Next Generation OEE: Better Information = Better Shop Floor Control

Too often management invests in wiring machines to a central server for uptime and downtime reporting on the machines. These systems are relatively inexpensive and produce colorful dash boards, but may not reveal the reason for the downtime. Knowing the “who, what, why” is more important than just the “where and when.”

Posted: March 6, 2014

OEE, or Overall Equipment Effectiveness, has become an important measure for many manufacturing facilities as a way to analyze factory productivity. Without measuring OEE, manufacturers will face at the very least, misunderstandings on the shop floor, and at times, potentially damaging internal conflicts. Adopting user-friendly software to measure OEE is very effective in helping facilities to avoid daily missteps on the factory floor and increase efficiency – and profits – across the board.

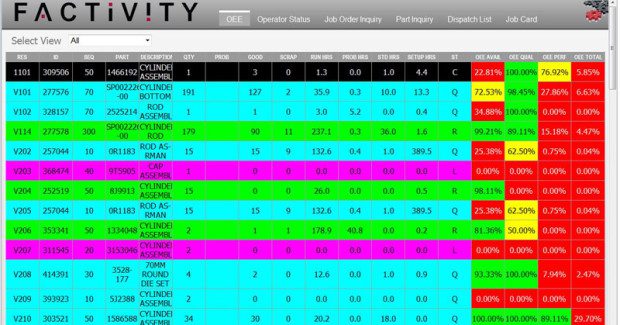

The newest generation of data collection software enables managers to view OEE through a combination of three commonly used measures: availability, performance and quality. Availability is the discovery of the amount of time factory floor assets are working on value adding the production process versus being down. Performance is how close the assets are working at their potential speed of production. Quality measures reflect the scrap as a percentage of production.

The OEE is calculated by multiplying each one of the above metrics to get a single measure represented as one total percentage. For example: 90 percent Availability along with 90 percent Performance and 90 percent Quality calculates to a 72 percent OEE (.9 x .9 x .9).

This total can be tracked from month to month, week to week, day to day – and now with new OEE measurement systems – shift to shift and minute to minute. This metric and KPI information is provided as a drill down metric starting with the Total Plant OEE. It helps upper management make decisions and can also be shared in real-time on large monitors throughout the production facility, enabling all to see these Key Performance Indicators (KPIs).

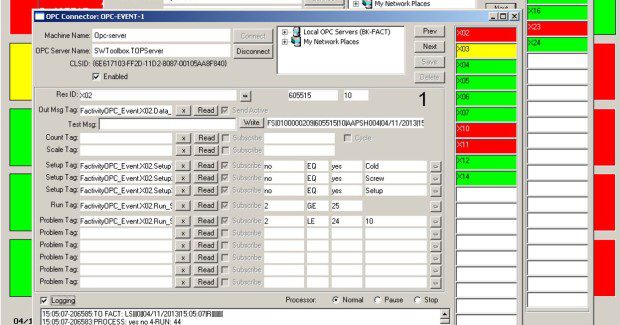

Here is an overview of the capabilities executed by the Factivity software system on the factory floor.

However, factory productivity requires more than the ability to track and view this new metric. It requires an understanding of the underlying issues that create these measures. These measures must be tied to employees, parts and reasons, not just machines, production rates and scrapped pieces.

Overall Employee Effectiveness is another measure produced by new software systems. This metric focuses on the employee as the central asset of measurement as opposed to the machine. This measure is very good in operations that have labor content as a significant factor in the successful value-add processes on the production floor. By improving factory floor operator activity, the production facility can create an improvement in the value stream.

When adopting an OEE system, make sure you understand its full capabilities. If it measures too little, and does not identify the actual underlying problems on the floor, you could be wasting your money.

Too often management will spend dollars wiring machines to a central server to get a report that shows up-time and down-time on the machines. These systems are relatively inexpensive and produce colorful dash boards. However, they may not reveal the reason for the downtime. Having a dashboard that displays ‘availability’ only shows the problem time per asset and does not have the underlying information to improve the production process.

Problems on the factory floor can be solved when the reason for the down time is determined. For example, is it driven from a breakage in the machine or due to an operator quality problem? Only through operator interaction with an easy-to-use touch screen system can you find out the details and start the process of eliminating waste. In other words, managers can use this information to make decisions to help improve their Lean Manufacturing objectives.

Don’t waste your money on a new scoreboard if you are not going to find a way to improve the team on the field.

Because the OEE measures in new software systems require little operator involvement, the system enables managers to determine the “who, what and why” – which is not captured when simply collecting the “where” and “when.” That is to say that employee accountability (who) along with reason codes (why) for scrap and down time situations (what) are more important that simply knowing which machines (where) and duration of work stoppage occurrences (when).

All the data captured is put into a database that can be seen not only in real-time but can be automatically pushed into spreadsheets for further evaluation. Drill down dash boards show plant level OEE and allow management to find the waste by digging into the details of availability, performance and quality. Management has better shop floor control and can make more informed decisions.

When measuring performance, one other thing to keep in mind is to make sure your team finds a production rate that is accepted or dictated as the basis of comparison. This can be the standard time found in the ERP system, the optimum rate established by engineering or maximum rate offered up by the equipment manufacturer.

The newest OEE measurement systems are each customized to measure exactly what the manufacturer needs to view. It’s not a cookie-cutter system. It’s built to suit the individual needs of each unique plant floor.