Stick Welding Still Has a Place in the Fabrication Industry

Many applications in the fabrication industry still require stick welding. Like other filler metals, stick electrodes are available in many types, each of which provide different mechanical properties and operate with a specific type of welding power source. Before you power up your machine and pick up your stick electrode holder, consider these basic guidelines to help simplify your stick welding experience.

Posted: March 4, 2014

With so much pressure to maintain high levels of productivity, companies today often turn to faster welding processes, such as MIG, flux-cored and even robotic welding, to remain competitive. That decision makes practical and financial sense. However, there are still many applications in the fabrication industry that require stick welding (or SMAW). The reasons for using this process vary.

Fabricators may need greater access to the weld joint (where a MIG gun won’t reach) due to a complicated configuration. Or in some cases, the process may be specified for a given welding procedure. Welding on outdoor applications also benefits from stick welding since it’s very portable — it doesn’t require external shielding gas cylinders or a wire feeder.

Like other filler metals, stick electrodes are available in many types, each of which provide different mechanical properties and operate with a specific type of welding power source. Before you power up your machine and pick up your stick electrode holder, consider these basic guidelines to help simplify your stick welding experience.

ASSESS THE BASE MATERIAL, ITS CONDITION AND INTENDED SERVICE

To ensure consistent weld integrity, it’s important to select a stick electrode that matches (or closely matches) the strength and composition of the base material. Specifically, match the minimum tensile strength of the stick electrode to the tensile strength of the base material, making sure that it also matches the type of base material.

You can identify a stick electrode’s tensile strength by referring to the first two digits of the American Welding Society (AWS; Miami, FL)) classification printed on the side of the stick electrode. For example, the number “70” on an AWS E7018 stick electrode indicates that the filler metal produces a weld bead with a minimum tensile strength of 70,000 psi and, as a result, would work well with a base material of similar tensile strength.

Look, too, at the surface condition of the base material you plan to weld. To achieve the best results, always remove excessive mill scale, rust, moisture, paint and grease. Clean base materials help prevent porosity and increase travel speeds. If cleaning the base material is not possible, consider using E6010 or E6011 stick electrodes. Both deliver a deep penetrating arc that has the ability to cut through some of these contaminants.

You should also take into consideration the service conditions that the welded parts will encounter. For instance, high-heat or low-temperature applications, particularly those subject to repetitive shock loading, can benefit from the use of a low hydrogen stick electrode with higher ductility. This type of stick electrode can help reduce the chance of weld cracking. Hydrogen content is listed as a suffix to the AWS classification, as in E7018 H8, where the H8 indicates that the stick electrode meets the AWS requirements of 8 ml of diffusible hydrogen per 100 g of weldment. In many cases, stick electrodes with this suffix offer even lower hydrogen levels than those required by AWS to bear that label.

If you’re working on critical applications such as pressure vessel or boiler fabrication, be certain to follow all welding specifications, since in most cases these will require you to use specific types of stick electrodes.

CONSIDER THE WELDING POSITION

To determine what position(s) you can use a particular stick electrode in and, therefore, which one you will need for your application, refer to the third digit in the AWS classification. Here’s how to decipher the qualified stick electrode position:

1 = flat, horizontal, vertical (up) and overhead

2 = flat and horizontal only

4 = flat, horizontal, vertical (down) and overhead

As an example, the E7018 stick electrode mentioned previously can — as indicated by the 1 — be used in the flat, horizontal, vertical (up) and overhead positions.

SELECT THE PROPER POWER SOURCE

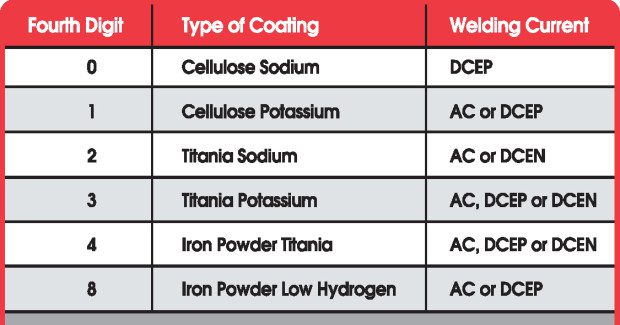

Some stick electrodes can be used with only DC (direct current) power sources while other stick electrodes are compatible with both AC (alternating current) and DC current. To determine the correct current type for a particular one, refer to the fourth digit of the AWS classification, which represents the type of coating and type of compatible welding current (see Figure 1).

The polarity of direct current you use also influences the penetration profile of the resulting weld. For example, a DCEP (direct current electrode positive) compatible stick electrode, such as an E6010, delivers deep penetration and produces an extremely tight arc. It also has the ability to “dig” through rust, oil, paint and dirt, as mentioned previously. A DCEN (direct current electrode negative) compatible stick electrode, such as an E6012, provides mild penetration and works well when bridging two joints or welding high-speed, high-current fillet welds in the horizontal position.

An AC-compatible stick electrode, such as an E6013, produces a soft arc with medium penetration and can be used to weld clean, new sheet metal.

WELDING THICK VERSUS THIN MATERIALS, AND JOINT FIT-UP

Thick materials require a stick electrode with maximum ductility and low hydrogen to prevent weld cracking. Stick electrodes with AWS classification numbers ending in 15, 16 or 18 provide excellent low-hydrogen properties and good toughness (high impact values) to accommodate for residual stress. For thin materials, a stick electrode that produces soft arcs, such as an E6013, works well. Also, smaller diameter stick electrodes tend to provide shallow penetration to help prevent burn-through on thinner materials.

It is equally important to assess the joint design and fit-up of the application. When welding a joint with a tight fit-up or one that is not beveled, use a stick electrode that provides a digging arc to ensure sufficient penetration. An E6010 or E6011 stick electrode would be sufficient. For materials with wide root openings, select a stick electrode such as an E6012 that creates a softer less digging arc, which makes it suitable for bridging gaps.

Considering these factors, along with implementing good standard welding practices, can help you overcome the challenges of selecting the correct stick electrode for your particular application. However, given the wide range of available stick electrodes, several solutions may exist for one application. If you need additional assistance with stick electrode selection, your local welding supply distributor or a filler metal manufacturer can serve as an excellent resource.