A Focused Look at Specialized Tooling

How do you find out if a specialized tooling solution is right for you?

Posted: April 22, 2014

Nearly every sheet metal fabricator has a bending machine, whether it is a basic manual forming machine or a fully loaded CNC press brake with all the bells and whistles. These machines are typically used for one thing – taking a flat cut part and turning it into a final, three-dimensional product.

But what else can your operator create on a press brake that might save time and money by eliminating secondary processes further down the production line? Here we explore some of the different specialized tooling applications that are available for bending machines today, and how they can help boost business.

SPECIALIZED TOOLING

The results of specialized tooling can sometimes be achieved without adding new tooling to the shop. An example of this is achieved by combining horn tools and extensions. By taking two horn tools and putting the “horns” together, you can create a simple window tool that allows you to bend more complex geometries without having to create custom tooling.

Tool height extensions achieve the same result when they are added alongside a larger piece of tooling. These two arrangements create a simple window tool make it easier to bend parts with a larger return flange that would otherwise run into your tooling setup.

WingBend or pacman dies are common specialized tools which allow an operator to bend cosmetic materials without scratching. They are often more reliable than die tape which wears out quickly and may not yield the result you need.

A demonstration and overview of the TruBend 3000 series of press brakes.

A WingBend tool allows you to virtually eliminate part marking that result from the shoulders of your die, scarring the material. The tool also prevents a part with a very short flange length from falling into the die during the bending process. In addition, the WingBend tool also supports part features and prevents them from becoming distorted when the bend line is close to a hole or other feature.

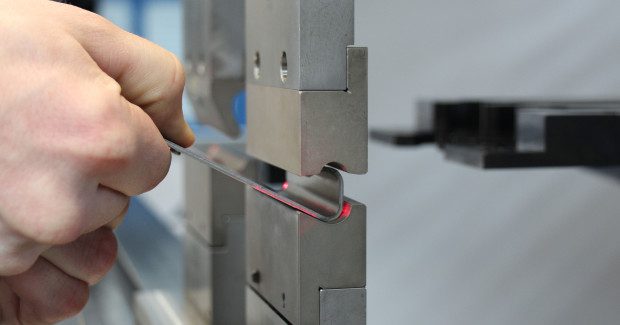

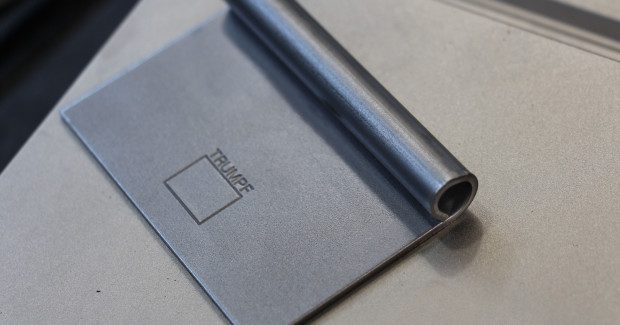

More complex examples of specialized tooling include those designed to create hinges, louvers, and countersinks. These special tools can be placed as part of the normal setup used to create the finished part. Adding value-added features to the part while it is being bent saves the shop from unnecessary secondary handling later on. Reducing part handling at any stage increases the overall effectiveness of your shop.

Sometimes, one new tool can conquer multiple problems in your shop. For example, if a part requires a custom tool, and that part comes in multiple profile lengths, you may be able to create one tool that will work for all the different profiles. One smartly designed tool may eliminate several tools, reducing the initial cost of the specialized solution.

Regardless of the tooling selected, you should look to create setups that only require a few stations so you can add a station with customized tooling and eliminate secondary handling.

PROGRAMMING WITH SPECIALIZED TOOLING

Depending on the machine you’re using on the shop floor, specialized tools may require offline programming. Machine controls with the latest technology now enable an operator to program special tools and the bend sequences right on the control. For those machines without high-tech controllers, offline programming is required.

Typically, the tooling manufacturer will send a company the profile of the tool so it can be imported directly into the programming software. Alternatively, you create in your own profile in 3D modeling software and then import a .dxf file into the machine.

Another value-added feature of offline programming is the ability to prove out your program graphically before it is run on the machine. This enables the programmer to verify that the part will fit through the window tool that was created, or if there will be enough tonnage to create that louver you desire. Questions such as these can be answered to prove out your newly customized tooling without running a test bend or creating scrap.

So how do you find out if a specialized tooling solution is right for you? Talk to your operators and find out what parts they have trouble producing and why. Also consider the path your parts take after they are formed to see if there’s an operation that can be created on the press brake to eliminate extra part handling. Any processes that can be consolidated will improve your part flow and reduce the cost per part. Then consult with a tooling manufacturer to help you create a custom solution with your prints and applications in mind.

Once they design and manufacture a tooling solution, they will create a sample tool to make sure it generates the desired result. Chances are, a custom tooling solution may help solve the problem, and the investment in the tool will be far less than the value of the scrap that your operators are already producing.