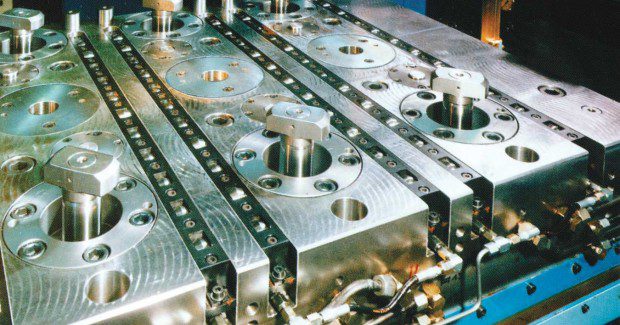

Hydraulic Quick Die Change Systems

The concept of quick die change is simple: minimize the time from the last good hit on one die to the first good hit on the next one.

Posted: March 27, 2013

Hilma hydraulic die change systems can be customized to a shop's presses to better meet its business needs.

With 50 years of experience in clamping dies, the Hilma Division of Carr Lane Roemheld Mfg. Co. (Ellisville, MO) provides safe, reliable hydraulic die clamping systems that offer faster turnaround, reduced labor costs, consistent part quality through a broad range of clamps, die lifters, hollow piston cylinders, hydraulic circuits, pumps, control panels and other products for quick die change.

Advantages of Hilma Hydraulic Die Change Systems include:

- Customized to your press, and your needs

- High clamping forces

- Optimum selection of clamping positions

- Repeatability of positioning and clamping

- Clamping at hard-to-get-to points

- More capacity

- Reduced scrap and cleanup time

For more information visit www.clrh.com.

Subscribe to learn the latest in manufacturing.

Whether you’re cutting metal, stamping, bending, folding, shearing or rolling up your sleeves to tackle other day-to-day jobs, ensuring equipment is in tip-top shape is critical to a Job Done RightTM. Thankfully, by giving equipment a little TLC, facilities can not only run smoothly, but also up the ante on efficiency and productivity.

Whether you’re cutting metal, stamping, bending, folding, shearing or rolling up your sleeves to tackle other...