Laser Cladding Offers Unique Advantages

Here is a brief overview of high power diode laser cladding that can offer improved process throughput, superior overall clad quality, very low dilution levels, reduced heat input, minimal part distortion and better clad deposition control than most traditional technologies.

Posted: December 17, 2013

Cladding is a widely used process for improving the surface and near surface properties (e.g. wear, corrosion or heat resistance) of a part or to re-surface a component that has become worn through use. Cladding involves the creation of a new surface layer on top of a base material. This is distinct from surface hardening, which simply entails changing the properties of the substrate itself in a thin surface layer.

There are currently quite a number of different techniques for performing cladding, each with its own specific characteristics in terms of the materials employed, the quality of the clad layer and various practical issues including throughput speed, process compatibility, and cost.

This article provides a brief overview of high power diode laser cladding which can offer improved process throughput, superior overall clad quality, very low dilution levels, reduced heat input, minimal part distortion and better clad deposition control than most traditional technologies.

TRADITIONAL CLADDING PROCESSES

Most traditional cladding technologies can be broadly classified as either arc welding or thermal spraying methods. Each of these approaches has its own advantages and limitations and, as a result, there are certain types of applications for which each is best suited.

http://youtu.be/58i1Rcwsw30

This demonstration of Coherent’s highly efficient HighLight D-Series features the HighLight 8000D, a high power direct-diode laser system with 8 kW of power at 975 nm. The HighLight 8000D is shown performing large area laser cladding of Stellite 6 (a high quality laser cladding powder from Hoganas) on flat and round low carbon steel materials.

There are a number of different arc welding techniques such as gas tungsten arc welding (GTAW), plasma transferred arc (PTA), gas metal arc welding (GMAW), submerged arc welding (SAW) and several others. In all these processes, an arc is established to melt the surface of the base material, usually in the presence of a shield gas. The clad material is then introduced in either wire or powder form and is also melted by the arc, thereby forming the clad layer. The various embodiments of this basic approach differ in the details such as using the filler metal as the electrode, the use of flux, or the ability to use a hot (pre-heated) or cold filler wire.

In the most general terms, all arc welding techniques deliver a fully welded, metallurgical bond having high strength, good impact properties and low porosity. Arc welding methods also offer high deposition rates (which translates into high throughput) and relatively low capital cost for the equipment.

The major negatives of arc welding cladding are high heat input into the part and, depending upon the particulars, relatively high dilution of the clad material (that is, unwanted migration of the base material into the clad layer). Heat input into the part can cause mechanical distortion often creates the need for further post-processing after cladding.

In addition, it is not always possible to realize in practice the high deposition rates of which arc welding processes are theoretically capable. This is because dilution, heat input, distortion, hardness and other metallurgical properties are sometimes negatively affected when the arc energy is increased beyond an optimum level that is generally at the lower end of the deposition rate range.

In thermal spraying, the clad material, most typically in powder form, is melted by a flame or electricity and then sprayed on to the work-piece. In most cases, this is a low-heat process, where the substrate remains typically < 200 deg C. The four most common embodiments of this approach are flame spraying, arc spraying (where wire is used as a consumable), plasma spraying and high-velocity oxyfuel (HVOF).

The primary advantage of all thermal spraying techniques is the low heat input into the part which means there is no heat-affected zone and minimal dilution. It also enables the process to be utilized with a wide variety of substrate materials including metals, carbides, ceramics and even plastics. Thermal spraying also supports a very broad process window in terms of the range of coating thicknesses that can be achieved and the deposition rates supported, although these coating tend to be thinner than arc welded coatings.

One of the significant drawbacks of thermal spray processes is that the bond between the clad layer and the substrate material is mechanical, not metallurgical, in nature. This can lead to problems with adhesion and poor wear resistance, especially with pinpoint loading.

Also, thermal spray claddings often exhibit some level of porosity and bonding defects. The presence of such defects in the coating is of concern because these can provide a path for a corrosive solution to reach the base materials. Reduced corrosion resistance has been reported and appears to be related to preferential attack along the inter-particle boundaries.

LASER CLADDING BASICS

Laser-based cladding techniques provide several quality and process related advantages over both arc welding and thermal spray methods. However in practice, traditional laser types have not always delivered on this promise and have also displayed significant drawbacks in terms of output characteristics, operating costs and ease of implementation. In response to the need for a more optimal source for applications such as cladding, welding and heat treating, laser manufacturers have developed the high power direct diode laser.

