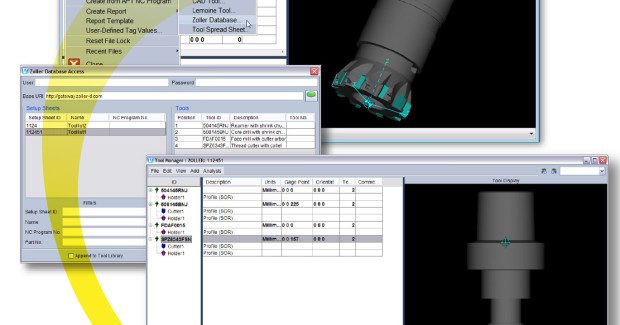

Direct Interface Between CGTech and ZOLLER TMS Tool Management Solutions

CNC verification and simulation software developer CGTech and ZOLLER, a presetting and measuring machine manufacturer, announce a newly developed tooling management interface that increases overall machining effectiveness by reducing the operating costs in tool presetting, simulation and prove-out.

Posted: October 21, 2013

Direct interface between CGTech Zoller and ZOLLER TMS Tool Management Solutions.

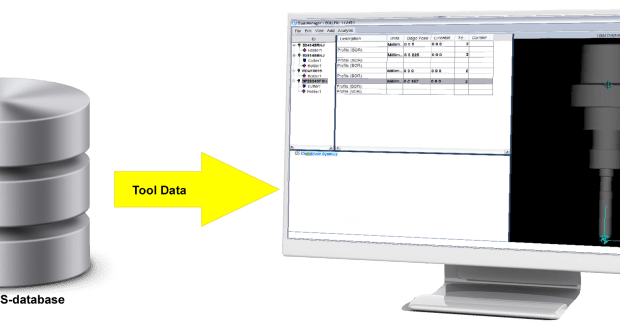

The ZOLLER database provides tool data (geometry) to the simulation system.

CGTech (Irvine, CA), the developer of VERICUT CNC verification and simulation software, and ZOLLER (Ann Arbor, MI), a leading presetting and measuring machine manufacturer and expert in the field of tool management, have announced a new product to better serve the customer base of the two companies.

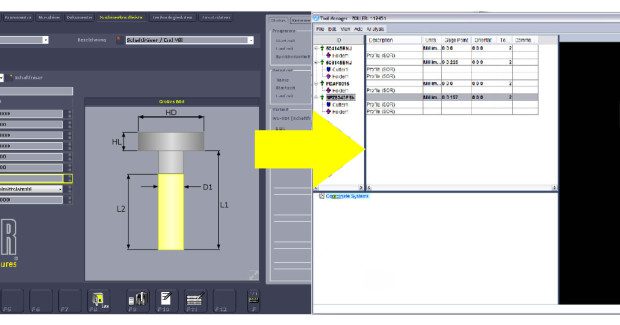

“Our interface to the ZOLLER TMS Tools Management Solutions provides a direct link between VERICUT and TMS,” said CGTech Product marketing manager Bill Hasenjaeger. “A complete set of cutting tools for a job are quickly and easily transferred from the ZOLLER TMS database to VERICUT.”

VERICUT simulates CNC machining to identify errors in the NC programs (such as collisions, over-travel, gouges, etc.). Using the software, manufacturers can verify the accuracy of the program before it is loaded on the machine, thereby reducing or eliminating the need for time-consuming manual prove-outs. VERICUT also improves machining efficiency by optimizing cutting speeds.

“ZOLLER TMS Tool Management Solutions combines cutting tool information provided by cutting tool suppliers as well as actual physical tools that are scanned thru the ZOLLER presetter and measuring machine product line in 3D,” said Zoller president Alexander Zoller. “The user will benefit from a single source database for programming and simulation.”

www.cgtech.com, www.zoller.info.usa