CAD/CAM Machining Software: The Latest Trends and Advances

Nothing is changing faster or more profoundly than the software used to design and machine parts. To help shops keep up with the latest competitive advances being introduced on the shop floor, here is a report on some of the newest CAD/CAM software.

Posted: January 24, 2014

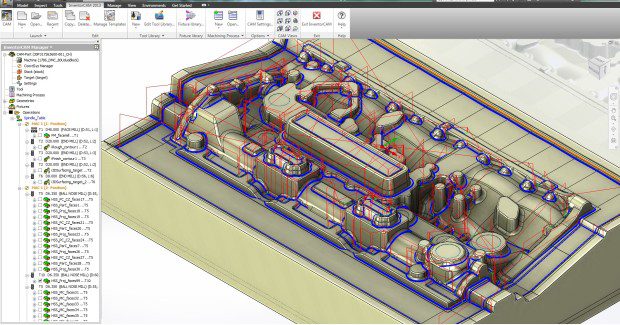

Parts of Edgecam have gone mobile in 2014 R1: The new Live Job Reports is simple, easy and quick for small shops, while being very powerful for advanced shops that want to customize it. It keeps the same performance on both small and large databases, easily handling thousands of tools and toolkits. As this function runs on a website, the client can be a PC and even a tablet or phone, making it possible to access the reports from the shopfloor on the go, without the need to print.

A new Finding and Editing Fillets on Imported Models function in Part Modeler finds fillet radii on third-party imported solid models and allows them to be edited to help prepare CAD data for manufacture. Other Part Modeler enhancements include advanced loft and sweep commands which allow shops to loft dissimilar shapes and add guide curves.

Vero Software Limited, Hadley House, Bayshill Road, Cheltenham, Gloucestershire GL50 3AW, UK, +44 (0) 1189 756084, [email protected], www.vero-software.com.

POWERFUL GENERAL PURPOSE MACHINING

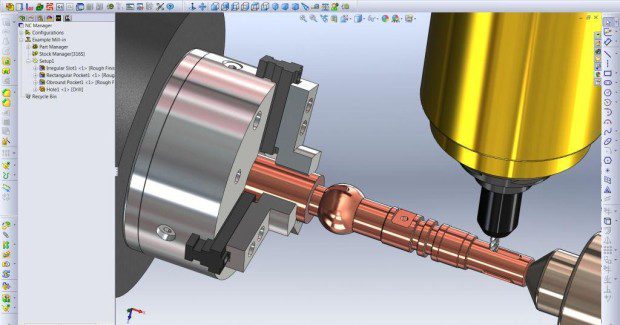

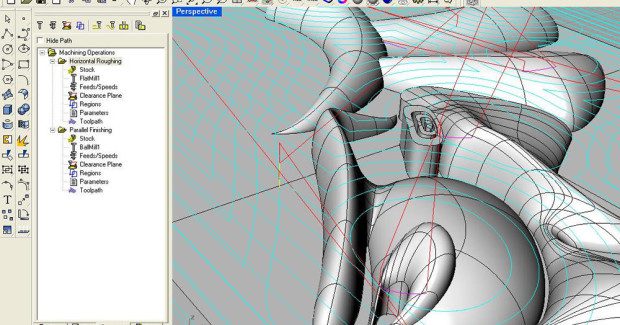

MecSoft Corporation (Irving, CA) offers RhinoCAM 2014, a plug-in that combines the free-form modeling power of Rhino with the legendary machining capabilities of VisualMILL in an easy to use yet powerful general purpose machining program for the general machinist. The plug-in includes four CAM modules, each of which run integrated inside the Rhino 5 CAD program and can be bought and licensed independent of each other. All of the CAM modules are significantly improved to provide shops with a powerful and complete manufacturing platform.

A webinar that walks through the new features of RhinoCAM 2014.

The RhinoCAM-MILL module features enhanced multi-threading toolpath generation with 2-axis and 3-axis improvements in High Speed Pocketing, Pocket Spiral Machining, high speed cleanup loops, Triangular Tabs/Bridges in Profiling, Pocket Spiral Machining in Horizontal Roughing and other process areas that include better memory management for 4-axis R modules and better 5-axis angle limits processing (see Figure 10).

The new TURN module uses upgraded 3D model slicing tools and an updated Feeds/Speeds table and calculator. It introduces a Toolpath Viewer with Diameter mode programming and additional thread programming variables. The RhinoCAM-ART module features Texture Mapping to Relief models, an Improved Relief Curves Selection Display for Relief Operations, an Extrude Puff Operation, a Noise Filter for Vector Operation, and Shape Library Implementation. Free demo software of RhinoCAM 2014 can be downloaded at http://rhinocam.com.