A high power direct diode laser is a compact assembly consisting of a very large number of lower power (about 100 W each) semiconductor laser emitters, whose output is combined into a single beam. Typically, this beam takes the form of a long, thin rectangle, usually around 3 mm wide, and anywhere from 6 mm to 36 mm long.

High power diode lasers systems with output powers of up to 10 kW are currently available. Because of their all solid-state construction, diode lasers systems generally offer greater electrical efficiency (~ 45 percent), smaller size and higher reliability than other laser types.

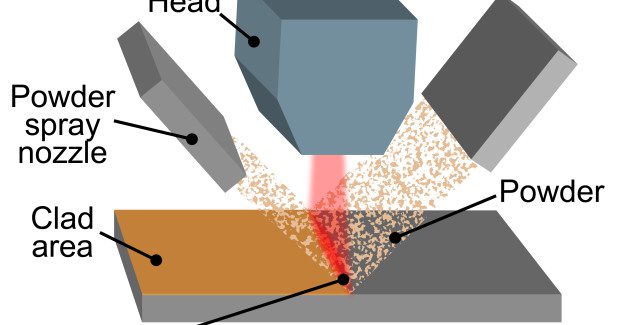

The line beam output from the high power diode laser is well suited to most metalworking applications, since it can be swept across the part to enable rapid processing of large areas. For example, in the case of powder-based cladding, the long axis of the line beam is oriented perpendicular to the direction of beam travel, as shown in the drawing. With a beam length of 24 mm, for example, a single pass “effective” clad width of 20 mm can typically be achieved. See Figure 1.

HIGH POWER DIODE LASER CLADDING ADVANTAGES

In some ways, high power diode laser cladding combines the best features of both arc welding and thermal spray methods. When compared to arc welding methods, diode laser systems offer lower heat related distortion, reduced dilution, extremely low porosity and better surface uniformity. Together, these properties substantially reduce the need for post-processing and its associated time and cost.

The high quench rate of the diode laser process also produces a finer grain structure in the clad leading to better corrosion resistance. Moreover, these benefits are generally not significantly negatively affected as laser power and deposition rate increase. In contrast, for most arc welding processes, clad quality suffers with increasing power and deposition rate. Finally, the line beam shape can process large areas rapidly with a high degree of control over clad width, thickness and deposition rate.

Both the diode laser and thermal spray techniques avoid significant heat input into the part and minimize dilution. This low level of dilution (~ 4 percent to 7 percent) typically supports the attainment of the desired surface chemistry for the clad deposit in a single cladding pass, thereby minimizing process cost. Unlike thermal spray, diode laser cladding forms a true metallurgical bond with the base material. The result is better adhesion and wear resistance.

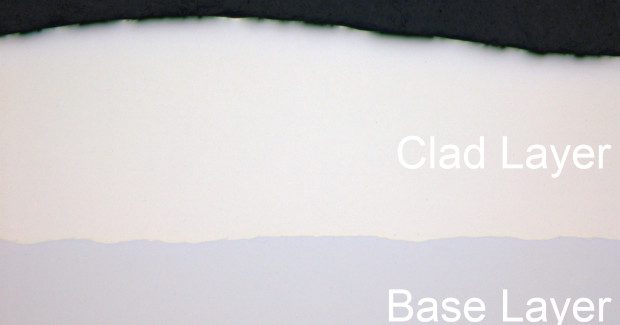

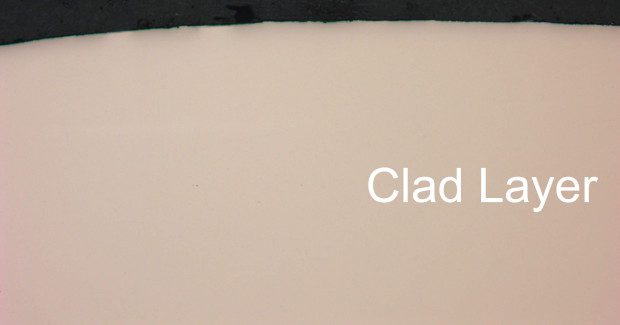

Furthermore, metallurgically bonded clads produced with the diode laser limit the cracking and de-lamination sometimes associated with mechanically bonded coatings. The microstructure photographs demonstrate some of the most desirable features of laser cladding. See Figures 2, 3, 4.

