What’s in a Name?

The bard thought not much, but “CNC Machinist” has never meant more than it does today. Once relegated to an overhead expense, Randy Pearson of Siemens Industry explains why training is now absolutely vital to your success, both in the classroom and in the shop.

Posted: January 6, 2014

I want to address everyone, from shop owners and machine builders to experienced operators and the young folks in their first months of employment, whether in the traditional chipcutting and metalforming worlds, or the newer technologies of laser, waterjet, plasma and nano welding:

You already know the value of your profession, because CNC machining and metalworking, in all its forms, impacts our lives every day. To be a “CNC machinist” means so much more nowadays, because the good ones can program, edit, simulate, run and check part quality primarily because of two factors, namely, the sophistication of the CNC and the training they’ve received, both in the classroom and on the job.

Training, by definition, is knowledge transfer and that process is happening in many ways today. And it must continue if our industry is to survive. At the very least, our industry needs to re-populate itself with an ever-changing and rapidly advancing skill set being acquired by the next generation of CNC machinists.

Everywhere I go in my work, training is at the top of the list, whether it be at a machine builder, large production department or small job shop. Especially at the latter, where the savvy shop owner knows that training people is the best hedge against the next wave of low-cost, low-quality competitors, regardless of where they’re located.

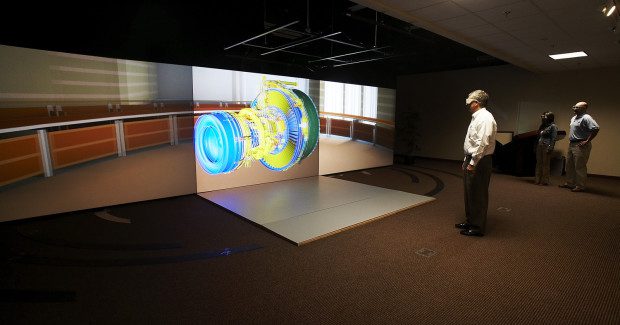

Demonstration of Siemens Nx CAD Basic Modeling Training Tutorial for Beginners: 1 | UG NX. This tutorial shows step by step how to create model in Siemens Nx.

Whether the training is done by a trade association such as the Tooling & Manufacturing Association (TMA; Park Ridge, IL), where I’m helping put together a more aggressive program, or a trade school, a builder, dealer or end user, it is essential that the training occur for operators of any CNC machine.

They can take these opportunities to learn about the CNC, but also the PLC, motors, drives, machine kinematics, programming, simulation and more. The result will be a more skilled labor force that will positively impact the competitive status of everyone in this industry, from the smallest job shop and contract manufacturer to the biggest players on the planet.

At the most basic level, high schools are “rediscovering” the track that was called “shop class” back in my day but now involves computer programming, CAD design, CAM translation and every other aspect of machining that occurs before the first part is cut.

Builders and manufacturers alike need to encourage this trend. At the recent FABTECH show, I heard a disturbing story: a room of perhaps 100 machine shop owners was asked how many would encourage their sons and daughters to enter their profession. Less than ten hands went up.

On the positive side, one major machine tool builder has just instituted a classic European-style training program where students are fully supported for two years of study, including a laptop, then given the opportunity to intern at the builder, sampling all aspects of the manufacturing process for a year while completing their studies.

They are then guaranteed a job when they finish the program and get certified. The graduates can then select the city in which they want to work. The interesting sidebar here is that the criteria for acceptance into this builder’s program are attitude and aptitude, more than hands-on experience.

For even the small shop or manufacturer, consider participating in a career day at your local high school. Young people need to know that being a CNC machinist can be a good-paying, rewarding occupation that results in making something of high quality and value. Moreover, the current work force can utilize training to get more job security by learning to run other kinds of machines, a vital skill in the flexible, busy shop world today.

Beyond this need for accelerated training to stay competitive, it will be vital for more CNC machinists to grasp the emerging technologies such as 3D. Back when I was in “shop class”, 3D meant those funny glasses you wore at the movie theater. Today, many market prognosticators are saying 3D printing will be a viable short-run manufacturing technique by the end of the decade.

Many shops I visit already use 3D for protyping and production analysis, long before the first blank goes into an expensive machining center. Technicians will be needed to program, service and maintain that machinery, plus the part designers, CAM programmers and everyone in the manufacturing chain at the company will need knowledge of it, including the CNC machinist.

In the end, making yourself more valuable as an employee will be beneficial to you, your shop and the industry overall.