FILL THE GAP: ROBOTS FOCUS ON QUALITY

Though many might argue that the progression of robotic welding technology has always focused on profit, Heath Suraba of Lincoln Electric explains why you must have quality before you can realize profit.

Posted: October 1, 2013

When you hear someone talk about robotic welding what images appear in your mind? In my mind’s eye, I see welds being laid down with perfection. Do you know the type of perfection I’m talking about? Maybe you do, maybe you don’t. Maybe you don’t care.

I can tell you that as every year goes by, the welding industry in this ever-advancing world is using robots to focus on quality. There are good reasons for this perfection: servo motors, encoders, processor control, welding power sources that have been “thoroughbred” over the past 15 years to perform flawlessly in high-speed robotic welding applications.

This constant progression of robotic welding technology has always had one common goal, that, if you break it down to its purest form, is quality. Many would disagree, saying its focus is on larger profits. Yes, that’s important; however, you must have quality before you can realize profit.

Consider this: Is it more profitable to have a part that’s welded consistently or inconsistently? Is it more profitable to have less rework or more rework? I have been doing this for a long time, and in absolutely every application I have ever worked on, no one has ever said “Hey, let’s weld this with a robot to make money, but let’s do it with less quality.” The focus, above all else, has always been quality.

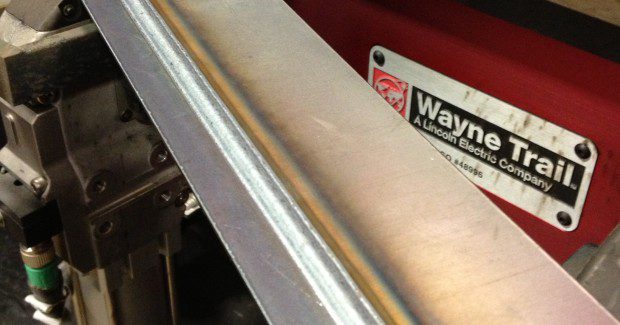

This custom robotic welding system consists of a FANUC six-axis robotic arm and controller, powered by a Power Wave® 455M. The system includes several subassembly fixtures and one final assembly fixture. It now takes the robotic cell just 39 minutes to weld the frame. Add in the fixture change out and final assembly, it takes less than two hours to complete the center and rear sections.

Industry demands more quality and less rework. The go-to tool to achieve those goals is robotic welding. Once a company discovers robotic welding, they never look back. Welding robots make the same repetitious welds over and over again without complaint at the same exact parameters and speed all day long. Every day they show up for work producing and never get tired, all the while doing the exact weld the same way as the day before. Skilled workers are hard to come by these days. Robots fill the gap.

The welding power source has the ability to monitor welding quality. Millisecond by millisecond, it records welding parameter data and compares that data against a model weld that you taught it through programming. If the weld characteristic falls outside acceptable limits the robot is alerted, the failure is recorded. If desired, email alerts can be sent out from your welder to dispatch weld techs to resolve the issue (yes, your welding power source can be connected to the Internet, cloud or internal network).

Some welding companies offer this technology inside the welder for free and are available for everyone to use. Not to mention it’s quite simple to set it up. The welding power source can also track wire consumption so as to prevent running out of wire in the middle of a weld.

In my experience, running out of wire in the middle of a part being welded was one of my biggest fears and cost me many a night’s sleep. All too often the operator or weld tech would inadvertently place the unfinished part in the finished bin not realizing it had missing weld or a partial weld.

So what exactly makes welding with a robot so great? Well, for starters, it only does what you tell it. That’s a pretty nice deal if you ask me . . . have you ever told some person to do something, and they kind of take an “artistic license” and do what they think is better or “easier?” In some cases the quality could potentially turn out to be less than desirable. Many companies have been “asked” by their customer to use robotics or face losing work due to inconsistent quality.

Automation is an enabler. For instance, let’s say you need to weld 10,000 parts. A robotic welding cell could weld the parts at a rate magnitudes greater than a person could manually, with better quality and less rework. Keeping in mind that a person, unskilled at welding but trained on weld inspection, would be unloading the welded part and loading the parts to be welded. A welding robot takes on the burden of tedious, repetitive jobs easily and frees up the skilled welders to work on complex weldments that are not suitable or cost effective for robotics.

So, maybe next time you consider the welding process on your production floor, put some thought into what it would take to do it robotically. See where your quality and rework numbers are now and imagine what they could be like by adding the consistency of automation.