Using Software To Better Run Your Shop

In today’s manufacturing environment, software has evolved. No longer designed for simple NC code and nesting parts for the best material utilization, it has become an increasingly useful and necessary tool for any production facility. Look for software modules which can be tailored to your needs and can create an ideal interaction between machine, control system, and production software.

Posted: January 22, 2014

Most manufacturers use software that enables offline programming and easy nesting. However, they are only touching the surface of what their software can do. The most recent software advances are designed to do more than program parts efficiently. Realizing what is possible is the first step in understanding the ways you can use the software to your advantage. By taking advantage of the capabilities and functions of the machine’s software you can coordinate your entire production flow, track inventory, monitor each machine and run your shop more efficiently; saving time and money. Let’s look at a few areas where your software can be used to do more around the shop.

DEVELOP 2D BLANKS FROM 3D DESIGNS

The latest developments in software allow a fabricator to produce 2D blanks for cutting and bending from 3D designs. All of the technological information needed for processing is already contained in the file. The software uses bending factors and punching tool data gathered from the punching and bending programming software. Users are then able to create the 2D blanks without requiring any 3D CAD skills. The support of numerous 3D interfaces also makes it possible to unfold different 3D designs, including those received from customers or an engineering department.

Some software can even handle imprecise models without difficulty. The ability to avoid errors from the beginning, for example, through automatic incorporation of production radii from selected tooling, leads to greater efficiency overall. In addition, processing reports provide detailed information about the end result. With the right software, it is even possible to cut open plane surfaces and define joints or cut-outs quickly and confidently using the integrated modeling function.

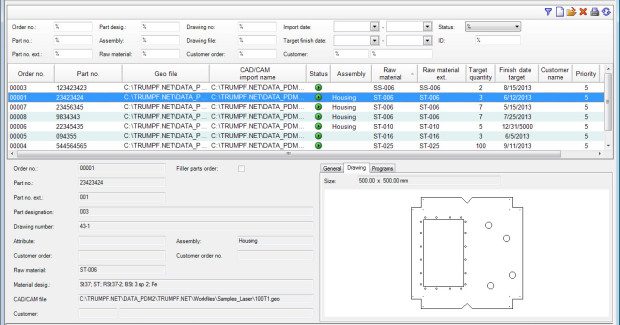

KEEP PACE WITH THE PRODUCTION PROCESS

In production-related areas it is possible to utilize software that covers many functions of conventional enterprise resource planning (ERP) systems, but which has been optimized for sheet metal fabrication. This software breaks through the classic barriers of these systems to provide continuous information flow across all levels – from company management to production. Orders need to be created only once, which improves the quality of data and saves time.

A demonstration of TruTops software.

With this software, fabricators are also always aware of the exact status of all machines and production orders. With one machine or many, reports are provided back to the ERP system to close the loop. In addition, technological advancements have also led to user-friendly tools such that enable users to receive information about production, orders and machine status anytime and anywhere.

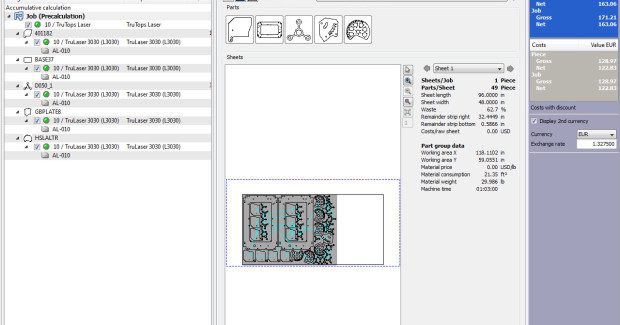

GENERATE COST ESTIMATES

For job shops, preparing quotations and facing difficult competition is simply a part of doing business. Finding the balance with a price-sensitive quotation that will also ensure profitability can be a challenge, but with certain software solutions it is simple to set up a preliminary calculation for an offer or a time calculation for production planning. The software takes machine hourly rates, consumption data and personnel costs into account and calculates rates based on the rules and technological knowledge of your programming system.

The competitiveness of the preliminary calculation is assured by such things as the integrated nesting processor. This allows the fabricator to optimize material requirements and add special considerations such as bulk discounts and foreign currencies. The software also provides for automated quotes or individual calculations to be prepared in advance by a staff member.

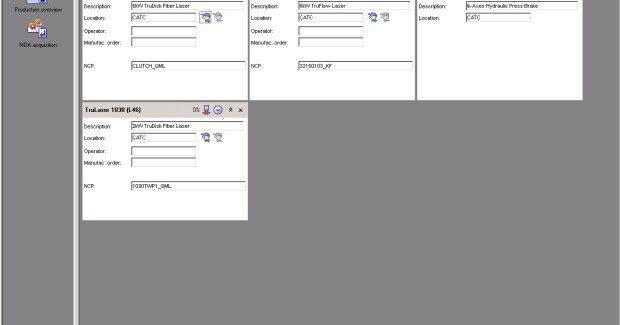

MONITOR SYSTEMS IN REAL TIME

The best software will collect and evaluate machine data in real time to enable a fabricator to react in real time. Software collects all machine data from each workplace and includes tracking of downtime, alarms, error messages and the causes of faults. Data can be stored in a central database for evaluation or use an integrated webcam to provide immediate remote diagnosis. Based on the information collected, a fabricator can easily improve upon the assignment and planning of valuable machine time.

In addition to more economical planning, software can also calculate the overall equipment effectiveness (OEE) of the machine. The interpretation and visualization of this data can be set up individually and the evaluation periods can be precisely set to the hour. The information can be exported into different target systems via PDF, HTML, RTF or e-mail, while an integrated user management system keeps unauthorized people from accessing sensitive data.

In today’s manufacturing environment, software has evolved.No longer only designed to create NC code and nesting parts for the best material utilization, it has become an increasingly useful and necessary tool for any production facility. Look for software modules which can be tailored to your needs and can create an ideal interaction between machine, control system, and production software. In addition, well defined interfaces allow for integration with your existing IT environment, allowing you to answer questions like, “What is the profit on the job?” or “Where is my part?” with a click on a button.

An integrated inventory system will also help to steer the entire material flow during production and help manage the inventory. When all machines and storage system facilities are integrated for this purpose, you will be able to see, in real-time, what’s happening in your company.