Boosting Machine Tool Efficiency: How to Integrate Automated Machining Systems

Despite the benefits of automation, its complexity can intimidate first-time investors. Shops must learn how to effectively define, plan, justify, select, implement and execute a full system integration. To do this, they should become familiar with the process and the key considerations needed for a seamless integration.

Posted: August 12, 2013

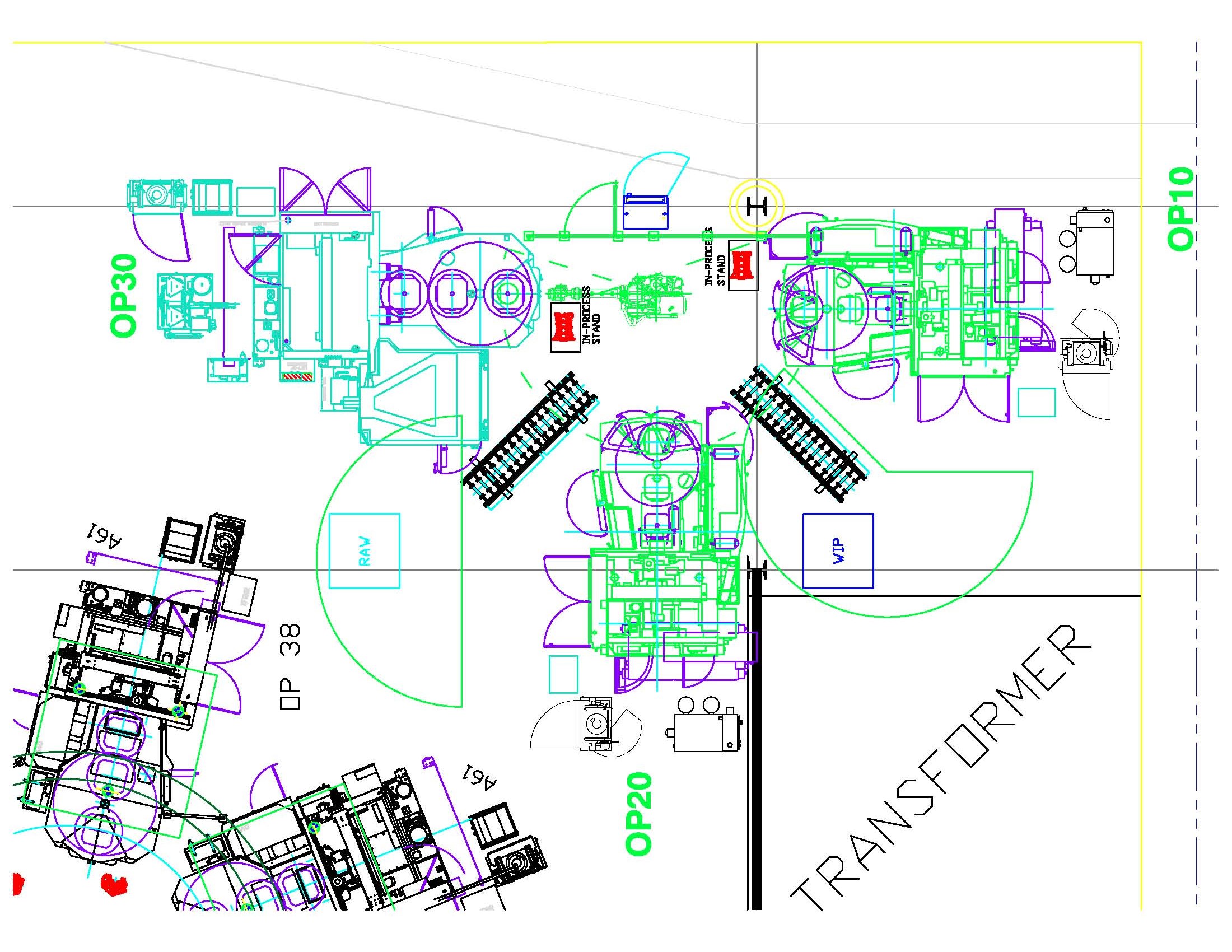

Floor plan layout of multi-operation machining cell. Depending on an individual shop's needs, automated cells can be designed for end-to-end part production or specifically tailored to specific operations.

