When Good Gets Better

To improve the machining of one of their key products, this leading German metalworking firm turned to a solid carbide modular milling system that yielded big gains in accuracy and productivity.

Posted: January 24, 2014

How do you make an already good machining process even better? That’s the challenge that Carl Leipold GmbH (Wolfach, Germany) set for itself. Leipold specializes in manufacturing precision parts for the automotive, electrical and building technology industries, among others.

With nearly 400 employees in four locations in Germany and the U.S., Leipold is one of the largest manufacturers in the Black Forest area and strives to maintain this position by emphasizing “quality, customer satisfaction, continuous improvement, team work and the prevention of downtime,” says production manager Robert Kern. This focus, he adds, helps the company “be better prepared for cost pressures along the entire supply chain,” and remain competitive in global markets over the long term.

Their emphasis on continuous improvement is particularly evident in their approach to more complex high volume parts where, as Kern notes, “the maximum level of precision and efficiency is required because the smallest of errors has an effect on the whole series and can cause economic problems.” The production of these parts is regularly analyzed with an eye toward achieving process improvements, often through the aid of key suppliers. Such was the case when Leipold directed its focus on a complex fuel distribution part machined from 304 series austenitic stainless steel.

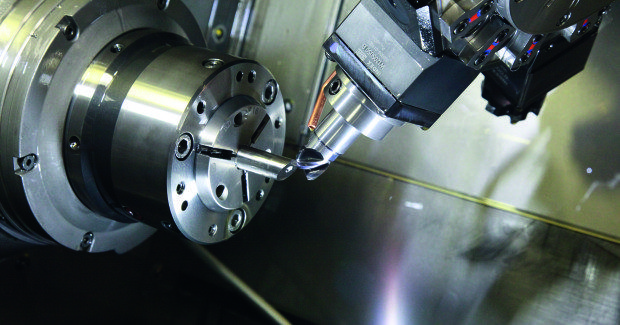

A demonstration and overview of Walter Prototyp Milling Conefit Spade solid carbide exchangeable heads.

Florian Vollmer, head of Leipold’s Technology Center, was tasked with improving the productivity and cost effectiveness of this vital machining operation. Mathias Scherer, a technical consultant from Walter AG (Tübingen, Germany), was called in to assist. A team was formed comprising specialists from Walter and Leipold to study all aspects of the operation and determine ways to optimize it. “In this case, we were striving for a high level of repeatability with fewer rejects,” says Vollmer. “Additional factors were the ability to be less labor intensive, the need for less frequent measurement and fewer tool changes. Overall we wanted a process which was more robust and stable, with a significant improvement in tool life.”

The insert-type milling cutter with three cutting edges that Leipold was using in this operation was only capable of producing 8,000 parts, after which it would be unusable. The part has a concave shaped radius that in the course of long production runs would lose its dimensional accuracy. This loss of accuracy was particularly troubling since, as Roland Braunwarth, head of CNC and multi-spindle production at Leipold explains, “This component is a ‘long runner’ that has been manufactured virtually around the clock for about two years. The highest level of precision and efficiency is essential, and so the process must function flawlessly.”

The delays resulting from the need for frequent measurements and tool changes lowered the productivity of this operation, which in turn made the part more costly to produce. Together, the joint Leipold-Walter team decided to change the tooling strategy, swapping the existing insert type milling cutter for the Walter Prototyp ConeFit™ milling system.

ConeFit is a modular solid carbide milling system that combines a solid carbide replaceable head with a steel toolholder. The cone-shaped adapter consists of a precision cone with a patented self-centering thread. The support and short taper face and the self-centering thread ensure precise and rapid tool change, and provide superior stability and accuracy. This, in turn, boosts machining accuracy. Also, thanks to its different extensions and holder variants, ConeFit can be used for virtually any machining application.

The results were convincing. “With ConeFit, the output improved even more markedly than the team had expected,” reports Braunwarth. “In addition, we accomplished a more stable process with better dimensional accuracy.”

Fridolin Steger, the Leipold technical specialist responsible for production planning, reported that the service life of the tool has increased considerably through the changes that were made. “This has significantly reduced machine downtime caused by tool changes,” explains Steger. “Machining the critical component previously required two cutting operations. Thanks to the tool changeover, one cut now is sufficient because the ConeFit system provides significantly better dimensional accuracy. The high level of rigidity also guarantees high cutting performance.”

Because of the impressive results achieved in the short term, further application areas for the ConeFit system are presently being tested and assessed at Leipold. According to Braunwarth, “We have a wide range of machine tools that this system can be used on, including our single-spindle turning centers, multi-spindle turning machines and rotary indexing tables. The ConeFit system can be used across all of our machines.

Following its successes with ConeFit, Leipold has proceeded to investigate the possibility of optimizing additional operations with other tools from the Walter product range, and joint tests in a number of areas have been encouraging in recessing, grooving and parting operations, among others.

Carl Leipold GmbH, Schiltacher Straße 5, D-77709 Wolfach, Germany, +49 7834 83950, Fax: +49 (0) 7834 / 8395 – 55, [email protected], www.leipold.com.

Walter AG, Derendinger Straße 53, 72072 Tübingen, Germany, +49 7071-701-0, Fax: +49 7071-701-212; Walter USA, LLC, N22 W23855 RidgeView Parkway West, Waukesha, WI 53188, 800-945-5554, Fax: 262-347-2501, www.walter-tools.com.