Advanced Surface Moldmaking

Theory becomes practice with the latest CNC technologies in your shop.

Posted: October 24, 2013

Last month we looked at Cycle 832 for compile cycles, residual material detection and collision avoidance as one of the latest advancements for machining. This time, in a related development, we’ll examine the advanced surface innovations that complement Cycle 832, although they are capable of completely independent functionality.

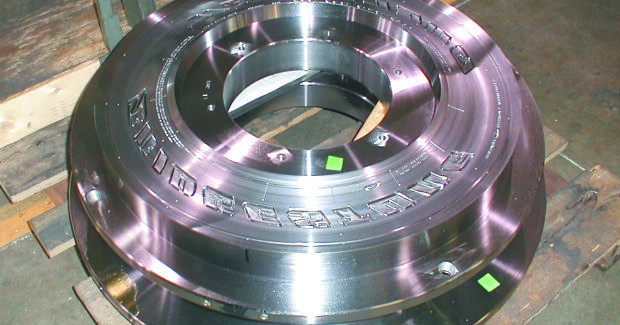

With dyne roughing, dyne semi-finish and dyne finish commands, 3D free form surfaces are machined much faster and more easily on today’s advanced CNC. While not an essential for straight 2D hole-making in the mold process, this new function has particular advantages for the 3D world in aerospace and especially medical mold and die work, including 2-1/2D work with a constant Z-axis.

The splines and curves on more complex shapes and pockets require an advanced compressor function, as do the tight tolerances when high-speed machining, acceleration/deceleration cells and jerk limitations are involved. The neat thing about this new advancement is that you can “see” the tolerances in a high-speed mold view on the screen of the CNC or offline on a trainer. This allows checking all the travel points, plus part surface quality, part whip out, over travel etc.

In the more advanced training modules, the PC-based verification software simulates the actual control function on the machine to do this work. The reduction in crashes, bad parts and material scrap alone will impress programmer and shop owner alike.

http://youtu.be/bBm9grxC1cc

The mold making view allows the visualization of the CNC processing paths of large part programs, e.g. from CAM systems. By means of the mold making view, you can get a quick overview of the cnc program, e.g. the shape of the workpiece or traversing errors or check approach and retraction paths.

When using G-code dyne commands, there’s another advantage. Typically, G-code standards only spec feed commands; that is, not the precise three-decimal codes or canned cycles, but only the motion. Using dyne commands for programming advanced surface conditions takes the mold-making process to a new level. This development requires a rather steep learning curve, which some will grasp quickly, while others will need more practice or even a step-by-step training class. I know, because I conduct such training sessions all the time nowadays.

The other recent improvements in spline functionality, swivel cycle and especially the new generation of transformation orientation with nodding compensation, where the position of the part relative to the tool tip is key, all have significant benefits to the aerospace and medical mold worlds. Completing this picture, the safety integrated functions and the critical program protection afforded users by Linux-embedded vs. Windows-based programs have combined to provide users much greater accuracy, speed and protection of the critical part geometries involved in these market segments.

Functionally, the USB transfer from a programmer to a machine, from machine to machine and even onto a network, with full cut-and-paste flexibility, editing onscreen, transfer in OR out, plus the network sharing of all changes has put the most advanced CNC technologies at the ready to handle the most challenging of jobs in the specialized job shop or OEM production department.

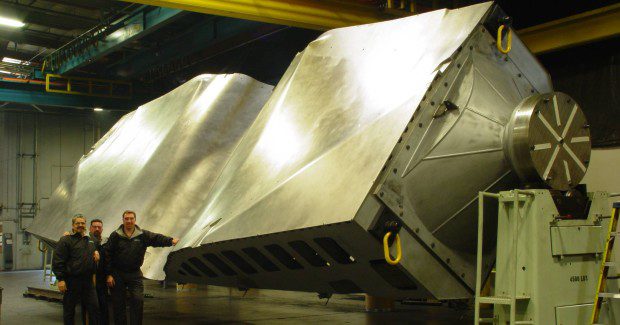

A final advancement is the control’s ability to “see” the advanced surface requirements of the most contoured workpiece, pocket or spline configuration as a Flat Stanley, if you know that series of kids’ books. Of course, the technical explanation is that the cylindrical transformation of the CNC allows the control to literally “wrap” the commands around a rotary axis in an entirely new fashion, once again resulting in faster programming, faster processing and greater accuracy with no compromise on the part quality and a surface finish beyond all previous generations of CNC. Hello algorithms, goodbye chatter.

This is one of the most fascinating developments in my nearly three decades of work in CNC, and I’d be happy to discuss it with you anytime.