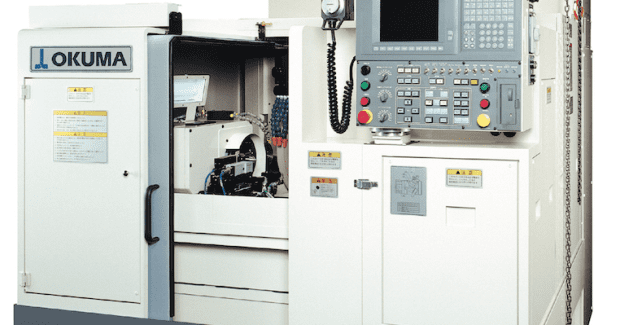

CNC Grinder Supports High-Volume, Automated Production Environments

This CNC grinder from Okuma America that is designed to support outside diameter finishing of small-to-medium-sized parts.

Posted: December 16, 2013

Okuma’s (Charlotte, NC) powerful, compact, GA-26T CNC grinder with automation by Gosinger is designed to support outside diameter finishing of small-to-medium-sized parts in high-volume automated production environments. To make the most of floor space, the T-Series is engineered to hold the workpiece stationary while the grinding wheel traverses back and forth.

The GA/GP-T Series is designed to support O.D. finishing in high volume, automated production environments. To make the most of floor space, the T-Series is engineered to hold the workpiece stationary while the grinding wheel traverses back and forth.

This compact design, available in both angle and plain head, is extremely cost effective for production lines with part sizes up to 25.59 in long and up to 110 lbs. A variety of wheel sizes, combined with interchangeable parts between the F-Series and the T-Series machines creates a flexible grinder. This GA-26T features in-process gauging and wheel balancer provided by Marposs as well as a 20 HP wheel spindle.