Robotic Welding Automation for the Small Job Shop

The conclusion of our three-part series on automation for the small shop examines the primary components involved in the justification and payback of your capital expenditure so that you can optimize your financial return on investment.

Posted: November 7, 2013

The approach to and perception of achieving an effective Return on Investment (ROI) on a capital expenditure is as diverse and as broad as the title above suggests. It requires time and wide ranging vision, and, in reality, is no less important than establishing the correct payload and reach of a robot, with equally disastrous circumstances if you get it wrong.

It is not uncommon for the purchase of robotic automation to be undertaken without an ROI evaluation, often resulting in the perception that the project did not go well. The usual outcome of this activity is the syndrome of “we’ve tried that in the past and it failed.” Historical fears and mistrust from the botched implementation take over, relegating a company to stagnation as future opportunities to improve are routinely avoided.

In most cases, if an accurate ROI analysis is crafted during the due diligence process, it will clearly show the potential benefits and risks of the project and the outcome of implementation will be clearly understood from the start.

The first area for consideration is identifying the criteria that will have a positive fiscal impact. The second is to understand the magnitude of savings associated with the items selected for evaluation.

When operating and maintaining a robotic arc welding cell you need to ensure you achieve maximum uptime to deliver your return on investment. The ArcWelding PowerPac software add-in to RobotStudio is easy to use and allows arc welding cells to be programmed off-line using a PC. All steps of the arc welding process can be tested and validated without taking the robot cell out of production. This ensures shorter project lead times and better performance of your robots.

The obvious ROI considerations include labor savings and increased throughput, but a host of other items often get overlooked because they are too hard to quantify, many of which may have an even greater impact on the bottom line. Things like increased quality, greater customer satisfaction, reduced waste, improved lead times and better inventory control may take more effort to determine, but these are often the areas where the greatest benefits of robotic automation are ultimately realized.

The duration or purview of the ROI analysis is one further area that is often overlooked or under considered. The most accurate review should cover a realistic lifetime of the equipment, not just the first year or two. Though the ROI of a robotic welding investment is typically realized in months rather than years, the analysis should not stop there.

When properly assessed over the full life cycle of the equipment, the complete magnitude of the project benefits, both qualitative and quantitative, will help facilitate a more confident and enthusiastic decision (see Assessment of ROI diagram). Let’s take a closer look at some of the primary components of a thorough ROI evaluation:

LABOR

As noted earlier, one of most obvious attributes for consideration in the ROI is the labor content. People with the skills, capabilities and associated overheads will have a significant influence over the outcome of the ROI. Obvious aspects are wages, shift patterns and benefits. Not so obvious are repetitive strain injury costs, health and safety costs associated with people, and the potential redeployment of skilled labor to more rewarding jobs and its positive impact.

There is a wide range of labor consequences to be considered, but the redeployment of the skilled labor to positions of greater authority and higher satisfaction is one of the most overlooked aspects of an ROI. If the implementation of a welding or cutting robot cell releases between three and four people to other duties, there is often a secondary benefit to be realized.

Knowing your manufacturing requirements and the skill sets of your staff will provide you options that make the greatest impact on the ROI. Redistributing skilled people to understaffed areas of manufacturing, or to areas where quality has room for improvement, allows you to reapply those resources to your further advantage.

HARDWARE AND SOFTWARE

“Uptime” is a small word with large implications to a solid ROI. The robotic hardware and software that you select are critically important to keeping your system up and running throughout the manufacturing day. Buying the least expensive capital equipment in the beginning can provide a fleeting benefit, potentially causing the hardware to operate at the limits of it capacity, leading to early failure and further associated costs and downtime.

Making the right hardware choice for your particular manufacturing needs is pivotal to the success of a robotic solution within your company. Working with a qualified robotic integrator will help identify the robot system that will yield to the best ROI for your particular business.

In its simplest form, this is all about “why one type of robot will make more parts per day than another robot, even from the same suppler.” Features such as reach, payload and cycle time are just the beginning. For some operations raw axis speed may be more important.

