Rethinking Bending Automation

Don’t attempt to adapt an assembly robot into a bending cell. New application-driven robots work alongside press brakes to simplify part programming and minimize cycle times. Instead, add process reliability enhancements and offline software and your return on investment for bending automation becomes clear and highly achievable. Here’s how to do it.

Posted: November 7, 2013

The idea of automating press brake forming operations is not new. The very earliest projects involved the relatively complex and imperfect mating of a standard industrial robot with a standard press brake machine. The results, as some manufacturers have discovered, were better on paper than on the shop floor. The difficulty of preparing the system to produce finished goods is among the many challenges of the equipment.

In general, these semi-integrated systems required a tremendous amount of time and effort to program. The robot has to be taught the programs for any new part number one step at a time with a manual control. Then the point-to-point movements must be fine tuned by an operator until a part can be completed successfully – and that is just the first headache.

The second involves getting a handle on the consistency and repeatability of the operation, so that finished products coming from the automated bending system all meet the required quality standards. If a stack of parts is not presented to the robot correctly, it will not handle them properly, leaving manufacturers with a pile of scrap parts at the end of an unmanned shift. Any mistake along the way ends with wasted time and material.

The need to enhance automated fabricating capacity has driven a tremendous amount of research and development in the design of these systems. In much of Europe, where labor and real estate costs are inherently extremely high, the drive toward adoption of all types of factory floor automation has been rapid.

In the United States the investment in capital equipment and training required to get automated bending systems up and running has prohibited many manufacturers from pursuing the technology; the motivation was not there. Changes in both the marketplace and in the technology itself are starting to alter that picture. Resurgence in the American manufacturing sector is currently taking place, driven by the economic trend “re-shoring”.

While a lot of different factors are driving this trend and a lot of opinions are out there about what it means, credit must be given to U.S. manufacturers for rolling up their sleeves and deciding to meet the challenge of low cost competitors head-on. They achieve this by striving to eliminate waste; seeking efficiency improvements no matter how small or obscure; focusing their efforts on quality and flexibility; and by integrating automated processes wherever possible. At this junction the automated bending cell re-enters the equation.

Advances in the bending cell design standards were necessary in order to address the major headaches involved with early bending automation. First, the time consuming hands-on way of teaching robotic systems needed to be replaced by offline 3D simulation software. Now, new part numbers can be programmed for the cell without tying up the equipment, allowing more continuous production. Offline programming software also enables visualization of complex bending programs, reducing the time to get from CAD file to prototype to production. It drives down the required lot sizes for justifying the cell, and keeps the equipment occupied so it can generate product.

The second dilemma, making the automated process reliable, involves creating tight integration between the robot and press brake. A few different technologies are available to tackle this issue.

Squaring stations are used to orient every blank a robot handles before bending. The robot retrieves a part from a general loading stack which does not have to be perfectly positioned and brings it to a special station to square up two known edges on the part. From there, the robot can accurately handle the blank. Although this increases part handling reliability, it also adds to the cycle time for every blank. In addition, complex part shapes are still challenging.

A more advanced approach is to equip the cell with a part detection camera. A high-resolution CCD scans the loading stack and adjusts the robot to the position of the next blank in just a few seconds. The very precise image is compared directly to a CAD file stored in memory, allowing complex part shapes to be located easily.

A second layer of process reliability occurs at the press brake itself. Sensors on the back gauge fingers confirm that a part has been positioned correctly for bending. If the robot has somehow mishandled a part, the back gauge sensors form a final line of protection against scrap parts. If the part being bent is not pressed into the right position against two independent sensors, the machine does not attempt to bend the part. Instead of bending a run of parts with crooked flanges, the system is interrupted. An automated system without these sensors cannot be considered reliable enough for precision sheet metal parts.

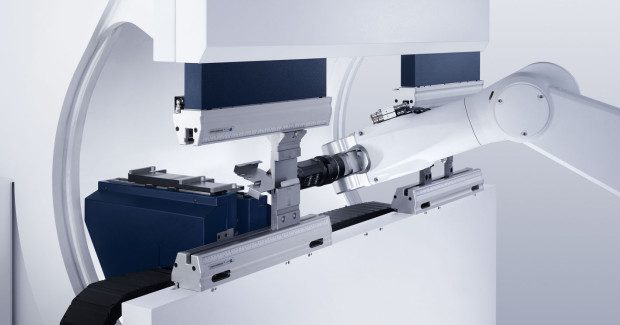

Key technologies such as these have gone hand-in-hand with the development of new robots which are dedicated to bending operations. Instead of adapting a robot designed to assemble automobiles into a bending cell, the robot’s axes and travel motions are purpose-built to work alongside a press brake.

These newer designs are application-driven to simplify the task of programming parts and to minimize part cycle times. A specialized robot, along with the process reliability enhancements and offline software, constitutes a fully integrated bending automation cell. This all means the return on investment for bending automation is now clear and highly achievable in the production environment.