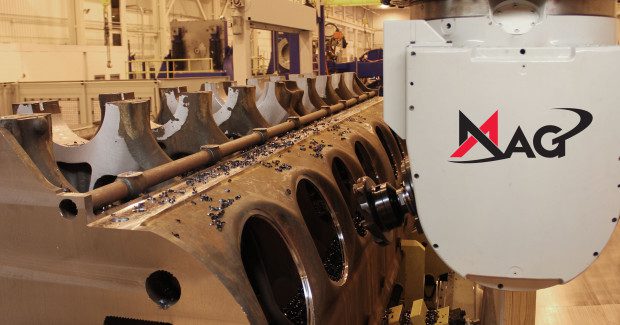

Giant Portal Mill Produces Large Diesel Engines and Other Massive Parts

The U6 universal machining center from MAG/Fives Machining is engineered for lean manufacturing of large complex-geometry parts, with 5-axis machining and contouring capabilities that are ideal for heavy cuts in large cast iron, steel, Inconel or titanium parts used in aerospace, off-road, energy, marine and mining equipment.

Posted: March 14, 2014

The giant 6-axis U6 bridge-type portal mill from MAG/Fives Machining Systems (Hebron, KY) weighs nearly 154 MT (170 tons) and is outfitted with five interchangeable cutting heads, including two custom designs to allow five-sided machining on oversized diesel engine blocks and industrial components.

Equipped to deliver up to 74.5 kW (100 hp) into the cut, the machine can complete all six sides of a 5,900 kg (13,000 lb), 16- or 20-cylinder diesel engine block in just three setups in a total time of about 30 hours. This turnkey solution from MAG includes the machine, special spindle heads, cutting tools, part programs and workholding fixture.

This particular machine tool has a working range of 13 m x 2.6 m x 1 m x 1.25 m (X-Y-W-Z), with speeds up to 20 m/min (787 ipm) and linear-axis repeatability of 0.01 mm (0.0004 in). The W+Z axes combined deliver a programmable vertical range of 2.25 m (7.3 ft) for deep reach into or around parts.

The machine is configured with a two-table system to transfer workpieces in and out of the cutting zone, enabling it to cut one part, while a second is being setup or unloaded off line. This allows parts to be machined in sets of two, using the five spindle heads and a full complement of operations including milling, facing, boring, drilling, tapping and specialty serration milling. The five spindle heads are changed automatically for maximum efficiency and minimal cycle time.

http://youtu.be/ukhRmjao6L4

An overview of how the U6 Series adjustable crossrail portal mill raises the bar for oversize-part machining. A programmable crossrail and robust design allow for extra-large part processing with minimum ram extension and heavy-duty cutting performance making it ideal for machining cast iron, steel, titanium, inconel, forgings, castings or large weldments. The U6 Series is available in moveable-table (bridge-type) and moveable-gantry (rail-type) platforms. The machine’s modular design accommodates a wide range of part size and shape requirements for aerospace agriculture, construction, die-mold, energy, industrial equipment, marine, rail, and mining equipment.

This machine is the newest and most advanced design in its class, utilizing linear way technology and all-electric drives for speed, accuracy and energy efficiency. It is whisper quiet, with proven dynamic stiffness during sustained-power qualification tests. It will produce the parts in less time, at a lower cost, when all the high-efficiency features are applied, giving the shop a competitive advantage.

The U6 universal machining center is engineered for lean manufacturing of large complex-geometry parts. Its 5-axis machining and contouring capabilities minimize downtime, part reorientations and set-ups. The machine’s robust construction makes it ideal for heavy cuts in large cast iron, steel, Inconel or titanium parts encountered in aerospace, off-road, energy, marine and mining equipment.

Its energy-efficient all-electric design eliminates hydraulic noise and maintenance issues, particularly compared to older-style, hydrostatic guideways. Replaceable low-friction linear guideways improve axis responsiveness and help reduce energy consumption. Available in a bridge or traveling gantry design, the U6 can be configured with a crossrail (Y-axis) up to 9 m (29.5 ft), while the adjustable W-axis (vertical crossrail movement) provides up to 5 m (16.4 ft) additional travel to complement up to 2.5 m (8.2 ft) of Z-axis range.

The maximum 7.5 m (24.6 ft) programmable vertical range of the machine (W+Z axes) gives it the capacity to machine, or maneuver over, tall or oddly shaped workpieces. The design allows the Y-axis rail to be positioned close to the part for machining with minimal Z-axis extension and maximum stiffness for tight accuracy.

As options, the U6 is offered with a choice of 1 m, 1.5 m, 2 m or 2.5 m Z-axis ram travel for best fit to processing needs. The U6B bridge-type machine can be equipped with an optional X-axis pallet shuttle system for cellular processing with single or multiple machines. It is available with a broad range of table and pallet shuttle systems.

The U6R rail-type traveling gantry design offers unlimited X-axis travel, and is expandable to fit the application. The U6 can be outfitted with a range of high-torque or high-speed spindles, up to 74.5 kW (100 hp) and up to 24,000 rpm, choice of tapers, and vertical, horizontal or 5-axis head configurations to cover the spectrum of machining requirements.

Automatic head exchanges are programmable, fully automated and accomplished in about one minute. The C-axis option is built into the Z-axis ram and is offered 360 deg continuous rotation to keep the spindle in-cut without running out of C-axis travel or waiting for unwind. Custom head configurations are also available.

Fives Machining Systems, 1780 Worldwide Boulevard, Hebron, KY 41048, 800-934 0735, www.fivesmsi.com.