But for those where the robot movements may not be long enough for the robot to achieve maximum speed, acceleration or the ability to make quick stops and starts may be more conducive to optimum productivity. The ability for the controller and arm end-effector combination to carry out many tasks in parallel will increase your uptime, and thus the ROI.

When robotic automation is working at peak performance, the cell is operating with minimal interruption. Selecting and utilizing the most appropriate and advanced software is the centerpiece of automation. Reliable offline programming is a key to maintaining the highest uptime level that is practical. The ability to change from task to task as quickly and simply as possible is also a high RIO influencer.

Some robotic manufacturers have recently developed PC based software that significantly reduce programming complexity and create an intuitive human machine interface, allowing for the efficient welding of a high variety of parts in low quantities.

For example, our Arc Welding PowerPac (an add-in to our RobotStudio simulation software) is a unique, geometry based off-line programming tool for generating arc welding programs. The programmer defines weld locations on the CAD geometries and the system automatically creates robot positions in relation to that geometry, including approach and departure positions. This makes it far easier than in the past for robot to go from part to part with limited pause.

The BullsEye Tool Center Point (TCP) generator and checker is another powerful automation tool that reduces downtime to almost zero. And some manufacturing software tools now have an ROI aspect embedded inside them that enables direct calculations of savings.

PROCESS AND CONSUMABLES

Choosing the right process can make a significant impact on the ROI. Should the job remain a TIG process, or can MIG or an advanced form of it be selected? Should laser cutting or welding be introduced? Can the part accommodate two wires in the weld pool for quality or speed benefits? As the list goes on, each process that is properly evaluated will give rise to a good ROI becoming a great ROI.

Another area which often surprises a new owner is the consumable side of the robotic automation. Welding and cutting each have their unique consumable requirements. Going cheap often does not provide the savings that was anticipated. Selecting an inferior consumable to save money has caused many a company expensive rework and loss of output that far exceeds their initial small savings.

WORKING WITH THE RIGHT TEAM

Selecting a robotic integrator with proven robotic welding and relationships with one or more of the prominent robotic suppliers is an important step early in the process.

As a part of your due diligence when pursuing robotic automation, a qualified integrator should provide a fully detailed and accurate simulation summary of the cell designed for your specific application. The simulation will identify all system variables and metrics, reduce your risk, confirm your intention for the equipment, and underpin your empirical ROI calculations.

Access to quality service from both the robotic integrator and the robotic manufacturer is critical. In your hour of need, how well will you be served by calling the supplier helpline? The outcome of that call could mean the difference between a mean time to repair (MTTR) of minutes, hours or days. If you can pick up a phone and talk directly with an on-duty engineer, the probability of the equipment returning to service is much improved. A very high percentage of first time fixes are made over the phone.

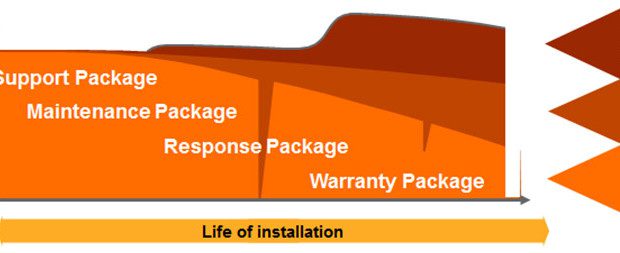

The same response is required of the parts that you may need to get up and running again. Reliable service and support is critical. Regular maintenance will extend the life of your investment. Robotic cells from leading manufacturers now have the ability to predict their own service requirement by monitoring its particular usage. This allows you to predict when service is required and plan ahead at your convenience. Poorly maintained equipment will simply cost more to run.

Knowing the variables that impact the ROI of an automated robotic system, and using this knowledge to carry out a thorough and detailed return on investment calculation prior to purchase, will provide the highest probability that the new equipment will meet, and likely exceed, your expectations. The effective ROI will act as a planning tool for both current and future expenditures, giving your company the confidence to invest in robotic automation.