(Click on drawing to enlarge it)

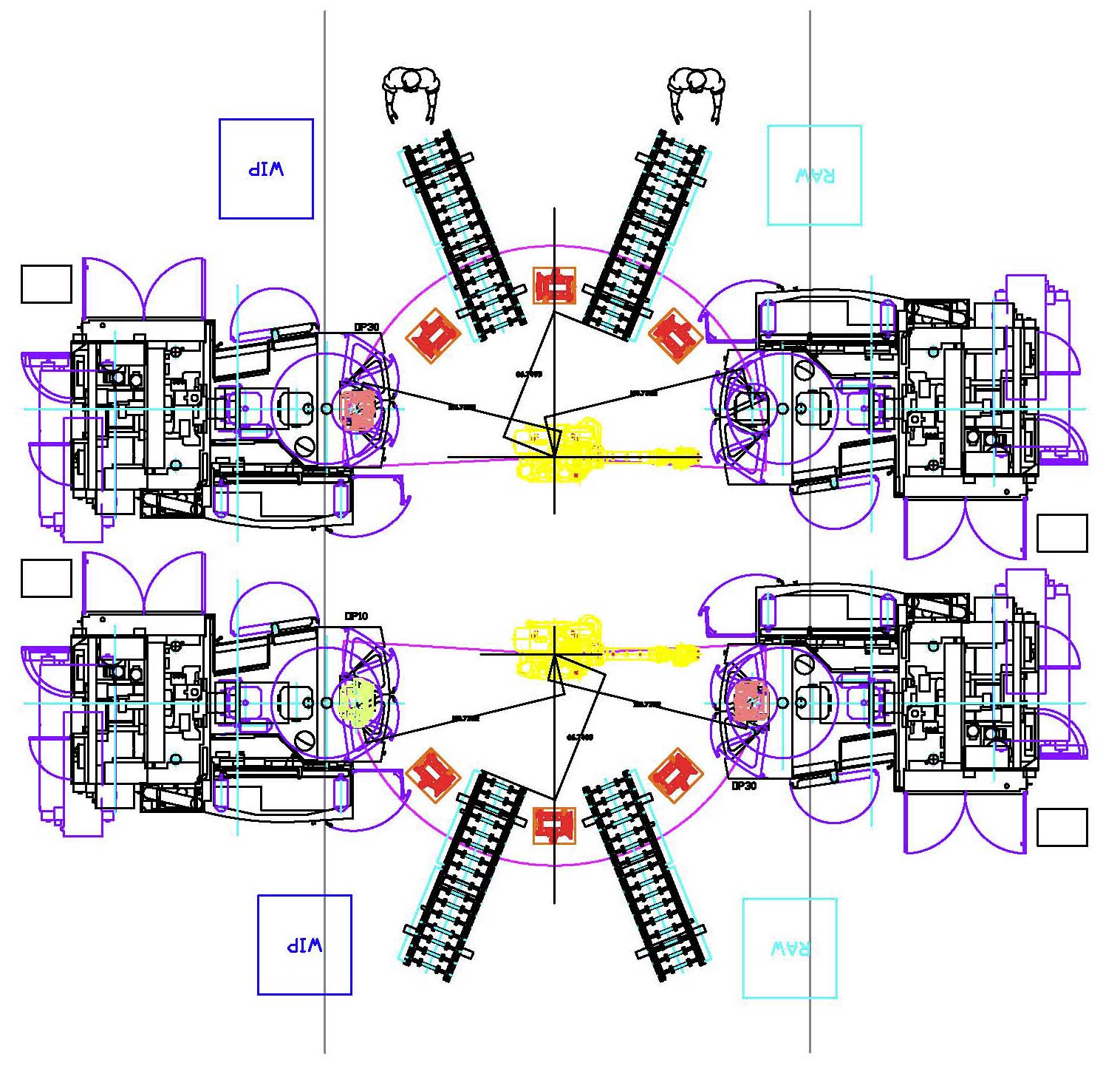

Floor plan layout with workflow. Proper cell planning enables the shop to efficiently manage its production workflow.

(Click on drawing to enlarge it)

A robot-tended sinker EDM cell with automated load/unload of tooling and workpieces.

