How To Automate Deburring & Finishing: Nampower Abrasive Disc Brushes

These new abrasive disc brushes contain a unique combination of ceramic and silicon carbide filament that produce maximum burr removal rates while providing an ideal surface finish at the same time.

Posted: January 31, 2014

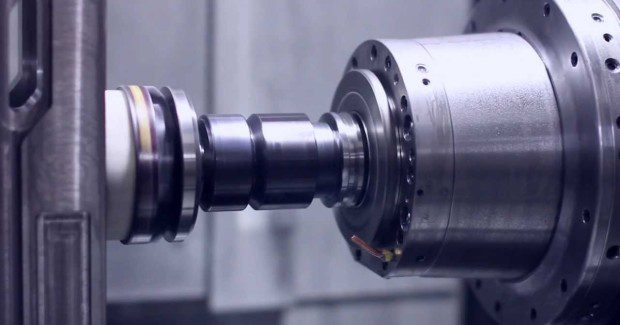

Brush Research Manufacturing (Los Angeles, CA) is excited to announce a full range of truly unique finishing and deburring tools. Our new abrasive disc brushes contain a unique combination of ceramic and silicon carbide filament that produce maximum burr removal rates while providing an ideal surface finish at the same time. The discs are manufactured using a fiber reinforced thermoplastic base that results in less vibration and greater process repeatability.

Our professional grade tool holder provides the added advantage of lubrication from the inside of the brush that greatly improves tool life and cutting action. The brushes are available in 2 different styles: Dot Style for general purpose deburring and surface finish applications and the Turbine Style brush for medium and heavy deburring applications. The brushes are available in two different trim lengths for the right combination of flexibility and aggressiveness and 3 different diameters to cover a broad range of finishing applications.

These high-performance tools create reliable, consistent and cost effective results. Nampower™ Disc Brushes are easily integrated into today’s automated machinery, CNC machining centers, transfer lines and robotic cells.