Innovative Welding and Safety Technology

Miller Electric showcases their PipeWorx FieldPro™ System for onsite Stick, TIG, MIG and Flux-Cored pipe welding in the refinery, petrochemical, power generation and HVAC industries, and a new hard hat option for the Miller Powered Air Purifying Respirator (PAPR) line has been paired with the company’s Titanium Series™ auto-darkening welding helmets.

Posted: November 16, 2013

Miller Electric Mfg. Co. (Appleton, WI) offers their latest and most innovative welding technology and safety accessories that help increase productivity, reduce costs and improve quality across applications associated with the fabrication, construction and manufacturing industries.

Live welding demonstrations of solutions from ITW Welding companies’ Hobart Brothers, Bernard and Tregaskiss will be used at Fabtech 2013 with premium Miller equipment. Miller welding representatives will be available to answer product and welding questions.

Miller has several new products, including the PipeWorx FieldPro™ System for onsite pipe welding in the refinery, petrochemical, power generation and HVAC industries. It offers traditional Stick, TIG, MIG and Flux-Cored welding processes. It can also provide advanced Regulated Metal Deposition (RMD®) and Pulsed MIG processes with the addition of the FieldPro Smart Feeder.

The PipeWorx FieldPro System provides advanced remote control capabilities that eliminate travel to and from the power source, optimize productivity and simplify process changeover. The system also simplifies cable management by eliminating all of the communication cables that cause clutter and hassle on the job sites. It features controls that are labeled in common welder terminology to make it simple and intuitive to use.

The PipeWorx FieldPro™ System for onsite pipe welding in the refinery, petrochemical, power generation and HVAC industries comes with traditional Stick, TIG, MIG and Flux-Cored processes, and can run the Regulated Metal Deposition (RMD®) and Pulsed MIG processes with the addition of the FieldPro Smart Feeder.

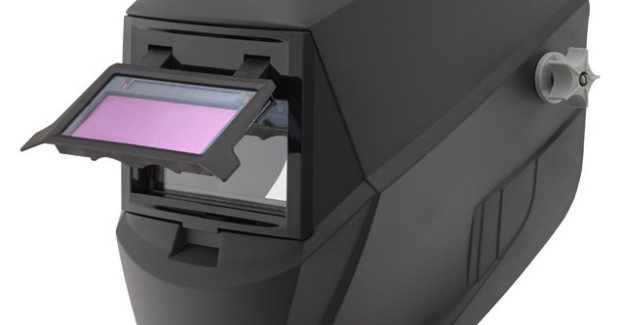

The Classic VSi and the Classic FS #10 2×4 Flip-Up welding helmets are the newest additions to the trusted Miller Classic Series. These helmets provide a cost-effective alternative to welding operators who have previously used passive lenses and are looking for the performance and flexibility of an auto-darkening helmet.

The helmets offer new flip-up design features that allow the welding operator to grind and carry out other tasks without raising the welding helmet or switching over to a dedicated grinding mask — saving time and ensuring consistent protection of the face.

Miller Classic VSi, Miller Classic FS#10 Flip Up

Booths N-1136, N-836: The Classic VSi (left) and the Classic FS #10 2×4 Flip-Up welding helmets from Miller Electric.

A new hard hat option for the Miller Powered Air Purifying Respirator (PAPR) line has been paired with the company’s Titanium Series™ auto-darkening welding helmets. These helmets feature exclusive InfoTrack™ digital lens technology, while the PAPRs provide excellent respiratory protection from hazardous welding fumes found in some welding environments.

The hard hat option is ideal for welding applications in construction, manufacturing, pipelines, shipbuilding and other industries where hard hat use is required. [email protected], www.millerwelds.com