(Click on photo to enlarge it)

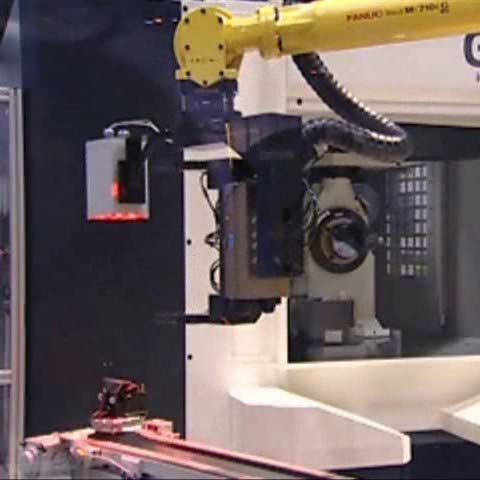

Single-source suppliers are an excellent resource for seamless integration from planning to process engineering, and final installation.

(Click on photo to enlarge it)

A completed gantry robot cell and system for repeatable volume production.

(Click on photo to enlarge it)

Aerospace part production in an MMC-R fixture plate distribution system.

(Click on photo to enlarge it)

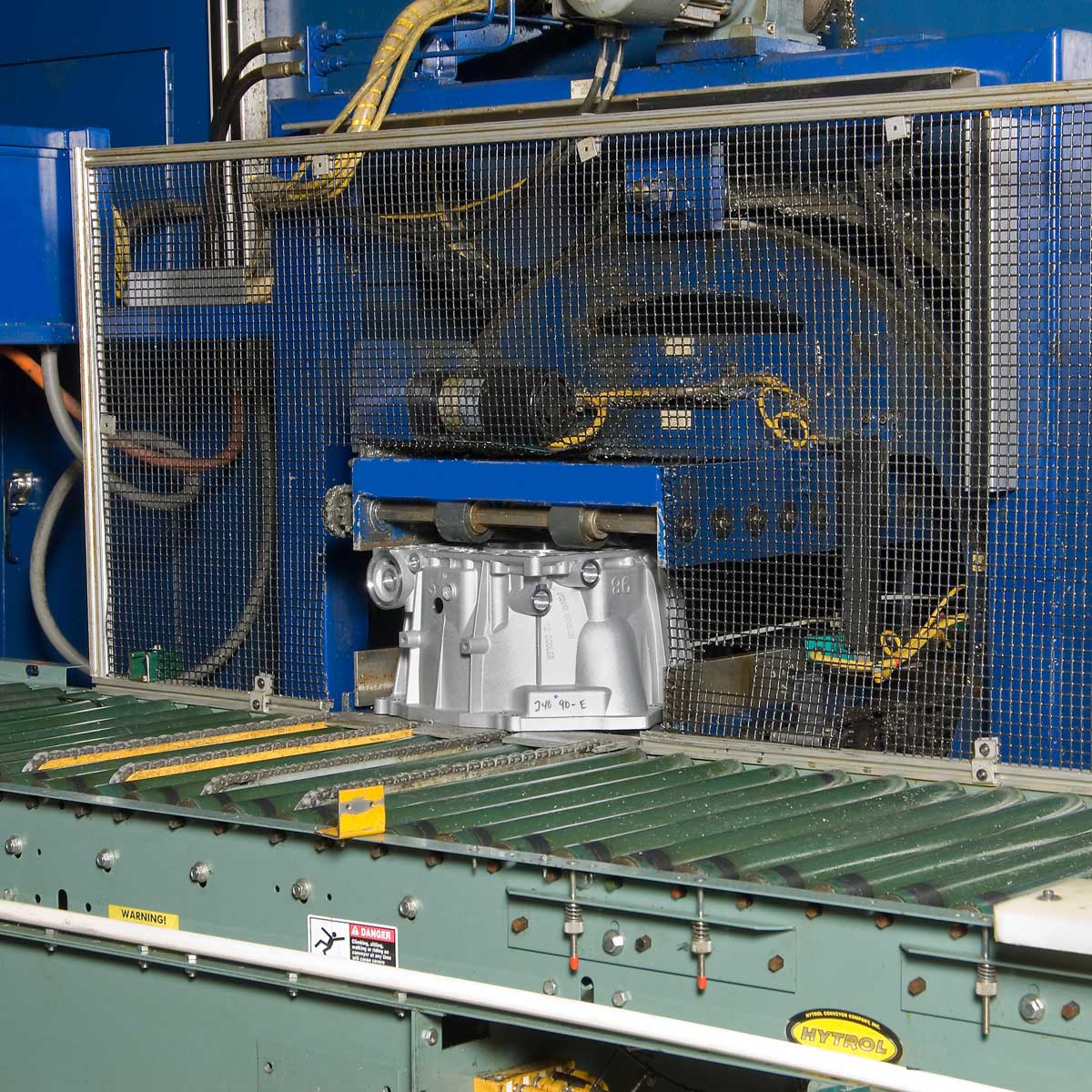

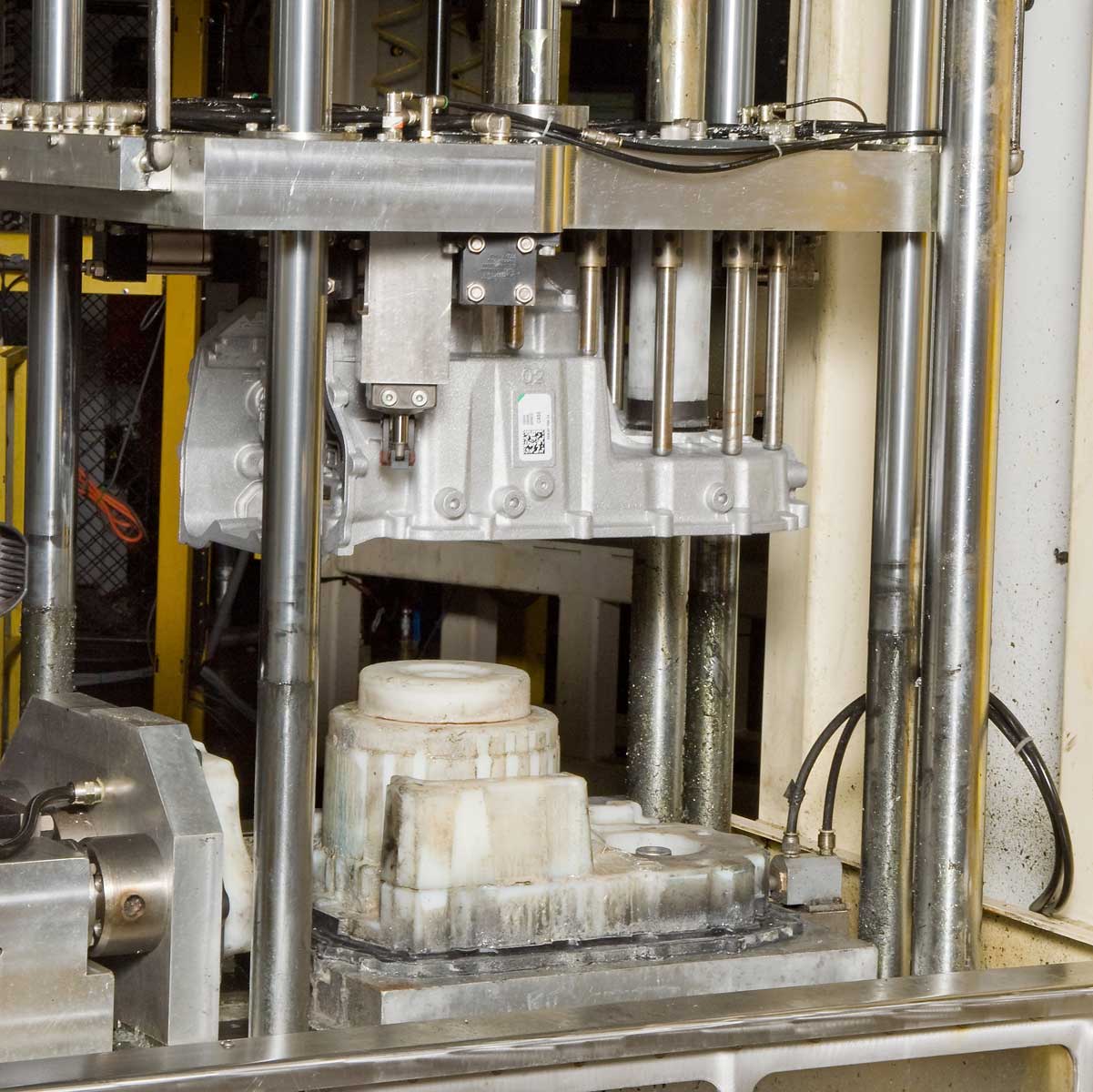

A high-volume automotive engine block production cell with robot management and vision system.

