Characteristics of Heat Treatable vs. Non Heat Treatable Aluminum Alloys

There are certainly differences in strengths for aluminum alloys, whether they are heat-treatable or not. These different characteristics impact the final strength of the weld because these alloys differ in their chemical and metallurgical structure and in how they react during the welding process.

Posted: February 24, 2014

There are two basic types of aluminum alloys: heat-treatable and non-heat treatable. Each are widely used but their different characteristics impact the final strength of the weld, as these alloys differ in their chemical and metallurgical structure and in how they react during the welding process.

STRENGTH OF ALUMINUM ALLOYS

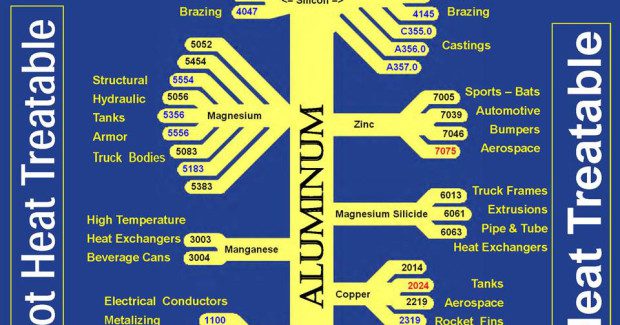

The characteristic strength of non-heat treatable aluminum alloys is initially created by alloying the aluminum with other elements. These alloys consist of the pure aluminum alloys (1xxx series), manganese alloys (3xxx series), silicon alloys (4xxx series) and magnesium alloys (5xxx series). The alloys are further strengthened through various degrees of cold working or strain hardening.

Cold working or strain hardening is accomplished by rolling, drawing through dies, stretching or similar operations where area reduction is obtained. Regulating the amount of total reduction in area of the material controls its final properties. Material subjected to a strain-hardening temper may also be given a final, elevated temperature treatment called “stabilizing,” to ensure that the final mechanical properties do not change over time.

Here is an inside look at the manufacturing processes used to produce AlcoTec aluminum welding wire.

The letter “H” followed by numbers denotes the specific condition obtained from strain hardening. The first number following the “H” indicates the basic operations used during or after strain hardening:

- H1 – Strain hardened only

- H2 – Strain hardened and partially annealed

- H3 – Strain hardened and stabilized

The second number following the “H” indicates the degree of strain hardening:

- HX2 – Quarter Hard

- HX4 – Half Hard

- HX6 – Three-Quarter Hard

- HX8 – Full Hard

- HX9 – Extra Hard

The initial strength of heat treatable aluminum alloys is also produced by the addition of alloying elements to pure aluminum. These elements include copper (2xxx series), magnesium and silicon, which is able to form the compound magnesium silicide (6xxx series), and zinc (7xxx series). When present in a given alloy, alone or in various combinations, these elements exhibit increasing solid solubility in aluminum as the temperature increases.

Because of this reaction, it is possible to produce significant additional strengthening to the heat-treatable alloys by subjecting them to an elevated thermal treatment, quenching, and, when applicable, precipitation heat-treatment known also as artificial aging.

Note: Because of additions of magnesium and or copper, there are also a number of silicon (4xxx series) alloys that are heat-treatable.

In solution heat-treatment, the material is typically heated to temperatures of 900 deg F to 1050 deg F, depending upon the alloy. This causes the alloying elements within the material to go into solid solution. Rapid quenching, usually in water, freezes or traps the alloying elements in solution, follows this process.

Precipitation heat-treatment or artificial aging is used after solution heat-treatment. This involves heating the material for a controlled time at a lower temperature (around 250 deg F to 400 deg F). This process, used after solution heat-treatment, both increases strength and stabilizes the material.

MATERIAL TYPE IMPACTS WELD

In short, the difference in transverse tensile strength of the completed groove weld is governed by the reaction of the base material to the heating and cooling cycles during the welding operation.

Generally speaking, the non-heat-treatable alloys are annealed in the heat-affected zone adjacent to the weld. This is unavoidable when arc welding, as we will reach the annealing temperature, and extended time at these temperatures is not required in order to anneal the base material.

The heat-treatable alloys are usually not fully annealed during the welding operation but are subjected to a partial anneal and over-aging process. These alloys are very susceptible to time at temperature; the higher the temperature and the longer at temperature, the more significant the loss of strength in the base material adjacent to the weld. For this reason, it is important to control the overall heat input, preheating, and interpass temperatures when welding the heat-treatable alloys.

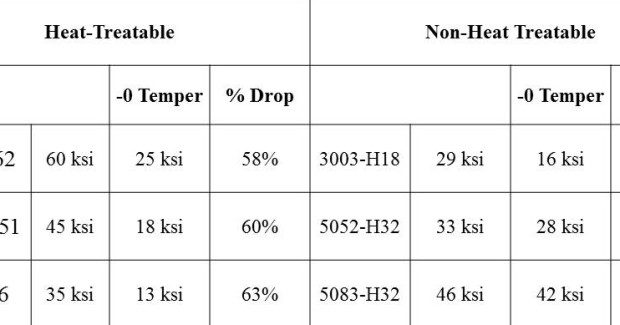

Typically, the common heat-treatable base alloys, such as 6061-T6, lose a substantial proportion of their mechanical strength after welding. For example, 6061-T6 typically has 45,000 psi tensile strength prior to welding and around 27,000 psi in the as-welded condition. One option with the heat-treatable alloys is post weld heat-treatment to return the mechanical strength to the manufactured component. If post-weld heat-treating is considered, the filler alloy’s ability to respond to the heat-treatment should be evaluated.

Most of the commonly used filler alloys will not respond to post-weld heat treatment without substantial dilution with the heat-treatable base alloy. This is not always easy to achieve and can be difficult to control consistently. For this reason, filler alloys have been developed to independently respond to heat-treatment.

As an example, filler alloy 4643 was developed for welding 6xxx series base alloys and developing high mechanical properties in the post-weld heat-treated condition. This alloy was developed by taking the well-known alloy 4043, reducing the silicon, and adding 0.10 percent to 0.30 percent magnesium, thus ensuring its ability to unquestionably respond to post-weld heat-treatment.

In conclusion, there are certainly differences in strengths for aluminum alloys whether they are heat-treatable or not. While some of the heat-treatable can develop great strengths such as the 7XXX series that can hit tensile strengths into the 70s (ksi), these are also susceptible to large drops in the HAZ (Heat Affected Zone) during welding. Many of the non-heat-treatable alloys tend to loose less strength in the HAZ. This is one of the reasons 5XXX series alloys are often used in areas where strength is required for products that require welding.

Chart 1 shows a few common alloys at their full strength, their as-welded condition strength (fully annealed condition), and the percentage drop. These values are found in the Aluminum Standards & Data published by the Aluminum Association. While some welds may not hit a complete -0 Temper during welding, it does indicate that alloys that gain their strength from cold working may be better suited for welded applications such as truck, trains, and shipbuilding.

Subscribe to learn the latest in manufacturing.