360 Degree Smart Inline Measurement Solutions

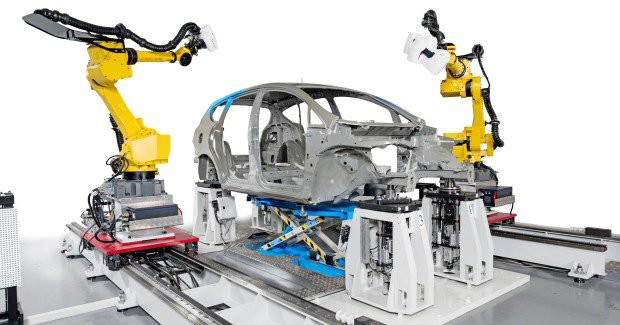

The 360° Smart Inline Measurement Solutions inspection cell from Hexagon Metrology enables full surface inspection and critical features measurement of up to 100 percent of the produced car bodies, parts and sub-assemblies – all within production cycle time.

Posted: April 2, 2014

Hexagon Metrology, Inc. (North Kingstown, RI) launched their 360° Smart Inline Measurement Solutions (360° SIMS), a family of measurement solutions that can be fully integrated into demanding automotive production lines to serve manufacturers during launch, ramp-up and ongoing production.

They enable full surface inspection and critical features measurement of up to 100 percent of the produced car bodies, parts and sub-assemblies within production cycle time. By leveraging its reliable metrology methods, innovative software and sensor technologies, the company has created an advanced means of process control for a comprehensive understanding of quality.

360° SIMS installations are adapted to their respective environment and target industry applications. Installations typically include shop floor-proven white light area measurement sensors and powerful point cloud-based software tools. Using a simple touchscreen interface, operators with basic training can supervise the measurement process, easily visualize results and identify root cause for quality concerns.

“With our 360° Smart Inline Measurement Solutions, we offer our automotive customers a next-generation system designed to answer the growing need for insightful and actionable information to accelerate production launches and monitor quality,” said Giacomo Barilà, the head of Hexagon Metrology’s automated solutions. “It is a huge step towards the digital factory of tomorrow, and integrates our most powerful offering. We’ve created a fully automated high-speed system that provides new insights into quality for the automotive community of OEMS and tier-one suppliers.

A demonstration of the The 360° SIMS solution for automated inline, near-line and offline inspection of an automotive body in white.

“The 360° SIMS offering is added to our leading sheet metal, horizontal and gantry CMMs offering, which has been a cornerstone of automotive metrology for the past 30 years,” continued Barilà. “With this offering, we’ll continue to serve our global customers directly on their shop floor.”

The company has also released the m&h IRP40.50 miniature infrared touch probe for micro-machining applications in the North American market. The IRP40.50 is ideal for inspection in tight spaces, and was designed to address the needs of miniature machining centers.

Typical applications for the probe include micro-manufacturing in the firearms, medical, dental, additive manufacturing and electronic industries or any manufacturing which involves small parts with complex geometries and tight tolerances.

Small parts with tight tolerances are very difficult, if not impossible, to measure because there is little room in the Z-axis direction and the tool magazine. The IRP40.50 eliminates this concern and leaves enough room to measure in the Z-axis without the danger of collision. The stylus threading is M2 but allows fast probe cycles at speeds up to 2,000 mm/min.

”The IRP40.50 works with PC-DMIS NC-Gage v2.1, the revolutionary software that simplifies CNC probe operations into simple, user-friendly instructions that any operator can understand. The probe was designed to inspect and correct the machining process before a bad part can be made,” states Adrian Johnson, the business manager of in-process inspection. “The IRP40.50 is able to inspect parts that were once considered too difficult or too small to inspect on machine tools. The miniature touch probe enables in-process measurement to drastically reduce scrap and rework.”

Even with its small profile, the IRP40.50 has proven high data rate (HDR) infrared transmission. This feature guarantees that only the system’s own signals are processed, and disturbances caused by extraneous light are ignored. Newly developed electronics in this mini-probe enables them to use less energy, providing 400 hours of continuous run time. This results in the longest battery life in the industry.

The company has also launched their 7.10.7 SF, the next generation of shop floor coordinate measuring machines (CMMs) specially designed to excel in harsh industrial environments. The product line introduces significant advancements based on decades of experience, the implementation of thousands of shop floor machines, and the support of those CMMs in the field worldwide. The 7.10.7 SF offers distinctive usability enhancements aimed at making the CMM more convenient and productive for manufacturing operations. The 7.10.7SF is available immediately worldwide.

“The 7.10.7 SF is our next generation offering in the SF series, and a natural progression from the original 4.5.4 SF design and its quantum leap in CMM usability,” said Eric Bennett, a product manager of bridge CMMs from Hexagon Metrology. “The 7.10.7 SF continues the trend of pushing dimensional inspection from the quality lab to the shop floor so inspection becomes simply another operation in the manufacturing process. Our attention to detail and focus on usability has resulted in a CMM with great value and exclusive benefits for our customers.”

Other user experience improvements include fully integrated workspace lighting and message lighting. The workspace lighting feature fully illuminates the measurement volume addressing the concern that a poorly lit measurement volume is a major impediment to productivity. Message lighting on the CMM’s Z-axis cover displays the status of inspection operations on the shop floor, and eliminates the need to “baby sit” the CMM. Status lights visually indicate when the inspection process is complete, whether a part passed or failed, or if an unexpected problem occurred during the operation.

PC-DMIS Touch, an optional software feature on the SF series, features an intuitive touch screen interface that expedites measurement tasks and creates, selects and launches inspection programs. Shop floor personnel do not require CMM expertise to inspect parts using PC-DMIS, the world’s most popular metrology software. With a few selections on the touch screen, PC-DMIS Touch graphically guides users through part setup and measurement, and then produces concise, meaningful reports for immediate action. The 7.10.7 SF and PC-DMIS Touch create an attractive alternative to functional gaging on the shop floor.

Hexagon Metrology offers a comprehensive range of products and services for all industrial metrology applications in sectors such as automotive, aerospace, energy and medical. We support our customers with actionable measurement information along the complete life cycle of a product – from development and design to production, assembly and final inspection.

With more than 20 production facilities and 70 Precision Centers for service and demonstrations, and a network of over 100 distribution partners on five continents, we empower our customers to fully control their manufacturing processes, enhancing the quality of products and increasing efficiency in manufacturing plants around the world. www.hexagonmetrology.com

Hexagon Metrology is part of Hexagon AB (Stockholm, Sweden), a leading global provider of design, measurement and visualization technologies that enable customers to design, measure and position objects, and process and present data. www.hexagon.com