(Click on photo to enlarge it)

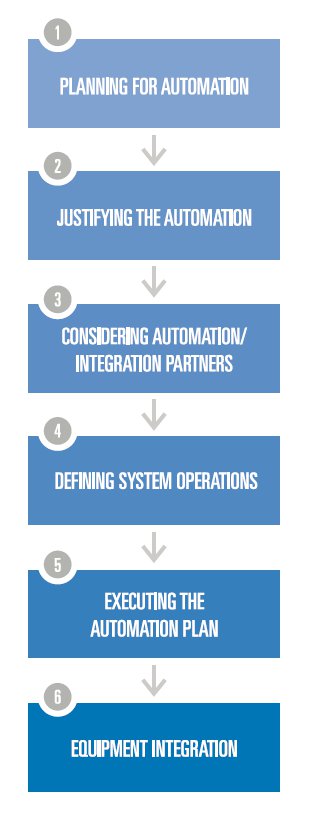

The Integration Process. This planning process helps shops identify what they would like to accomplish through automation in order to determine how their system should best be configured.

(Click on illustration to enlarge it)

(Click on photo to enlarge it)

Automated technologies and auxiliary processes.

(Click on previous eight photos to enlarge them)

Early in the project, be sure to determine the criteria used to accept the automated system. All of these expectations should be dealt with in the vendor agreement to ensure success down the road.

DEFINING SYSTEM OPERATIONS

Once the internal and external partners are identified, planning can begin for the operation of the automated system. This step needs to be a collaborative process involving all parties. First, some considerations surrounding cell layout must be verified. The automation cell should be designed in a way that optimizes the use of floor space. The flow of material through the cell must also be decided — such as where the raw material is introduced into the cell, and the location for the finished product.

Specifications for the production volumes should be known, as should requirements for additional capacity. If additional capacity is a possibility, a plan for future expansion should be in place. This plan should include the needs for future machining centers, material handling and additional part types. If an operator is no longer standing at the machine(s) as a result of unattended operation, then the machines should use machine processing monitoring functions, such as tool-life monitoring and tool-breakage functions. With these monitoring functions, the machining equipment could detect when a tool is becoming dull (reached the end of its life), and if a tool has broken during the machining process.

Many shops employ other functions, such as part probing, to monitor the process and to find the exact location of the part before the machining process begins and to use part-seat detection to ensure that the part is loaded properly in the fixture. Both help to ensure the automated system is producing quality parts. In an unattended environment, process checks should be conducted to manage the quality of the part. If the process is capable enough, a company can ultimately reduce its costs on part inspection within the automated system. It must be determined how often inspections take place, and on how many parts (i.e., will there be automated inspection checking on every part, or just some parts?).

Individuals should be identified who will understand and maintain this process. They must know how parts are rejected from the system, and be familiar with the process in which operators are notified (and how quickly they react) if something goes wrong. The company should have a plan on how scrap is identified, tracked and quarantined within the system. Standards must be defined concerning the restart of the machines after interruptions to the production processes.

Scheduled maintenance should always be part of the plan to support an automated machining system. Checks should be conducted periodically to verify that the process is still within specification and that the parts coming off the machine are of good quality. It must be decided if operators should perform these checks while the machine is online or offline, and if they are going to be manual or automated checks. Other questions to ponder involve the use of various automation technologies and auxiliary processes are noted below:

- How is the work going to be transferred within the cell? Will it require a pallet-handling system, or will parts be handled directly by the automation?

- Will quick changeovers be a factor? Is standardized fixturing necessary?

- Are robotic vision systems required for part inspection, loading/unloading and/or identification?

- Will parts need to be automatically marked, identified and tracked?

- Is it critical for parts to be cleaned before leaving the cell?

- Will secondary operations such as deburring be an automated feature managed robotically?

- Is online inspection necessary to ensure the quality of all parts leaving the cell?

- Is a robot gripper quick-disconnect mechanism necessary for handling multiple part/pallet types?

EXECUTING THE AUTOMATION PLAN AND INTEGRATION

This first step in executing the automation plan should be a detailed review of all project designs, preferably using the benefits of solid modeling design tools. All approvals must be coordinated so that when a change is made to one design (a robot gripper, for example), the other designs for the tooling and equipment within the automation system are checked for possible effects by the design change (such as the machine fixture).

When a single-source supplier is employed, that supplier is responsible for ensuring these checks of the designs are completed, eliminating potentially excessive delays to complete the overall design checks. Throughout the project, predetermined milestones should be in place to confirm tasks are progressing as they should. Early on, the program manager/coordinator/leader should be identified. This is the person who sets the milestones, coordinates the on-time delivery schedule of multiple suppliers, and takes ownership and ensures that the milestones for on-site installation are reached.

