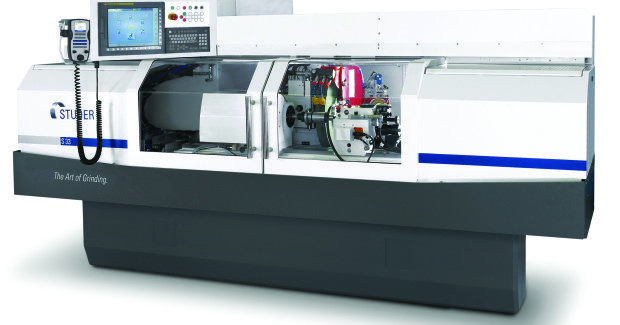

ID/OD Cylindrical Grinding for Production Lines to Small Job Shops

The flexible Studer S33 from United Grinding Technologies is an advanced high-performance CNC universal ID/OD cylindrical grinder with a modular design for quick setup and changeover, state-of-the-art digital control and drive systems and user-friendly step-by-step programming that handle a wide variety of internal and external cylindrical grinding applications.

Posted: March 26, 2014

UGT also offers the Studer S41 CNC universal cylindrical grinder, featuring outstanding technology and cost-effectiveness. The machine grinds with superior precision and at extreme metal removal rates. The longitudinal and cross slide, as well as the swivel axis for the wheelhead, feature electric direct drives, which move to the working position very swiftly and precisely.

An overview and demonstration of the capabilities of the Studer S41 CNC universal cylindrical grinding machine.

Higher precision, better surface quality, higher metal removal rates – these are the constantly increasing requirements made by the market. In addressing these requirements, the developers based the S41on a predecessor machine proven worldwide over many years, while adding a number of outstanding design features. It works more quickly and precisely, offers a broader range of applications, with production options that are highly attractive with regard to cost-effectiveness. By saving on auxiliary times, the S41 considerably shortens the cycle times of the grinding process.

The guideways of both the longitudinal slide and the cross slide are molded directly into the Granitan® S103 machine bed. To ensure that the high forces that occur during grinding with high metal removal rates are optimally absorbed into the machine bed, the guideways have a larger spacing.

The longitudinal slide (Z-axis) has a ground work table which carries the workhead and tailstock as well as additional accessories and devices. A ground T-slot over the entire length of the guideway enables optimal positioning of dressing tools. The cross slide (X-axis) supports the wheelhead. Longitudinal and cross slides are moved by linear direct drives and, with up to 66 fpm, achieve four times higher travel speeds and axis system resolutions of ten nanometers. This enables high-precision and highly efficient grinding, as well as making a huge contribution to reducing auxiliary times.

The swivel movement of the turret wheelhead (B-axis) is also by a direct drive. It swivels the turret wheelhead around three times faster (< 3 sec) and positions the new grinding wheels in a much shorter time with a positioning resolution of 0.00005 deg. The positioning is therefore twice as precise as with the predecessor machine. The elimination of the Hirth gear, which fixed the wheelhead in position on the predecessor machine, also contributes to faster positioning.

When swiveling in a new grinding wheel it is no longer necessary to lift the turret wheelhead out of the Hirth gear and then to engage it again by lowering it. The time required for fine adjustment after engaging in the Hirth gear is also saved. This new concept makes a considerable contribution to saving on auxiliary times — particularly when the workpiece grinding process requires frequent swiveling-in of different wheels. In addition to the considerable increases in working speed and precision, the S41 also has a number of advantageous characteristics which enable the user to cover an extended workpiece range, and thus a broader market range.

For instance, the height of centers on the standard version has been increased to 8.9 in. The machine is also optionally available with a height of centers of 10.8 in; this is not achieved by means of distance plates, but by making the workheads higher. The maximum distance between centers is 39.4 in on the standard machine, but a machine variant with a distance between centers of 63 in is also available. Thanks to the greater heights of centers and distances between centers, workpieces with weights of up to 551 lb can now also be machined. The machine is equipped with a hydraulically clamped tailstock for the heavier workpieces.

Up to four external grinding wheels or three internal grinding spindles enable over 30 grinding head combinations. The grinding wheels are no longer driven by belt drives, but by motor spindles. The machine can also be equipped with motor spindles for high speed grinding (HSG). Internal grinding spindles with speeds from 6,000 to 120,000 rpm can be used. Automatic balancing systems and frequency converters for each external grinding spindle allow the grinding process to be specifically matched to the respective conditions of use. Wheelhead variants are also available with a vertical spindle for grinding keyways or with a traverse grinding axis for traverse grinding of internal tapers.

Fatigue-free working and straightforward machine operation are important components for consistently high quality. For this reason, optimized ergonomics were one of the developers’ priorities. For instance, hoses and cables have largely disappeared from the work area of the machine. Grinding wheel change is performed with a single Allen wrench, and a special small crane is integrated into the machine, so that heavier grinding wheels do not have to be lifted manually.

The Fanuc 31i-A machine control with integrated PC operates with the StuderGRIND software specially developed for the grinding processes, and the StuderWIN operator interface. A 15 in touch screen and ergonomically arranged controls are available to the grinder for communication with the control system and for programming. An additional manual control unit facilitates setup of the grinding processes. The convenient electronic cut-in detection facilitates operation and contributes to increasing precision and reducing auxiliary times.

The software also contains tools for programming form and contour grinding processes, and enables offline programming of grinding processes as well as the determination of important basic cycle data to give the user a good basis to quote grinding tasks to his customers. A free-standing operating panel with adjustable height is also available.

Studer universal, external and internal grinders are supported by an expert team of grinding specialists and technicians drawing on more than 10,000 machine installations and a worldwide support and service network. United Grinding Technologies, the North American arm of the Körber-Schleifring Group and supplier of such venerable nameplates as Blohm, Ewag, Jung, Mägerle, Mikrosa, Schaudt, Studer and Walter, is a global leader in grinding technology and has built a reputation for industry-leading innovation and unparalleled service and support.

United Grinding Technologies, Inc., 510 Earl Boulevard, Miamisburg, OH, 45342, 937-847-1229, Fax: 937-859-1115, www.grinding.com.