What You Must Know About Pulsed MIG Welding of Aluminum

Three manufacturers share their tales with Mike Vandenberg, Jeff Herb and Chris Roehl of Miller Electric about pulsed MIG welding of aluminum and how new technologies have made the process more viable in their operations by reducing distortion and rework, improving productivity and standardizing wire size.

Posted: May 28, 2013

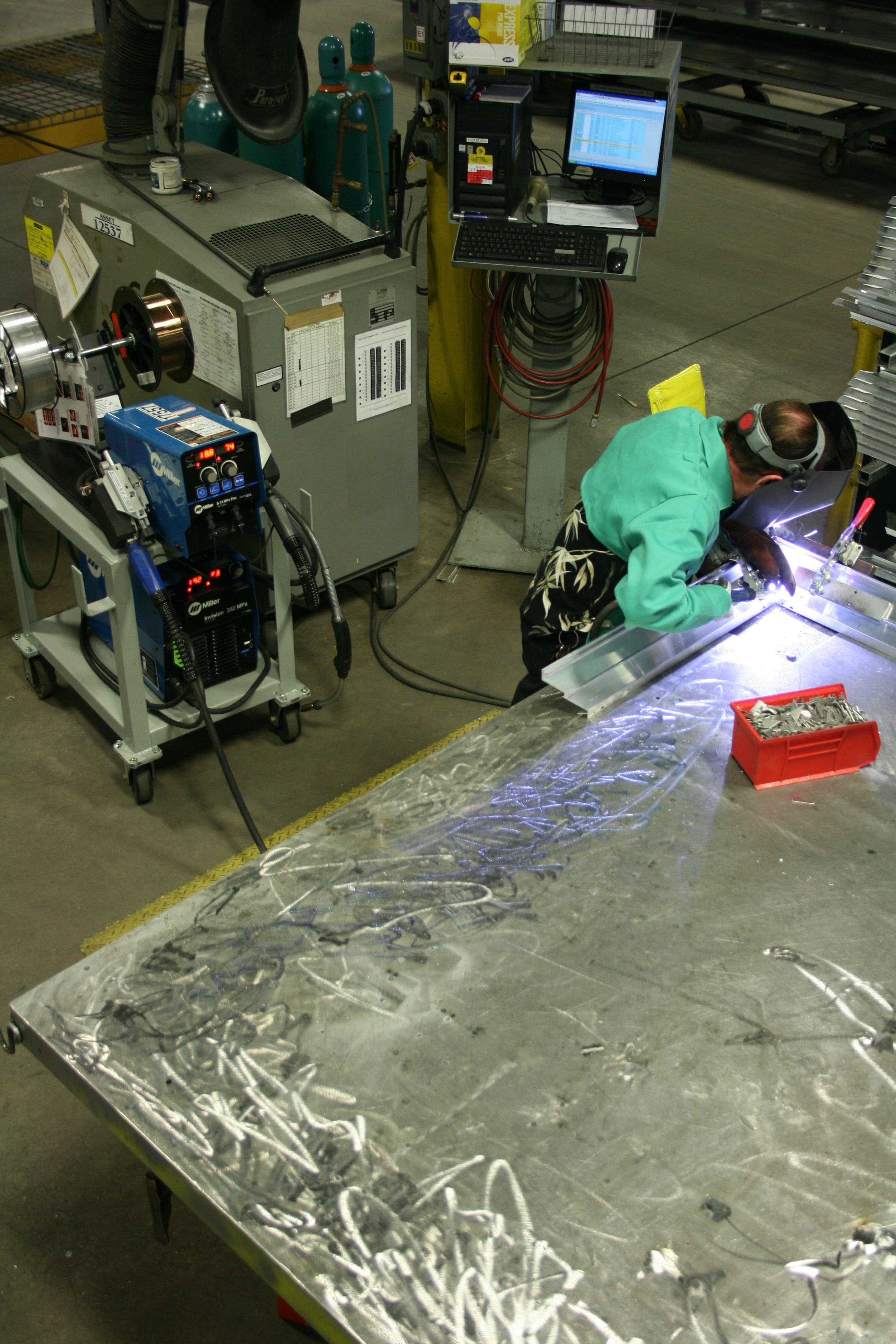

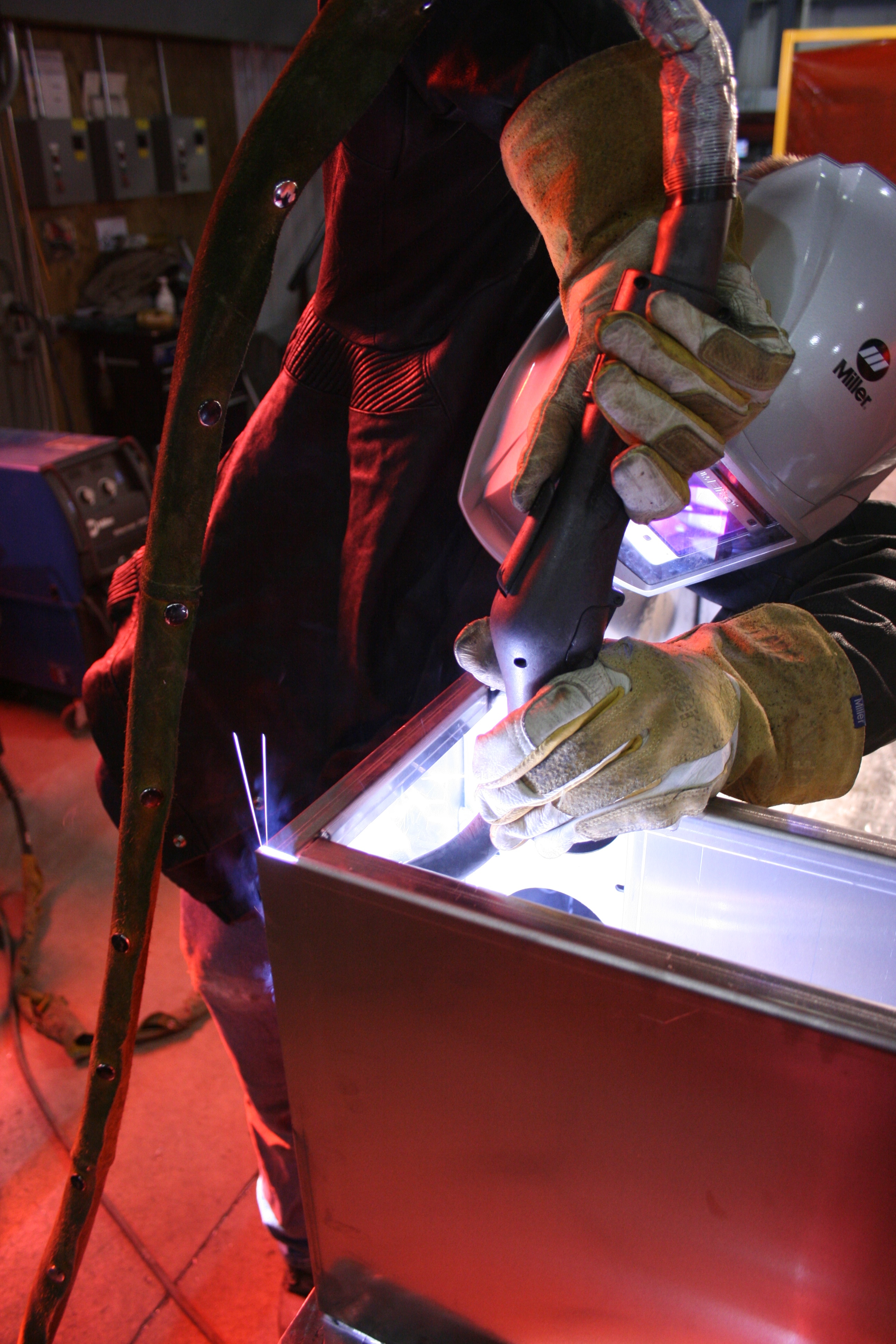

(click on photo to enlarge it)

(click on photo to enlarge it)

(click on photo to enlarge it)

(click on photo to enlarge it)

(click on photo to enlarge it)

(click on photo to enlarge it)

(click on photo to enlarge it)

Aluminum poses a unique set of challenges – especially when it comes to welding. It has a lower relative melting point than other metals, yet requires heat to ensure proper puddle formation. Cleanliness is critical. And it is more sensitive to heat input and distortion than other metals.

Welding aluminum has traditionally been a TIG welding application and, to be sure, there are applications where TIG is still best suited.

But new technology advances have made Pulsed MIG welding even more viable in applications where increased production speed is desired without sacrificing quality or appearance.

The key benefit of Pulsed MIG welding in aluminum welding applications is the balance between providing sufficient energy to ensure good fusion, yet controlling heat input to prevent warping or burn-through.

