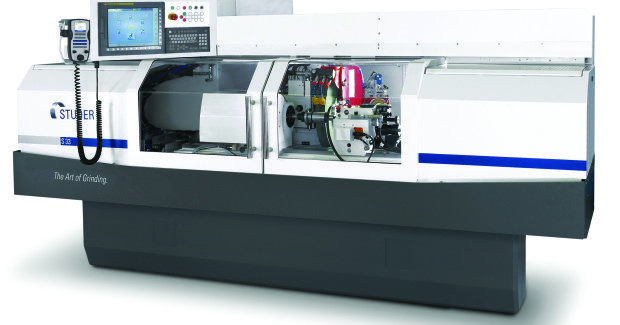

ID/OD Cylindrical Grinding for Production Lines to Small Job Shops

The flexible Studer S33 from United Grinding Technologies is an advanced high-performance CNC universal ID/OD cylindrical grinder with a modular design for quick setup and changeover, state-of-the-art digital control and drive systems and user-friendly step-by-step programming that handle a wide variety of internal and external cylindrical grinding applications.

Posted: March 26, 2014

United Grinding Technologies, Inc. (UGT; Miamisburg, OH) offers the S33, an advanced addition of its Studer line of high-performance CNC universal ID/OD cylindrical grinders. Modular design for quick setup and changeover, state-of-the-art digital control and drive systems and user-friendly step-by-step programming make the S33 a remarkably flexible solution to a wide variety of internal and external cylindrical grinding applications. From high throughput OD production lines to small-scale job shops, the S33 has the ability to reduce changeover times, speed up grinding processes and deliver consistent precision at an affordable cost.

The S33 has been enhanced and designed to take into account the specific needs of the North American market (automotive OEMs and Tier One suppliers), in that the S33 reflects the expressed desire for a machine to address internal and external applications in a single platform. Center height is 175 mm. Between-centers grinding length is either 650 mm or 1,000 mm. OD wheel size is ø 500 mm x 63 mm x ø 203 mm. Chuck capacity between centers is 80 kg to 120 kg.

The basic wheelhead can be indexed at 0 deg or 30 deg for straight and angular plunge grinding. A universal turret wheelhead swivels manually or automatically, permitting external, internal and face grinding of workpieces in a single setup. The machine features a high precision Hirth coupling B-axis with a 1 deg indexing capability. The turret head repeats in .08 arc seconds. This allows for extreme accurate ID to OD run-out and concentricity.

An overview of the capabilities of the Studer S33 CNC universal cylindrical grinding machine.

V and flat guideways are coated with abrasion-proof Granitan® S200 and provide high vibration dampening and superior rigidity. The machine base of Studer-developed Granitan® S103 delivers outstanding vibration dampening, rigidity and strength, as well as excellent chemical stability and thermal compensation.

Digital direct-drive, three-phase servomotors with 40-mm diameter pre-stressed, precision ballscrews power the X- and Z-axes. Cross slide X-axis travel is 285 mm at speeds ranging to 10,000 mm/min. Linear resolution is 0.0001 mm. Distance between slideways is 280 mm. Z-axis slide travel is up to 1,150 mm. Speed and linear resolution are respectively 20,000 mm/min and 0.0001 mm. Z-axis distance between slideways is 200 mm. Z-axis table tilts up to 8.5 deg for high-precision grinding of tapers.

Direct drive spindle turret wheelhead is powered by a 10 hp motor and has high-precision roller bearings for precise, high-resistance, maintenance-free operation. Peripheral speed up to 50 m/sec with infinitely adjustable speed control to 3,200 rpm. Workpiece spindle, with high-precision roller bearings, handles grinding between dead centers as well as live grinding with revolving spindle. Precision control permits fine adjustment of cylindricity during grinding operations to ± 40 µm. Guaranteed tolerance precision: 0.0004 mm on roundness and 0.0025 mm straightness deviation over a length of 650 mm or 1,000 mm.

The S33 features state-of-the-art Fanuc 00i-TD digital control and axis drive components. Machine operation, setup, changeover, dressing and programming of even complex parts are easily accomplished through the innovative, step-by-step Windows-based StuderWin software with graphical operator interface and 15 in color touch screen for CNC control with integrated PC, which allows operators simply to connect grinding cycles to one another and add necessary numerical values. The control then generates the machine program automatically.

Advanced manual programming in G code is of course also possible. Programming is done directly at the machine or off-line and then downloaded to the machine control. Process parameters can be changed on the fly, while the machine runs, without affecting the workpiece program. The S33 control package features proven application-specific Studer grinding cycles for diameters, shoulders (left and right), tapers (negative and positive) and contours. The control also features a technology calculator for definition of process parameters, integrated in-process gaging (optional) and integrated programming of the smartLoad system (optional).

With the recent addition of the Studer CT internal cylindrical grinding machine series, UGT has substantially increased their ID grinding capabilities. In the area of internal grinding of chucking components, the Studer CT550 sets new standards. Higher precision, better surface quality, high metal removal rates – in addressing these requirements, UGT has again set the standard with its CT550 CNC internal/universal cylindrical grinder. It works more quickly and precisely, offers a broader range of applications, with production options that are highly attractive with regard to cost-effectiveness. By saving on auxiliary times, the CT550 considerably shortens the cycle times of the grinding process.

The CT550 is a compact machine for medium-sized workpieces with up to three inline grinding spindles. The modular and flexible arrangement of spindles enables optimal dimensioning of the machine, ranging from the manufacture of individual parts as well as large-scale production. This machine also supports integrated and autonomous loading system

The Granitan® S103 machine bed provides a very solid, rigid and thermally stable CT550. The formula of this mineral casting is designed for optimal grinding operation conditions. Thus, the machine bed literally provides the integrated guide system with a stable basis for absorbing the high forces that occur during grinding. Thanks to its remarkable thermal behavior, the machine bed largely equalizes brief variations in temperature – so that the machine operates with consistently high precision even with changing ambient temperatures. Its high rigidity and excellent damping provide the basic prerequisites for outstanding surface quality of ground parts and long grinding wheel lifetimes.

Three inline modular spindles provide flexibility and optimal dimensioning to the machine. The diameter of the HF (high frequency) spindle ranges from 80 mm to 120 mm. The belt-driven spindle diameter is 80 mm. External grinding wheel is 305 mm. Axes travels are 520 mm (X) and 250 mm (Z). The manual B-axis setting angle is +1 deg / -1 deg. Workhead speed is 1,200 rpm, maximum. Load on the spindle nose, 100 kg. Center height above the table is 1,500 mm. Maximum part length, 650 mm, while the grinding length is 150 mm. Control: the intuitive, easy to use Fanuc 310i-A.