Touchless Fabrication

The improved affordability of automation and its impressive returns on investment are sweeping through the shop floors of metal fabrication as robots and advanced motion control systems replace the human hands once needed to handle and process material.

Posted: January 23, 2014

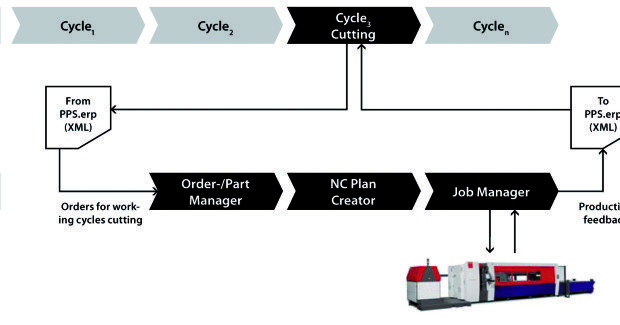

The Optiplex 4020 uses a PreView Control with a 15 in touch screen and straightforward user interface to simplify machine operation. The graphical interface clearly visualizes the cutting path and automatically determines process conditions including the required lens, nozzle, feedrate and laser output for different materials and thicknesses. The system features are complemented by a 4,000 watt Type 10 resonator with the highly efficient ECO Mode to lower operation costs.

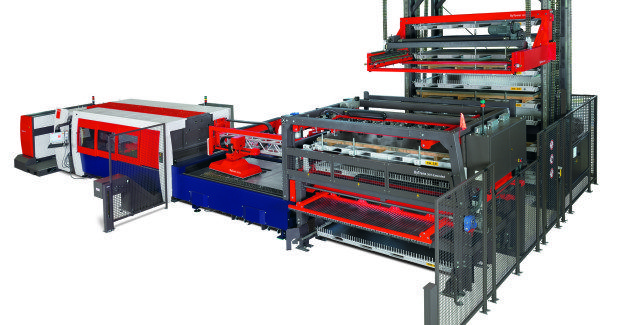

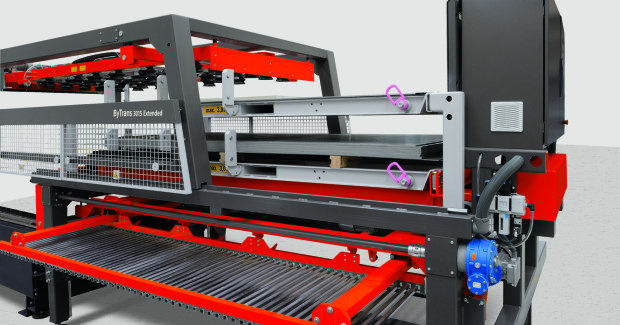

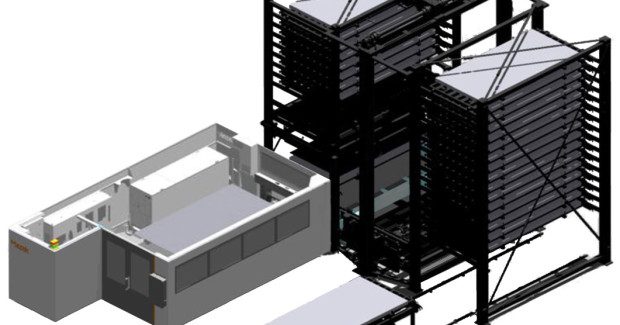

Optiplex cutting systems can be connected to Tekmag material handling systems operated with Mazak Line Controller software to minimize cutting machine downtime and significantly increase efficiency. Tekmag also carries compact vertical systems that automatically and quickly move large volumes of material while occupying minimal space.

Mazak Optonics Corporation, 2725 Galvin Court, Elgin, IL 60124, 847-252-4522, 847-252-4599, [email protected], www.mazakoptonics.com.