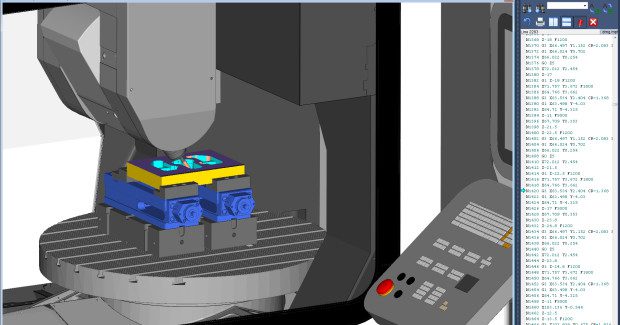

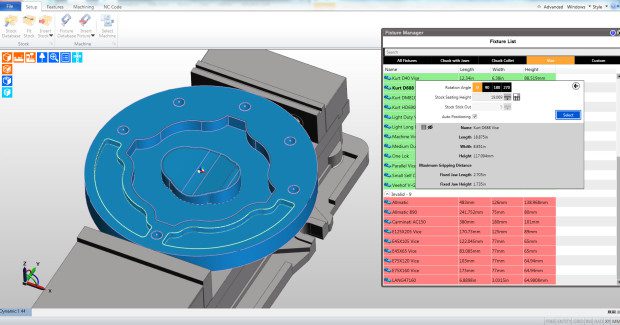

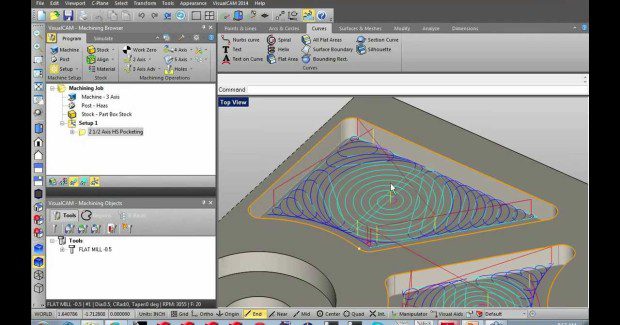

MecSoft also released their VisualCAD/CAM 2014 standalone CAD/CAM software suite that includes the modules VisualMILL, VisualTURN, VisualNEST, and VisualART, each of which run integrated inside the VisualCAD 2014 base CAD platform and can be bought and licensed independently of each other (see Figure 11).

A webinar that walks through the new features of VisualCAD/CAM 2014.

VisualCAD continues to be provided as a completely free design tool. Free demo software of VisualCAD/CAM 2014 can be downloaded by clicking here.

MecSoft Corporation, 18019 Sky Park Circle, Suite K,L, Irvine, CA 92614-6386, 949-654-8163, Fax: (949) 654-8164, [email protected], mecsoft.com.

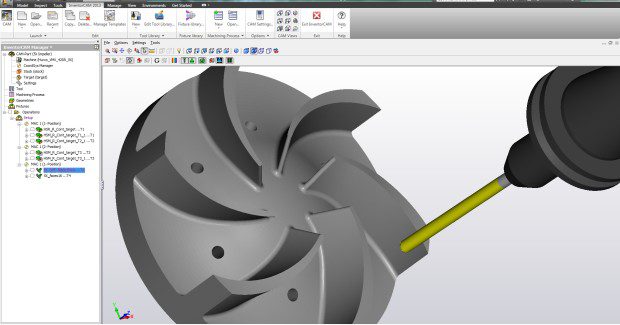

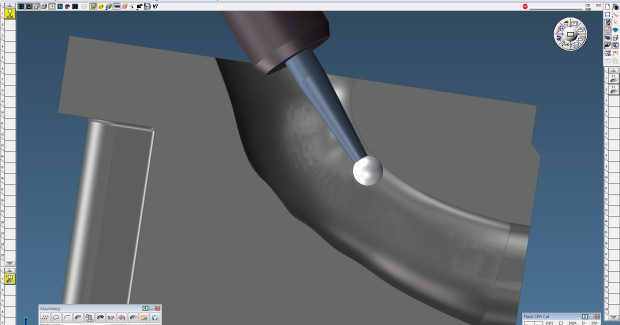

5-AXIS PORTING SIMPLIFIES MACHINING OF ENGINE PORTS AND SIMILAR GEOMETRY

Gibbs and Associates (Moorpark, CA) offers its new 5-Axis Porting option for GibbsCAM that provides a specialized interface optimized for the machining processes and cutting tool motion required to machine tubular openings that change shape and curvature from one end to the other. The Porting option complements GibbsCAM 5-Axis by enabling easier and faster programming of port-like openings through a condensed interface that provides toolpath options and machining strategies optimized for machining such open shapes (see Figure 12).

http://youtu.be/qQoJ_i7iiew

An overview of the features in 5-Axis Porting Option.

The software can automatically detect the spine curve through the port and properly align the toolpath. Using available tool reach, the software can split upper and lower operations automatically by maximum tool reach, midpoint or user selected percent of reach, ensuring proper toolpath blending between upper and lower sections. Machining strategies include roughing, rest roughing, and spiral and plunge (along) finishing. To maintain tool rigidity, 5-Axis Porting maintains 3-axis machining (3 + 2 mode) as far into the port as possible until 5-axis simultaneous motion is required.

Tool tilting is automatically calculated for optimal angles, without the need to split surfaces or create tool axis control splines, producing smooth, gouge free 5-axis motion. Users may choose to machine only the top of a port, only the bottom, or both sides, in a single operation. In addition to ease and speed, the GibbsCAM 5-Axis Porting option generates a cleaner, more efficient toolpath for faster machining and higher quality parts.

Gibbs and Associates, 323 Science Drive, Moorpark, CA 93021, 805-523-0004, Fax: 805-523-0006, www.gibbscam.com.