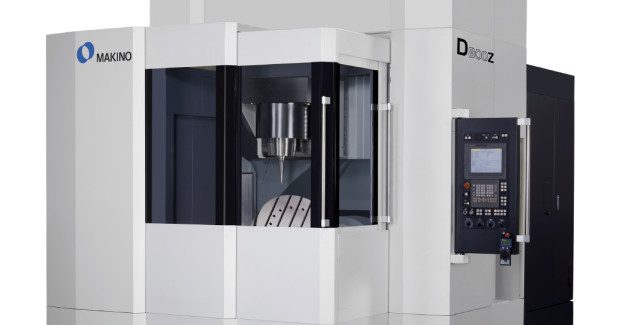

5-Axis Machining Center for Large Parts, Precision Die/Mold and Aerospace Applications

The D800Z vertical machining center from Makino handles workpieces of up to 1,000 mm in diameter and 1,200 kg in weight that can be machined in five axes, with great efficiency and fewer operations for reduced production time.

Posted: March 21, 2014

Makino offers the D800Z as part of its family of 5-axis vertical machining centers. Joining the Makino D-Series (D300 and D500), the D800Z is designed for high-performance job shops, precision parts machining, die/mold and aerospace applications.

Like the other two D-Series machines, the D800Z offers easy access to the spindle and table, a highly rigid structure for responsive cutting, outstanding surface finishes and optional automation devices. Workpieces of up to 1,000 mm in diameter and 1,200 kg in weight can be machined in five axes, with great efficiency and fewer operations for reduced production time.

“Large-part 5-axis machining presents numerous challenges, due to the size, weight and range of features found on large components,” said Bill Howard, the VMC product line manager at Makino. “This 5-axis machine provides advanced levels of sustained dynamic accuracy, achieved through technologies that are very productive, yet minimize thermal influences and maximize volumetric accuracy.”

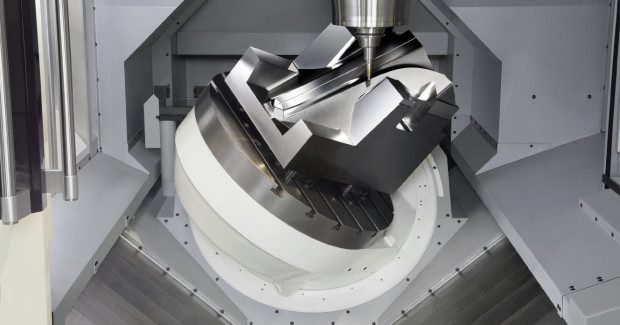

A demonstration of the capabilities of the D800Z 5-axis vertical machining center.

The 5-axis capability can be utilized in five-face milling mode to minimize setup, maximizing access to complex, multisided parts and reducing cycle times, or to address the demanding angular, blending, matching, fine-surface finishes and 3D accuracy requirements of die-and-mold components.

The integral, direct-drive motor design of the fourth and fifth axes and highly rigid supporting machine structure deliver productive speed and smooth motion, and ensure outstanding accuracy — even with large workpieces and payloads up to 1,200 kg. In addition, core-cooled ballscrews, temperature control of the direct-drive motors and massive machine structure provide renowned thermal stability that guarantees sustained accuracy over time.

The uniquely designed “Z” shape of the tilt-trunnion table ensures that the center of gravity of the table and work are always captured within the center of rotation of the B- and C-axes. Large-diameter bearings minimize table deflection and provide outstanding stiffness and rigidity, regardless of the angular and rotary position of the work. The direct-drive motor design provides the speed for productivity and precision for tight-tolerance work.

The D800Z can be configured with two different spindle combinations: D800Z (#40) and D800Z (#50). The machine (#40) offers a standard Cat #40 (or optional HSK-A63) 14,000 rpm spindle. As an option, it (#40) can also be configured with a 20,000 rpm HSK-A63 spindle.

The machine (#40) incorporates a 40 tool magazine and the D800Z (#50) offers a standard Cat #50 (or optional HSK-A100) 12,000 rpm spindle. As an option, the D800Z (#50) can also be configured with an 18,000 rpm HSK-A100 spindle. The D800Z (#50) also incorporates a 48 tool magazine.

The range of spindle offerings provides the ability to customize the machine to suit a wide variety of machining applications. Feedrates of 36,000 mm/min on the X-, Y- and Z-axes, and 18,000 deg/min (50 rpm) on the B- and X-axes ensure productivity.

Also featured is proprietary, next-generation Super Geometric Intelligence (SGI.4) software developed specifically for high-feedrate, tight-tolerance machining of complex 3D, contoured shapes involving continuous tiny blocks of NC data, which ensures production rates faster than standard CNC systems, while maintaining high accuracy.

SGI.4 helps provide the lowest cycle times and costs achievable by reducing machining cycle times on dies, complex cavities and cores, and aerospace parts by as much as 40 percent, when compared to most other control technologies.

The D800Z is equipped with a number of 5-axis features, including Tool Center Point (TCP) control, which permits programming based on the tool tip, so that tool compensation features can be applied. Further TCP developments improve the cutter path to achieve greater surface quality. Dedicated user-friendly screens are developed to simplify the overall application of 5-axis machining. Easy-to-apply functions are included to prevent interference between the spindle and trunnion during automatic operation, eliminating collisions.

This machine tool comes with a two-sided front-door design, for easy access to the spindle and table for setup purposes, and a large window, for enhanced visibility. The machine’s compact size of 3,200 mm x 5,070 mm x 3,600 mm requires less floor space, and its intelligent design facilitates maintenance activities.

The D800Z has also been designed to lower a shop’s operating costs through reduced energy consumption. To save energy costs, it features an eco mode, which turns off peripheral devices when they are not needed. The energy-saving coolant system comes with an inverter-driven coolant pump that supplies precisely the required flow rate and timing for each function. The hydraulic unit, with its accumulator, ensures zero power consumption when the pump is idle.