Less Is More

As automation and multi-axis robot applications sweep through the shop floor, the functions of cable and hoses become critical to overall equipment performance. At first glance, managing cables and hoses may seem simple. But in reality, underestimating cable management can be a big time mistake. Guest columnist Don Nester of igus explains why this has become such an important part of any well-functioning robot.

Posted: March 4, 2014

Cable management has come into the limelight more and more because machine reliability has increased dramatically in recent years, even though robots have grown more complex. However, the methods used to attach and guide cables have not quite followed suit. Since the 1960s, cable management on robots hasn’t changed significantly and, in fact, is often overlooked altogether. Managing cables and hoses may seem simple, but in reality it is an important part to of any well-functioning robot.

Most experts agree one of the top blunders designers make is underestimating cable-management issues. For instance, during a conference hosted by the Robotic Industries Association (RIA; Ann Arbor, MI), a group of leading system integrators cited cable issues as the number one reason for downtime in robotics cells. Headaches range from tangled and corkscrewed cables to complete breaks that cause downtime, lost revenue, and damaged reputations.

NEW THINKING

Currently used systems try to keep the cables static, while everything operating around them is dynamic. In essence, using one, long restrictive cable package prevents movement in sync with the robot. Restrictions stress cables, which accelerates failure. Often, technicians severely bind cables with excessive dress packs (protective coverings on cables and hose), cable ties, and even duct tape. The goal might be to minimize tangling and interference with the machine, but instead these techniques actually causes corkscrewing and failure.

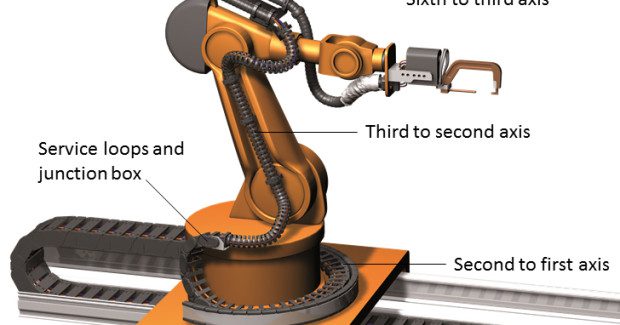

Instead, engineers need to consider a six-axis robot as three separate segments: the sixth to third axis; the third to second axis; and the second to first axis. This breakdown is imperative to longer-lasting cables. Each cable segment should feature a minimal dress pack, strain relief with service loops, and a junction box that contains and protects the electrical connectors joining the cables. For the best results, follow the following recommendations.

A comparison between Chainflex® continuous-flex cables from igus versus so-called ‘chain-suitable’ cables.

From the sixth to third axis:

1. Use strain-relief cables (we’ll talk more about ‘long-life’ cables in an upcoming section) on the moving end (sixth axis) with a one- to two-foot service loop.

2. Protect cables and hoses with a modular, multi-axis cable carrier.

3. Segment cables at the third axis and install a junction box for quick diagnostics and cable replacement.

From the third to second axis:

1. Use strain-relief cables on the third axis with a one to two-foot service loop.

2. Use a modular, multi-axis cable carrier.

3. Segment cables and install a junction box at the second axis.

Finally, from second to first axis:

1. Strain-relief cables on the second axis with a one to two foot service loop.

2. Install a multi-axis, reverse-bend cable carrier to protect and guide cables and hoses rotating around the robot.

3. Segment cables and install a junction box at the first axis.

Segmenting the dress pack into three shorter sections prevents it from wrapping, catching, or snagging on machines, and minimizes stress on cables and hoses. This approach applies to any six-axis robot, regardless of manufacturer or application. While other fixes, such as duct tape and ties wraps, might work temporarily and cost less, in the long run properly designed dress packs reduce unnecessary downtime and maintenance costs.

ADDITIONAL TIPS

Another step that should extend cable life is to allow sufficient clearance inside the carrier for electrical cables, pneumatic hoses and tubing for other media. This compensates for relative forces between cables and hoses. Carrier suppliers typically provide this data. For instance, general rules of thumb for igus® Triflex® R carrier are:

1. Total cable and hose diameters must not exceed 60 percent of the carrier diameter.

2. Leave at least a 10 percent clearance between any two cables and hoses.

3. Cables and hoses need to move freely inside the carrier.

Safety is also a major concern within robotics cells. With the less-is-more approach, designers can let cables and hoses move freely, but not to the point where they could potentially injure workers. As six-axis robots evolve, cable-management systems need to develop along with them. Designers should consider the less-is-more approach for every robotic applications, as it eliminates cable damage, expensive maintenance and downtime.

Of course, a number of other elements, including the robot’s function, space constraints and budget also play a role. But for any combination, there is a suitable less-is-more approach that keeps vital cables away from harm’s way while enabling them to mimic the fluid movements of a six-axis robot.

CONTINUOUS-FLEX CABLES

In addition to the appropriate dress pack, it is imperative that six-axis robots use dynamic cables specifically designed for continuous flexing. Two important features to take into account are a cable’s torsion-resistance and shielding. Shielded cables face a greater risk of failure, as constant movements can easily compromise the cable jacket. Use unshielded, high-flex cables whenever possible to avoid problems.

For example, we offer our own range of robotic cables called CF Robot that include hybrid, bus, measuring system, fiber optic, motor, servo and more. All of these cables are specifically designed for and tested in applications involving high levels of torsion and ideal for use in Triflex® R cable carriers.

In contrast to conventional braided copper shields, which are counter-wound, a torsion-resistant, tin-plated copper shield sheath is used with CF Robot. The forces affected on the cable by any torsional movement are largely absorbed by sliding and buffer elements between the sheath, shield and insulation. This prevents early failure of the shield. The outer sheath material is a high-grade TPE mixture with particularly good wear properties.

If you’re working on a multi-axis robot application, consider taking a less-is-more approach to cable management. It will extend the life of your cables and hoses and improve overall performance.