What You Must Know About Beveling or Weld Preparation

If beveling has typically been an afterthought in your shop, it could actually be costing you more in terms of quality and time than you realize, then examines some considerations about the beveling process and the equipment you should use that could improve your competitive advantage.

Posted: May 28, 2013

What type of beveling equipment does your fabricating business use? If the process of beveling has typically been an afterthought in your operation, it could actually be costing you more in terms of quality and time than you realize. It should come as no surprise that those shops that are the most productive, efficient and lucrative use beveling tools that require little set up, are lightweight and easy to handle, operate at a fast speed and present no health hazards to the operator.

http://youtu.be/jhYIOew9URI

There is no need for any fabricator to use the “Fred Flintstone” Stone Age method of beveling in today’s sophisticated metalworking environment. Modern beveling tools and techniques are being used by job shops of all sizes who find them to be an indispensable tool in their “competitive advantage” arsenal. We are going to explore some considerations related to your beveling operation and the equipment you should use, but first let’s define what beveling is and look at its basic tenets.

At its most basic level, beveling is a process used to prepare metal for a welded seam by cutting a slope at an angle on the edge of the metal. This weld preparation sequence is an integral part of building everything from simple metal cabinets to complex metal structures to erecting bridge work. In other words, beveling is used in such a widely diverse range of applications that the examples are virtually without limit (see Figure 1).

