Smart Honing Lifts Business for Aerospace Hydraulic Pumps

This second generation machining business is using a new technology that makes a 60 millionths tolerance look generous. No kidding.

Posted: March 5, 2014

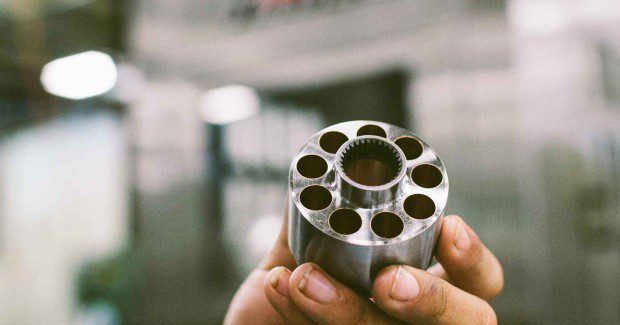

“We don’t believe it!” is how experienced machinists reacted to their first encounter with a machine tool that had produced nine bores per part with only 0.000020 in (0.5 µm) variation, all day long, with essentially no operator attention. That is 2.21 Cpk process capability, a game changing technology in a shop like Waltz Brothers Inc. (Wheeling, IL), a precision grinding and machining operation where these parts – flight-critical hydraulic pumps – are produced by the hundreds every year.

So it was no surprise to company president Larry Waltz when his machine operator complained that no one in the shop could believe how a new SV-1015 honing system from Sunnen Products Company (St. Louis, MO) turned in this performance on its first run of production parts.

Waltz knows it’s hard to hit this tolerance window honing one bore per part, much less nine, as the shop had been doing with a standard machine. With nine opportunities to make a micron-sized mistake on an expensive workpiece, it takes great skill and many time-consuming machine/measure iterations to make these parts on a standard machine.

The new hone not only produces perfect bores, it also records its final air gaging measurements to track with each serialized part. “When I showed this new machine to a customer for whom we’d been making these parts, they were so impressed they wanted us to commit to a blanket order for all their parts for the next five years,” smiles Waltz. “In that instant, we validated our painstaking decision to adopt this technology.”

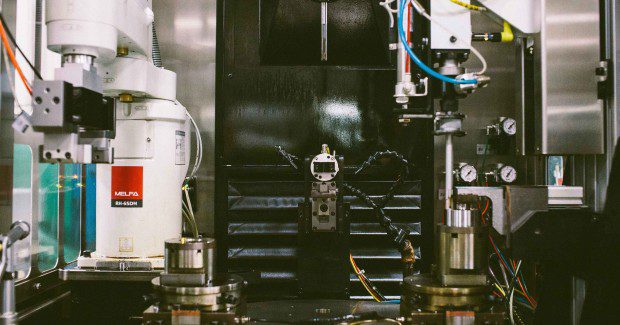

One of the keys is a patented new smart tooling technology that servo-controls the force on a honing machine’s tool feed system. It and other machine automation capabilities, such as robotic part indexing and in-process air gaging, have created a new reality at Waltz, a company that looks at machining through the eyes of a precision grinding shop.

MACHINE PARTS LIKE YOU’D HAVE TO GRIND THEM

“We’re a second generation grinding business started by my father and uncles in 1939,” says Waltz. “Our focus is close-tolerance precision parts requiring many operations that typically conclude with grinding, honing or lapping, so we added chip cutting to better control the processes upstream from grinding. Most machine shops don’t process blanks in a way that facilitates good grinding, honing or lapping results.

“For example,” he continues, “if a part is machined between centers, most shops will not be too concerned about variation in the centers, which will affect how consistently the part locates in a grinding fixture. We want to control these factors – straightness, hardness, stock allowance, etc. If grinding is only a side business to a shop’s chip cutting, they won’t look at things the way we do.”

BUSINESS NICHE IS PUMPING

One specialty at this 60-person company is the manufacture of parts that go into aerospace hydraulic actuation systems. “Piston pumps are a good niche for us,” notes Waltz. “These are the most critical parts we make. There’s great variation in materials, design details, process flow and assembly requirements, but the parts do have fundamental similarities.”

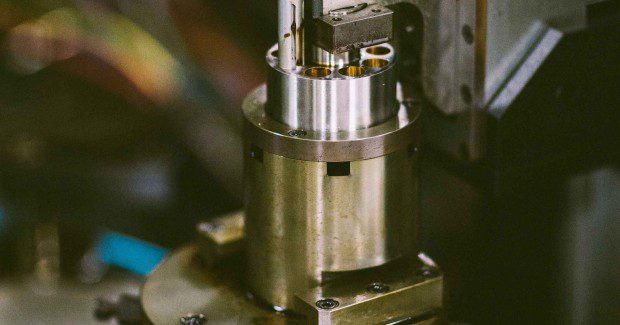

The heart of the pump, called a cylinder block or rotor, starts as a turned blank up to eight inches diameter. Then, nine circumferential piston bores from 0.1875 in to 1.5 in (4.8 mm to 38.1 mm) diameter are roughed in on a machining center, and the part may be heat treated. The piston bores are not through holes, but have small kidney-shaped slots cut through the bottom. Some designs call for heat treating, use of bronze bore liners, or bronze plating on the bottom of the part, its running face. Liners may be cast in or produced on Waltz’s screw machines, then anchored into retaining grooves with a ballizing process or swaging.

“Nine bores are common to most all pump designs,” explains Waltz. “We buy the raw stock and manufacture the cylinder block blank complete. We also manufacture several different parts that work within the final actuator assembly, including the pistons and ‘slippers.’ The pistons have a total diameter tolerance of 0.000120 in (0.003048 mm), while the bore IDs on the cylinder block have a total diameter tolerance of 0.000240 in (0.006096 mm). We must also maintain tolerances of 0.000020 in (0.5 µm) for bore roundness, 0.000040 in (1 µm) straightness, 4 µin to 8 µin (0.1 µm to 0.25 µm) Ra bore finish, and less than 3 µin (0.07 µm) surface on the pistons.”

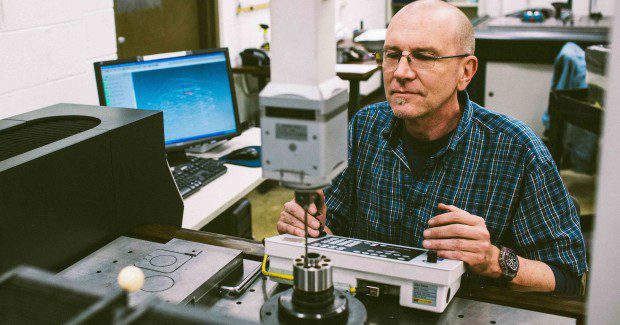

The shop uses three Zeiss CMMs that can scan the piston bores at various levels for cylindricity, too. All these parts are serialized, traceable to the material and processes used to create them.

“During prototyping, we determine where to leave needed stock on the part, but we fine tune the stock allowance over time and tweak our processes to be as efficient as possible,” states Waltz. “For example, heat treated parts are often carburized which creates only a thin layer of surface hardness at about 54 HRc. This means we want to remove as much metal as possible before hardening, so we aim for 0.0010 in to 0.0015 in (0.0254 mm to 0.0381 mm) honing stock in the bore in the hardened state. Parts with bronze bore liners are, of course, a different story.”