary mechanical adjustments and complete geometric compensation are completed by Verisurf certified technicians. A Calibration Certificate is provided with the new verified accuracy of the CMM.

Verisurf X6 Software configurations are customized to each customer’s specific application and supported by Verisurf metrology engineers:

Inspection. Verisurf software supports both modern model-based measurement techniques and traditional blue print measurement processes. Measurement includes the import of any CAD model, creation of model associative GD&T, automated alignment of 3D CAD models to physical parts and real time probe position with deviation display.

Inspection Pro. Includes the functionality of Inspection with the addition of advanced 6 degree of freedom best fitting alignment, auto inspection programming, custom color deviation plots, results ballooning and analysis reporting.

Reverse Engineering. Digitize parts directly into CAD. Create, import, filter and edit point clouds. Create, import and edit STL mesh surfaces with hole filling, slicing, feature recognition and auto surfacing. Create and edit NURB surfaces including extruded, revolved and lofted surfaces. Create and edit CAD features including planes, holes, and pockets.

Inspection Pro & Reverse Engineering. Bundles all the functionality of Inspection Pro and Reverse Engineering.