Sometimes, the end-user may not be able to assign a dedicated project manager who coordinates these activities, simply because there aren’t any personnel with the time available to take on these extra tasks. If a single-source system supplier is used, the supplier determines the milestones for progress and is involved in all aspects of the project coordinating multiple suppliers on site and making sure everything shows up and is installed on time.

Good supplier relationships are key to successful installation, and many times the suppliers on the project appreciate a single project manager and respond more quickly to a designated project manager. Prior to installation, all members of the integration team should know when each component is scheduled to arrive, and where these components are to be located on the shop floor. This coordination surrounding the delivery of equipment for an integrated/automated system is required for the machining centers, machine fixtures, robots, conveyors, etc.

Delays in delivery for even one piece of equipment could affect the installation/integration of other system components into a complete system or cell. For example, if the machine’s fixtures are late, the robot can’t be programmed. Handling such logistics can be a daunting task, but with a single-source supplier, the scheduling and execution of the program can be better managed and coordinated.

During the installation of the automated system, it is critical to involve all internal resources in the installation — including the engineers, maintenance personnel and operators. Everyone should obtain as much experience as possible while the supplier’s installation team is on site. Adequate training should be conducted in order to review operations, maintenance and troubleshooting, which are all important to the future success of the automated system. A specified acceptance test run should be conducted along with a complete functional check of the automated systems. It should be verified that the full capabilities required are in place and that no weak points exist.

Once the start-up has been initiated and production begins to ramp up, it is a good idea for local personnel to continue to familiarize themselves with the operation of the automated system in order to provide support for continuous improvement of the system. Learning how to maximize equipment efficiencies increases the future success of the system, so it must be ensured that all aspects of the project are moving as they should be. Once complete, a final acceptance review should take place.

If the supplier has guaranteed a throughput or takt time on the automation system, a throughput test should confirm the automation system is performing per the requirements. The end-user should examine the warranties provided with the system with those suppliers responsible for supporting those warranties. Supplier expectations for the final aspects of the program installation and startup should be communicated and understood by all parties at the beginning of the project — especially those expectations surrounding the level of assistance the supplier(s) should provide after acceptance of the system.

Machine efficiencies for manually operated systems are typically around 85 percent utilization, while the machine efficiencies for an automated system are typically above 90 percent, approaching 95 percent utilization. Machine counts required for known part production volumes may be reduced due to the increased efficiencies realized from automated systems. Post-installation, it’s very important to have proper documentation in place to maintain and support the system. A spare-parts inventory should be identified, and preventive maintenance schedules should be maintained to keep machines operating at peak efficiency.

ADVANTAGES OF AUTOMATION

Businesses that have employed automation systems typically enjoy many efficiencies. First are the reduced manufacturing costs that result from lower direct labor costs. Robotic automation enables a single operator to more efficiently handle several machines at once. Machine efficiencies for manually operated systems are typically around 85 percent utilization, while the machine efficiencies for an automated system are typically above 90 percent, approaching 95 percent utilization. Machine counts required for known part production volumes may be reduced due to the increased efficiencies realized from automated systems.

Ergonomic issues that result from workers carrying heavy parts can also be addressed with automation. There is increased flexibility of shop resources, with production hours rising through unattended machining, or with 24/7 operation. For job-shop types of environments — which have many part types and low part counts — automated systems often bring higher productivity due to the faster part turnaround resulting from the elimination of direct setups on the machines.

With less time between part setups and multiple jobs running concurrently, there is more throughput generating additional revenue. Customers enjoy shorter lead-times. Ultimately, the business is able to react quickly to market opportunities and can better compete globally due to reduced labor and part expenditures. Increased revenue potential also comes from additional machining capacity. Imagine the profitability potential if the machine utilization is improved by only one hour a day. While the number sounds small, it can have a significant impact on the shop. For example:

- The business sells its machining time at $75/hour and has 250 days a year in available production.

- It increases production time by one hour/day.

- This extra hour per day yields potential additional annual revenue of $18,750.

With the shop running more efficiently, the business is able to accept more jobs and diversify applications. Because the company can do a better job of tracking the work that comes through the shop with an automated system, the machines can run faster, longer and with improved turnaround. A shop that was reorganized for improved tracking and flow of work can also see a more efficient manufacturing process.

Finally, many customers also have an improved perception of the business when it employs state-of-the-art machining. Modernization through automation shows a company’s commitment not only to their customers’ growth, but also their own.