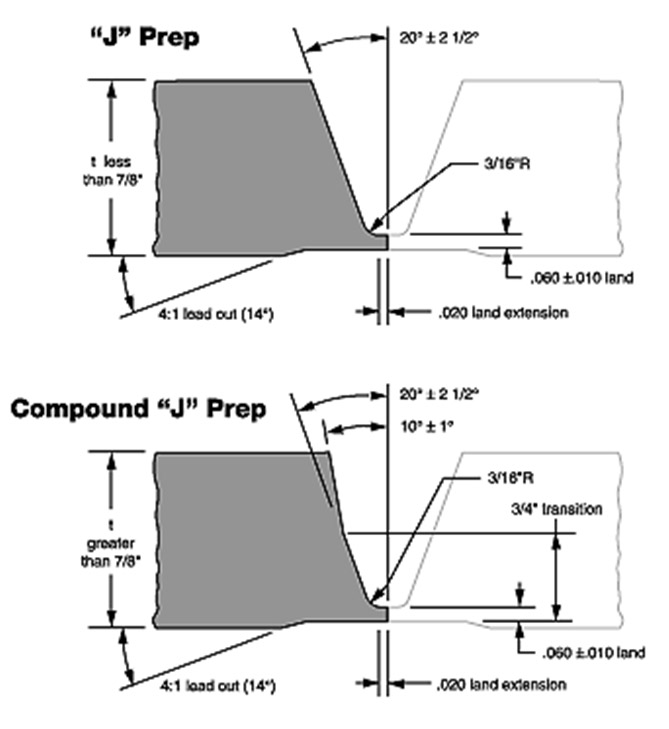

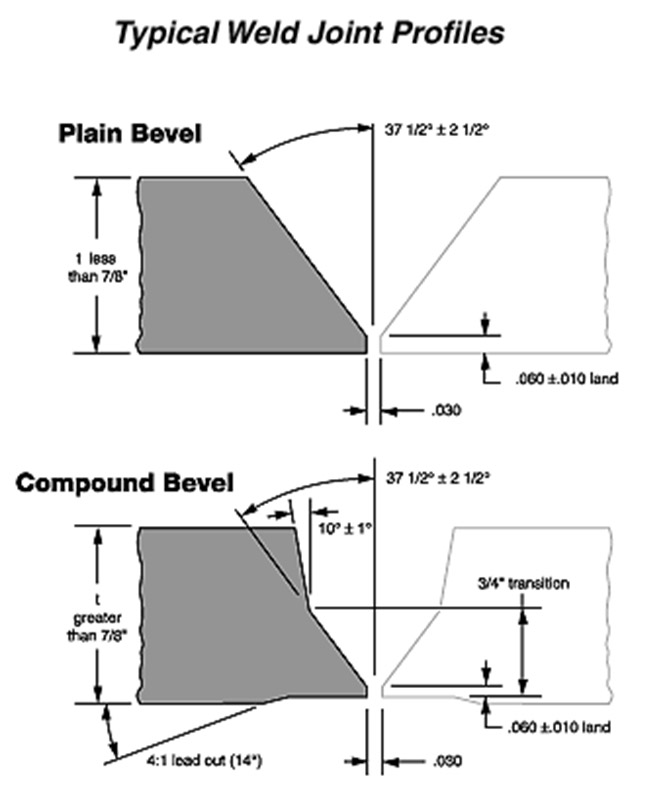

Some of the common symbols used to identify and describe the shaped welding joint configurations referred to in welding specifications are “V”, “double V”, “K”, and “Y”. As most of us know all too well, the shape of the surface to be welded is not always a straight flat plate. In some cases, the bevel may need to be put on a round or inside diameter, or a curved or radius surface. So when choosing your method to bevel, the shape configuration that is required should always be taken into consideration as part of the normal operating procedure when multiple pieces of metal must be assembled or welded together.

There are many ways to bevel. Hand grinding, flame cutting and machining are a few of the more typical methods that are currently used. It is important to note that the method one selects to use up front is an important key to realizing a successful final outcome. The factors for the method that is selected are usually determined by the specification taken from the manufacturer’s drawing or blueprint and will normally contain the following information that must always be taken into consideration when beveling:

THE DEGREE OF ANGLE

Different angles apply to different applications. In most cases of beveling pipe, for example, the standard bevel is a 37.5 deg angle. That is not the case for other types of metal applications. The important thing to remember is this: whatever the degree, being able to keep that angle within the tolerance level is one critical key to a good bevel.

THE LENGTH OF THE BEVEL

Another important factor in achieving a good bevel is its length, which is the length of material removed to allow the weld bead to be laid into the materials. This is typically measured by the hypotenuse of the angle (see Figure 1). It is important to have a consistent length of bevel because that consistency ensures an easier operation downstream when the welding is done. A more consistent bevel serves to reinforce the weld and makes it stronger simply because the integrity remains the same throughout the piece being welded together.

This dimension is also sometimes measured as the “land,” which is the portion of material left on the work piece (see Figure 1). No matter how it is measured, accuracy is obviously most important. The more consistent these dimensions are, the easier and stronger the welding operation itself will be.

SPEED

Speed is always a factor in any machining operation and in beveling it is no different. While the term time is money is a cliché, it really rings true here. Your method of beveling should be a technique that is done in the absolute fastest cycle time possible.

DO NOT HEAT THE METAL THAT IS BEING WELDED TOGETHER

Sometimes the term “heat-affected zone” is mentioned in the weld specifications. When metal you purchase is originally produced, different alloys such as chromium, magnesium or iron are combined in varying levels to comprise the required structural characteristics of the metal being ordered for your specific job. Afterwards, if heat is applied to this metal as it is being worked on, the micro-structural characteristics of that alloy composition can change inside the metal. This means that heating the metal by working on it can ultimately change the material you originally purchased into a different metal that could affect and/or change many other components of your operation.

HEALTHY BEVELING

A critical issue that must not be overlooked is that weld preparations or beveling must be monitored for the unhealthy fumes that are produced during the operation. When certain metals are heated, fumes are released by the combination of the heat and the metal. Always know what specific metals are being used when working with a heat source. In fact, when certain metal is heated it can produce a very toxic vapor and if your workers are not using proper ventilation or masks, there exists a real potential for a serious health risk. This critical factor should never be overlooked nor minimized.

EFFICIENT, PRODUCTIVE BEVELING

To competitively address all of these obstacles in beveling, you should select the proper beveling tool that meets your needs. Some of the most efficient beveling tools ever built are now available in the market today. They have no noticeable heat influence and, therefore, no dangerous fumes. This type of beveling equipment performs a process that produces no dust and no vapors or gases, so it avoids the micro-structural changes in the metal and prevents any chemical processes from taking place.

When adding a beveling tool to your fabricating operation, ask these questions:

- Is the beveler emission-free (no toxic fumes)?

- Will you be able to produce oxide-free cutting edges?

- What is the machine’s speed?

- Are the types of welds you will be making radius or curved applications?

- Is it easy to adjust?

Although beveling may often be an afterthought in some shops, spending a little time to assess your needs in this area can result in a big payback in terms of saving time, preserving quality – and gaining competitive advantage.

Subscribe to learn the latest in manufacturing.