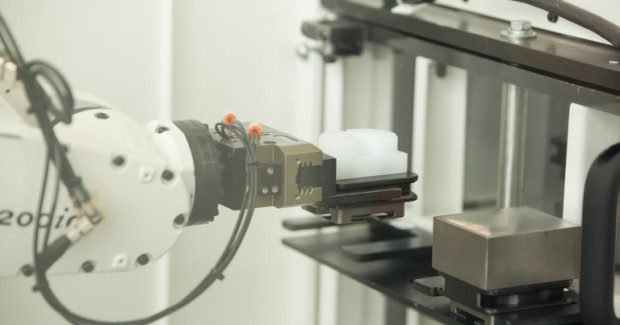

In machining operations, the VCN Compact Automation Cell from Mazak Corporation (Florence, KY) is a self-contained, prefabricated work cell that provides efficient, cost effective lights-out manufacturing for small-to-medium sized parts. The cell incorporates a Vertical Center Nexus Compact 5X 5-axis vertical machining center with a standalone Fanuc LRMate 6-axis robot with two-jaw parallel gripper and a System 3R palletizer system to process as many as 72 individual part sizes measuring up to 3.9 in wide x 3.9 in deep x 3.9 in tall and weighing as much as 8.8 lb.

The high torque 12,000 rpm, 25 hp, CAT 40 spindle aggressively machines tough materials such as stainless steel, Inconel and titanium. An optional 40 hp, 20,000 rpm spindle or 42,000 rpm HSK E40 ultrahigh-speed spindle are also available. Reduced part cycle times result from the machine’s three linear axes that attain high speed rapid traverse rates of 1,417 ipm and fast feedrates of 315 ipm. This VMC accommodates 20 tools in its tool magazine (30 tools optional) to further increase part production versatility (see Figure 9).

For rigid and precise 5-axis machining, a rotary/tilt table on the VMC is constructed with durable high-speed, backlash-free roller cam drive technology that rotates and tilts the table at speeds of 100 rpm and 75 rpm, respectively. The table, which measures 3.94 in (100 mm) OD and 1.57 in (40 mm) ID, tilts at angles from -20 deg to 120 deg with a holding torque of 249 ft-lb and machining torque of 63 ft-lb.

An MX Hybrid Roller Guide System dampens vibration to extend tool life, handle higher load capacities, accelerate and decelerate faster to shorten cycle times, eliminate tramp oil in the coolant by utilizing a greener grease-based lubrication system, and last longer with less required maintenance. An advanced MATRIX 2 CNC control optimizes 5-axis machining for higher processing speeds in small increment operations, 5-axis spline interpolation for smooth toolpaths from long block-by-block programs, easy tool vector control and shorter cycle times as well as superior surface finishes.

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41022-0970, 859-342-1647, [email protected], www.mazakusa.com.

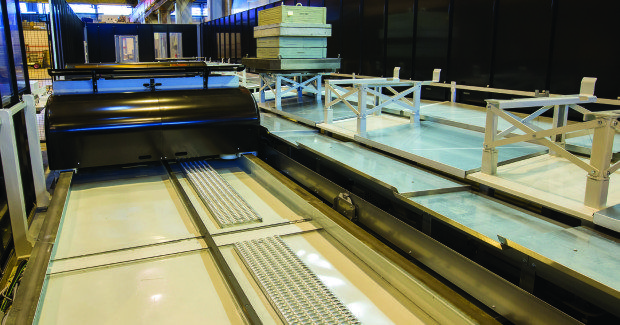

For shops handling heavy pallet loads up to 7,500 kg, Fastems, LLC (West Chester, OH) offers their FPC-7500 Flexible Pallet Container type automation system, a progressive alternative to outdated “pallet pool” technology that provides shops and machine tool builders with a complete FMS installed in a “container.”

This single-level flexible manufacturing system handles 1,000 mm and 1,250 mm pallets that require large load capacity and replaces the typical crane-style pallet changer with a dual-rail guided pallet change vehicle sporting a unique low-profile design that accommodates heights up to 2,300 mm and diameters up to 2,300 mm (see Figure 10).

This FMS comes equipped with the latest Manufacturing Management System (MMS5) Cell Controller software that can extend from a single manufacturing cell to a full featured shop-wide system integrated with other manufacturing plant software such as ERP and MRP systems, and is fully compatible with MT Connect. Shops can install the FPC-7500 with a new machine investment or add it to an existing machining center upgrade.

Fastems, LLC, 9850 Windisch Road, West Chester, OH 45069, 513-779-4614, [email protected], www.fastems.com.

MACHINE TENDING

High production business and job shops with smaller lot sizes are both integrating their new or existing equipment with robots that improve productivity by reducing load/unload times and making more parts in less time through improved machine utilization.