The diode laser cladding process is also compatible, and frequently used, with standard alloy materials commonly available in powder form (see table). These include a wide variety of standard stainless steels, tool steels and corrosion- and heat-resistant nickel alloys. Most importantly, because of the low dilution and other attributes obtained with laser processing, the clad material exhibits a chemical composition having the characteristics of the original bulk material.

This is important, because it means the clad layer will behave predictably, with the same desirable and expected properties of a bulk sample of the same alloy.

Table 1. Commonly Used Laser Cladding Materials

| Material | Type | Alloy |

| Stainless steel | Austenitic | 304, 316, 309, 310 & 904 |

| Martensitic | 410, 420 & 431 | |

| Nickel alloys | 625*, C-276*, C-22* & 718* | |

| Tool steels | High Speed Steels | H13 & M2 |

*Is registered trade mark of Special Metals Corporation

In contrast, this is not generally true when using powder with welding and flame spray deposition techniques. Clad properties can deviate from those of the original powder because of dilution and porosity in the clad layer.

Furthermore, flame spraying tends to rely on less common alloy systems that have been developed specifically for these application methods. Examples are be self-fluxing nickel alloys and special carbide bearing cobalt base alloys. Since these alloys are not common in bulk form (wire, rod, sheet, and plates), their properties are less well-known to those who select materials.

The fact that the material properties for laser clad layers are more familiar to users will eventually favor the use of this technology in an increasing number of industrial applications.

The lower dilution of laser cladding as compared to arc welding methods also allows the desired results to be achieved with fewer clad layers. For example, when TIG or MIG welding IN-625 (a trademark of Special Metals Corporation), the desired iron content in the clad layer might be specified to < 5 percent, or, in certain cases, to < 10 percent. Due to the high dilution experienced with these welding techniques, a large number of cladding layers must typically be deposited before this low dilution level can be reached.

In contrast, dilution levels below even 5 percent can be achieved in a single layer with laser cladding (even lower dilution can be reached, but this might involve inadequate melting of the bulk material and therefore may not create a true metallurgical bond). The benefit of this is reduced cost. Specifically, a single layer clad takes less time to produce than a multilayer clad, and also uses less cladding material.

The limitations of high power diode laser cladding are mainly practical in nature. Specifically, the initial capital cost is higher than other cladding techniques and the physical size of the equipment can make it difficult to integrate into some production settings. Additionally, in some cases, laser cladding doesn’t support the deposition rates achievable with arc welding (albeit usually with a sacrifice in clad quality for fast arc welding). The table compares the key parameters of laser diode and arc welding cladding processes.

Table 2. Key Parameters of Laser and Arc Welding Cladding Processes at High Depositions Rates.

|

Cladding Process |

Power (kW) |

Deposition Rate (lb/hr) |

Efficiency (lb/kW/hr) |

Relative Heat Input/ Distortion |

Notes |

|

High Power Diode Laser |

7 |

20 |

2.9 |

1 |

Powder Cladding Rate, Expect Greater Efficiency & Higher Deposition With “Dual Hot Wire” |

|

Plasma Arc Welding (PTA) |

7.5 |

12 |

1.6 |

3 |

250 amps x 30 volts, + “Hot Wire” Power 50 kJ/in |

|

Gas Tungsten Arc Welding (GTAW) |

6 |

10 |

1.7 |

6 |

400 amps x 15 volts, + “Hot Wire” Power |

|

Gas Metal Arc Welding (GMAW) |

12 |

17 |

1.4 |

10 |

400 amps x 30 volts7/64” Wire 43 kJ/in 38kJ/in |

|

Submerged Arc Welding (SAW) |

25 |

30 |

1.2 |

20 |

800 amps x 32 volts, 5/32” Wire, DC 56kJin |

In conclusion, the particular optical and operating characteristics of high power diode lasers now make them an excellent match for cladding applications. Specifically, they can produce clads of high quality and with a wide range of materials which already have good market availability and documented service performance.

In particular, laser processing meets the increasing need in the market for cladding with standardized alloys. The superior integrity of the laser clad coating with standard alloys delivers results that, to a higher degree, conform to the principle alloy, resulting in more predictable performance. In addition, laser cladding can be accomplished at relatively high deposition rates and usually only requires a single layer, making it a fast process.

These factors, together with low heat distortion which substantially reduces the need for post processing, makes high power diode laser cladding cost competitive with traditional arc welding and thermal spray methods.