Common Shielding Gases Used for Arc Welding

The variety of shielding gases used in arc welding can be confusing as to when to use which gas for which application. Here are some basic guidelines to follow.

Posted: August 7, 2013

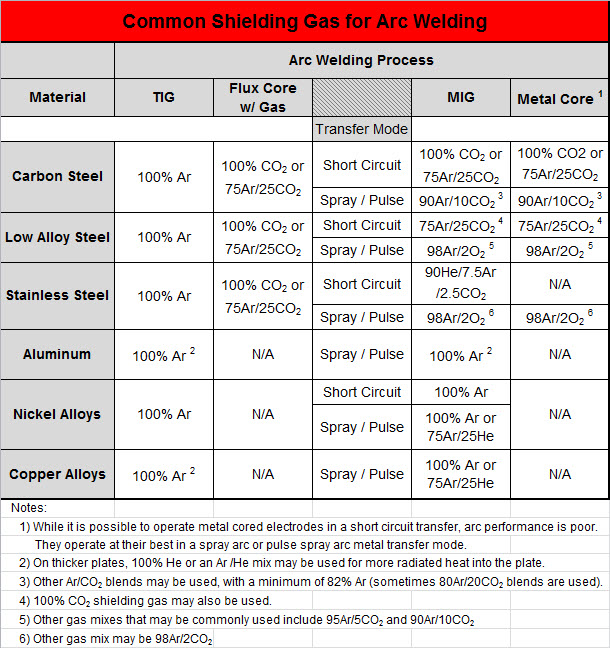

Table 1 is a summary of common shielding gases used for the main arc welding processes by base material type. In the case of the MIG and metal core processes, it also identifies shielding gases depending on which mode of metal transfer is being used.

(Click on table to enlarge it)

Tom Myers

The Lincoln Electric Company

"Shielding gas can increase the smoothness of the arc and operator appeal, but they also increase the complexity of welding equipment and the need to change the type of shielding gas when welding on a different type of material and/or with a different arc welding process. In some cases, different shielding gases can be used with the same process and material, each with its own benefits."

(Click on photo to enlarge it)

Each gas has different properties that affect how it responds under the heat of a welding arc, include its reactivity, ionization potential and thermal conductivity. Reactivity effects whether or not a certain gas or gas mix can be used with certain materials. These properties also affect various shielding gas operating characteristics and effect bead shape and penetration profiles.

(Click on photo to enlarge it)

Q: I am an Agricultural teacher and will be teaching a section on arc welding for the first time next year. There are a variety of shielding gases used in arc welding, and I always have been confused as to when to use which gas for which application. Please give some guidelines on this topic.

A: The variety of shielding gases used in arc welding indeed can be a confusing topic. However, the use of an external shielding gas is a necessary component for some processes, as it is a requirement for surrounding and protecting the arc and molten weld metal from contamination by the atmosphere.

Shielding gas can also increase the smoothness of the arc and operator appeal. But, they also increase the complexity of welding equipment, with the addition of a gas cylinder or bulk gas supply and the necessary gas apparatus (i.e., regulator/ flow meter (or flow gauge) and gas hose. Not to mention the complexity of needing to change the type of shielding gas when you need to weld on a different type of material and/or with a different arc welding process. In some cases, different shielding gases can be used with the same process and material, each with its own benefits.

Some arc welding processes do not use an external shielding gas; they instead provide their own shielding system, via slag coverage of the weld and gases produced from chemical reactions in the arc. These include the Shielded Metal Arc Welding (SMAW) process, Self-Shielded, Flux-Cored Arc Welding (FCAW-S) process and Submerged Arc (SAW) process. The main arc welding processes that do require an external shielding gas are the Gas Tungsten Arc Welding (GTAW) process (aka TIG), Gas Metal Arc Welding (GMAW) process (aka MIG), Metal Cored Arc Welding (GMAW-C) process (aka metal core) and Gas-Shielded, Flux-Cored Arc Welding (FCAW-G) process (aka flux-cored with gas).

The variety of shielding gases used with these processes is large, particularly with binary blends and ternary (three-part) blends and the percentages of each gas type in the blend. In addition, gases can vary depending on the region of the world where you are welding. Therefore, to simplify this article, we will only discuss the most common shielding gases used in the U.S. welding market.

The most common shielding gases used for these main arc welding processes include argon (Ar), helium (He), carbon dioxide (CO2) and oxygen (O2). While Ar, He and CO2 may be used by themselves (i.e., 100 percent) for certain applications, in other cases the four gases are mixed together in different combinations to form shielding gas blends.

These blends are expressed as a percentage (e.g., 75 percent Ar/ 25 percent CO2 or 75Ar/25CO2). Sometimes they are even expressed in shorthand terms, such as “75/25”. However, this is making the assumption that it is known which two gases the percentages are referring to (and they are not always the same, as is the case, for example, with 75/25 for carbon steel and 75/25 for nickel alloys). Each of these gases has different properties that affect how they respond under the heat of a welding arc. These include their reactivity, ionization potential and thermal conductivity. Reactivity effects whether or not a certain gas or gas mix can be used with certain materials.

These properties also affect the various shielding gases’ operating characteristics, as well as effect bead shape and penetration profiles. A detailed discussion of each of these properties, as well as the attributes of each shielding gas and gas mix, is beyond the scope of this article. However, detailed information on shielding gases can be found in Lincoln Electric’s “GMAW Welding Guide” (booklet C4.200) on pages 12–15. It is available at no charge on their website by clicking here.

Table 1 summarizes common shielding gases used for these main arc welding processes by base material type. In the case of the MIG and metal core processes, it also identifies shielding gases depending on which mode of metal transfer is being used. Footnoted are common alternative gases. This table is not meant to be an exclusive list of shielding gases used for arc welding. Other gases (e.g., hydrogen) and many other gas mixes of different percentages and combination of gases are also used in the welding industry. Table 1 is simply meant to be a quick summary of the most common gases used for common types of base materials in the U.S. welding market.