For example, LoadWorld® is a pre-engineered standard robot system for machine tending from the Motoman Robotics Division of Yaskawa America, Inc. (Dayton, OH) that uses robots such as the unique 7-axis SIA20D with payloads from 20 kg to 200 kg to produce parts during breaks or off-shift periods.

LoadWorldincludes a four-drawer fabricated steel part stocker so the operator can load and unload parts from one drawer while the robot continues to work on another. All of the drawers can run the same part or each drawer can be configured for a different part. The drawers can be outfitted with tooling or a powerful MotoSight™ 2D vision system that uses a Cognex In-Sight® Micro camera and Yaskawa Motoman Pendant Vision application software to easily add vision to the robot so it can locate parts, identify them and perform quality control functions to reduce tooling costs (see Figure 11).

http://youtu.be/1yO_d_g6vTg

A demonstration of LoadWorld robotic machine tending with Robotiq Adaptive Grippers. The electric grippers can accommodate for a wide range of part sizes an geometry that can be found on the drawers.

LoadWorld uses an innovative, extremely flexible 2-Finger Adaptive Gripper from Robotiq (Quebec City, Canada) to handle a variety of parts in a high-mix, low-volume machine shop with two articulated fingers that can adapt automatically to parts of varying size and shape. This eliminates the need for a tool changer and multiple tools. Compared to custom tooling, the Adaptive Gripper reduces setup costs and cycle time with its short stroke and elimination of tool change delays.

The fully programmable robotic gripper provides parallel, encompassing and inside gripping modes to handle flat, square, cylindrical and irregular part geometries. Its precise force and speed controls handle parts with different rigidities from brittle to stiff. Accurate finger control partially opens/closes for enables fast cycle times.

Yaskawa America, Inc. Motoman Robotics, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, [email protected], www.motoman.com.

Robotiq, 966 chemin Olivier, Suite 325, St. Nicolas, QC G7A 2N1, Canada, 418-380-2788, Fax: 418-800-0046, www.robotiq.com.

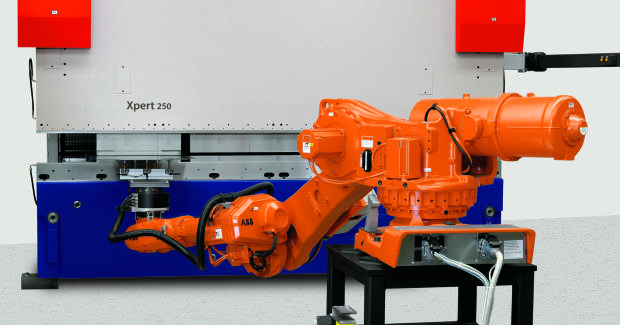

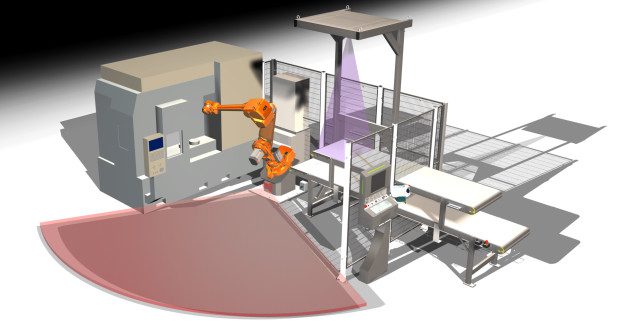

ABB Robotics (Auburn Hills, MI) is collaborating with SVIA Industrial Automation of Sweden to bring the SVIA PickVision™ Smart Camera vision system to their industrial robots in North American. SVIA equips the robots with highly flexible, easy to use vision for tending CNC lathes, vertical and horizontal machining centers and grinders (see Figure 12).

A demonstration of the SVIA PickVision 3D with an ABB robot that can be used for machine tending.

PickCision is tightly integrated with ABB’s powerful IRC 5 Controller for “plug and play” simplicity that is easily set up and adapted to the shop’s specific applications. It can be programmed on a PC or tablet and features a Window 8 touch screen interface. The system includes remote service capabilities, including a specially designed iPhone App.

ABB Robotics, Inc., 1250 Brown Road, Auburn Hills, MI 48326, 248-391-9000, [email protected], www.abb.com/robotics.