The Maintenance Platform of the Future

For shops that have operated the same way for 50 years and don’t really know where to start a predictive maintenance program or where to focus PDM for competitive advantages in the future, Tom Hoenig of GTI Spindle Technology shares some critical insights into starting up and sustaining an effective system using the latest technology and devices.

Posted: January 6, 2014

Implementing a predictive maintenance (PDM) program can be tough in today’s manufacturing environment. Despite the proven success of many programs, many shops have operated the same way for over 50 years and don’t really know where to start a PDM system or how to use its benefits for a competitive advantage.

Things are rapidly changing. As we enter into another dimension of communications – the world of sharing cloud data and portable device computing – we can now send real-time data to many other personnel to view. This capability offers a shop many advantages, especially when they apply it to predictive maintenance.

For example, a maintenance technician is collecting data from machinery and finds something drastically wrong that needs immediate attention. With today’s technology he has more options at his fingertips than ever before. If he is collecting data from an Internet-connected device, he can send the information to the cloud with an alert attached so that people monitoring will get the alarm, or he may also be able to email or text this data immediately to a decision-maker for quick action.

In the past, no matter how the technician was collecting the data, he would have to wait until he was done with his route, return back to a computer, then upload the data to send to others or do further analysis himself. Many times in this scenario an emergency would be forgotten because other urgent firefighting tasks took precedence. Unless the technician actually left his post and stopped what he was doing to alert a subordinate or decision maker, action was rarely taken.

http://youtu.be/t29vKhamrCQ

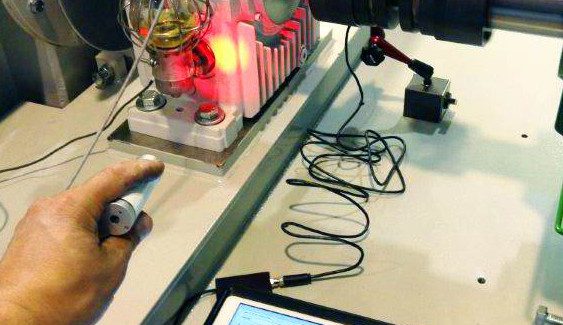

Demonstration of the VibePro 6 iPad vibration analyzer and dynamic balancer for frequency analysis, FFT and Waveform Plots and more. It has a bearing fault frequency calculator and markers on the spectrum for bearing frequencies, RPM, high peak and harmonics. The system generates complete reports on RMS, peak values, machine pictures, severity plots, custom drawings and notes by user, or email reports and data. The system can be synchronized to the VibeTrend app to remotely monitor the overall value of the vibration for each machine.

A tablet, such as an Apple iPad, is a powerful tool for collecting data and getting work done. Many shops have already adopted tablets for filling out purchase orders and other business forms and doing many other daily tasks where employees collect data. Because most people already understand how to use the operating system, there is little to no learning curve required to work with tablets and smart phones.

As tablets gain popularity, shops are adopting ways to use their simplicity, portability and connectivity to everyday business tasks, from collecting credit card information to bar code scans, photos, custom reports for field engineers, and even navigation recorders for pilots. Now imagine what can be done in maintenance by adding sensors and other complex tools to tablet devices:

VIBRATION ANALYSIS

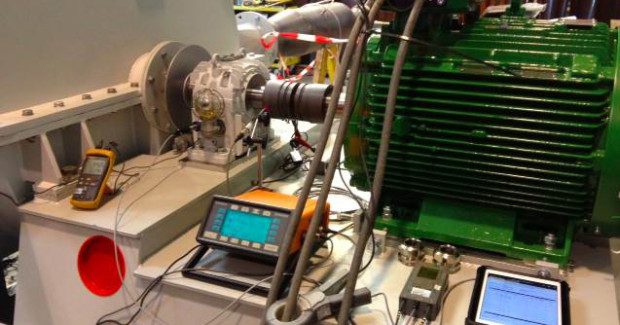

Vibration analysis, one of the leading measurements taken in the predictive maintenance community for equipment reliability, can detect unbalance, misalignment, bent shafts, eccentric rotors, sheaves, resonance, mechanical looseness, oil whirl, bearing failures, gear mesh, motor problems and other conditions.

http://youtu.be/xocaKSg5mjU

A demonstration of the VibePro app on the iPhone 4S to take readings, record data, send reports via email or using dropbox.

Most modern analyzers have the balancing capability to correct vibration on the spot. More importantly, data collectors are designed to trend data over time to predict exactly when failures will occur.

INFRARED THERMOGRAPHY

Infrared thermography measures temperature to determine machine operating conditions and detect thermal anomalies and areas that are hotter or colder than they should be. Infrared practices detect problems in electrical switch gear,

gear boxes, electrical substations, transmissions, circuit breaker panels, motors, bearings, steam lines, and other components. This technology also helps project when important assets are going to fail.

MOTOR CONDITION ANALYSIS

Circuit analysis and power readings of the motor windings and motor rotor provide important information about the running condition and general health of the motor.

PRECISION BALANCING

Precision balancing is another vital instrument used to solve equipment vibration and premature failure. This can be performed on machines made for balancing or conducted in the field using very expensive equipment that is typically difficult to use and requires many hours of training.

PRECSION LASER ALIGNMENT AND LEVELING

Yet another tool to level and precision align equipment that would typically involve hours of training and expense.

THE FUTURE

In planning for a more competitive future, shops must recognize the differences between using a dedicated electronic

measuring device they already have vs. investing in a tablet computer or smartphone for analysis. There are several reasons:

- All of the competitive features of a tablet cannot be found on a dedicated measuring device, such as email, photos, notes, phone calls, texts, video conferencing, Internet searches for information, storage and viewing of important asset manuals and blueprints, maps, and much more.

- Ease of use of a common operating system.

- Multiple sensors and applications on one platform/device.

- Portability and durability with the available cases.

- Wireless connection to servers, cloud, and Internet with the ability to send out data wirelessly.

- Continually updated software for free.

Tablet devices are clearly marked to be a maintenance platform of the future. Not only for all of these sound reasons that are mentioned, but also due to the fact all of our youth are using and learning on them in our educational systems.

Shops should begin to research suppliers with the ability to add vibration analysis, precision balancing, precision

shaft alignment and leveling, and other external tools and sensors to these devices. They should calculate their return on investment on a PDM program that uses these maintenance technologies to start their program today – with a focus on tomorrow.