In Pulsed MIG welding, the welding power source rapidly and automatically switches between a high peak current (ensuring good fusion) and a low background current (lowers heat input and reduces distortion).

Because of the pulsing of the current, the operator can vary the heat input into the parts and weld thinner gauge material without burning through or warping the part.

It also creates improved aesthetics over conventional MIG welding and allows some manufacturers to standardize on a larger diameter wire for greater deposition, lower cost per pound, and simplification of inventory and equipment outlay.

In this article we will look at three manufacturers who have found recent successes with Pulsed MIG welding in aluminum applications: Greenheck Fan Corporation (Schofield, WI), Sportsfield Specialties (Delhi, NY), and Aluwind, Inc. (Castle Rock, CO).

STREAMLINED WELDING PROCESSES, SWITCHING BETWEEN METALS

Greenheck Fan is known worldwide as a leading manufacturer of quality air movement and control equipment. They offer the most comprehensive line of ventilation products in the industry, allowing a total air movement and control system to be specified from a single source.

As customer demand drove the company to shift much of its product to be fabricated of aluminum (lightweight, aesthetic versatility), the plant addressed the need to optimize its aluminum welding applications while maintaining the ability to weld mild, stainless and galvanized steels effectively.

The solution was an Invision™ MPa Plus System Pulsed MIG welding system that not only improved weld quality, but due to built-in efficiencies, also helped the plant streamline its welding operations.

http://youtu.be/bvcfx8Vyc5U

Matched with D-74 MPa Plus dual wire feeders, the system allows welders to quickly switch between two metals (typically aluminum and then a second wire such as stainless or silicon bronze).

Built-in MIG and Pulsed MIG programs automatically set the optimal parameters for a variety of wires, and the system simplified the welding operation by using Synergic Pulsed MIG Controls and Profile Pulse™.

“With Pulsed MIG programs, we can run higher wire speeds. Because of the better arc control, we run faster, flatten out our welds, get better control of our weld metal volume and eliminate overheating issues,” explains Dan Apfelbeck, the continuous improvement leader of fans and vents.

The Invision 352 MPa uses built-in Pulsed MIG programs for common 4000 and 5000 series aluminum wires ranging in diameter from .035 in to 1/16 in, as well as many of the other alloys (steel, stainless steel, silicon bronze, copper, nickel) found in the company product line.

Operators previously had to set their parameters independently, but this new system ensures consistency between operators and workstations, and helps ensure quality each time an arc is struck.

“It takes the skill level of our welding group here and makes them aluminum welders,” smiles Apfelbeck. “Welding aluminum isn’t the same as giving a guy a steel gun and saying, ‘Here, weld this’. It’s a different animal. This machine plays a key role in allowing our welders to transition from a being steel operators to aluminum operators.”

Working with Pulsed MIG equipment enabled the shop to eliminate its reliance on .035 in wire for certain applications and transition to 3/64 in (.047 in) aluminum wire.

“Using the new programs let us move to 3/64 in as our single wire diameter because we can now weld down to .050 in material with heavier wire and still eliminate burn-through and blistering,” notes Apfelbeck. “The larger wire diameter provides faster travel speeds, increased fill rates (deposition) and a lower cost per pound.”

It also allows the plant to simplify its equipment demands in certain departments. “In some areas, we’ve eliminated push-pull systems and gone to shorter push-only systems because of our ability to use the larger diameter wire,” adds Apfelbeck. “Our equipment outlay is much less. Maintenance and consumable costs have been reduced.”

Greenheck Fan Corporation, 400 Ross Avenue, Schofield, WI 54476, 715-359-6171, Fax: 715-355-2399, www.greenheck.com.

INCREASED WELDING PRODUCTION SPEED

Up to 50 tons per month of raw aluminum flows through the Aluwind plant in Castle Rock. Whether it comes in as sheet stock, square tube or profile stock, by the time it leaves the Castle Rock facility it has been fabricated into premium aluminum components for the wind tower industry.

Aluminum is the material of choice for Aluwind because it is relatively lightweight and easy to handle, and the plant has honed its aluminum fabrication and welding practices over 17 years in business.

The shop reserves the Pulsed MIG process for welding on aluminum materials thicker than 3 mm (1/8 in and up) because it provides greater production speeds without sacrificing quality.

The adjustability and performance of using a synergic AlumaFeed System enabled the shop to standardize on one type and size of wire (0.047 ER5356) and save considerable amounts of time through process efficiencies.

http://youtu.be/hbdUOCXpuK0